Revolutionize Your Production: Discover the Power of Dispersing Agent MF (Methyl Naphthalene Sulfonate Formaldehyde) – Anionic Surfactant for Textile Dyes, Construction Concrete, Leather Tanning, and Rubber Stabilization – Unparalleled Performance and Stability

Experience superior material dispersion with Dispersing Agent MF, engineered to enhance dye brightness, fortify concrete, optimize leather processing, and stabilize rubber, ensuring peak performance across diverse industrial applications.

Get a Quote & SampleUnlocking Superior Material Dispersion with Dispersing Agent MF

Dispersing Agent MF

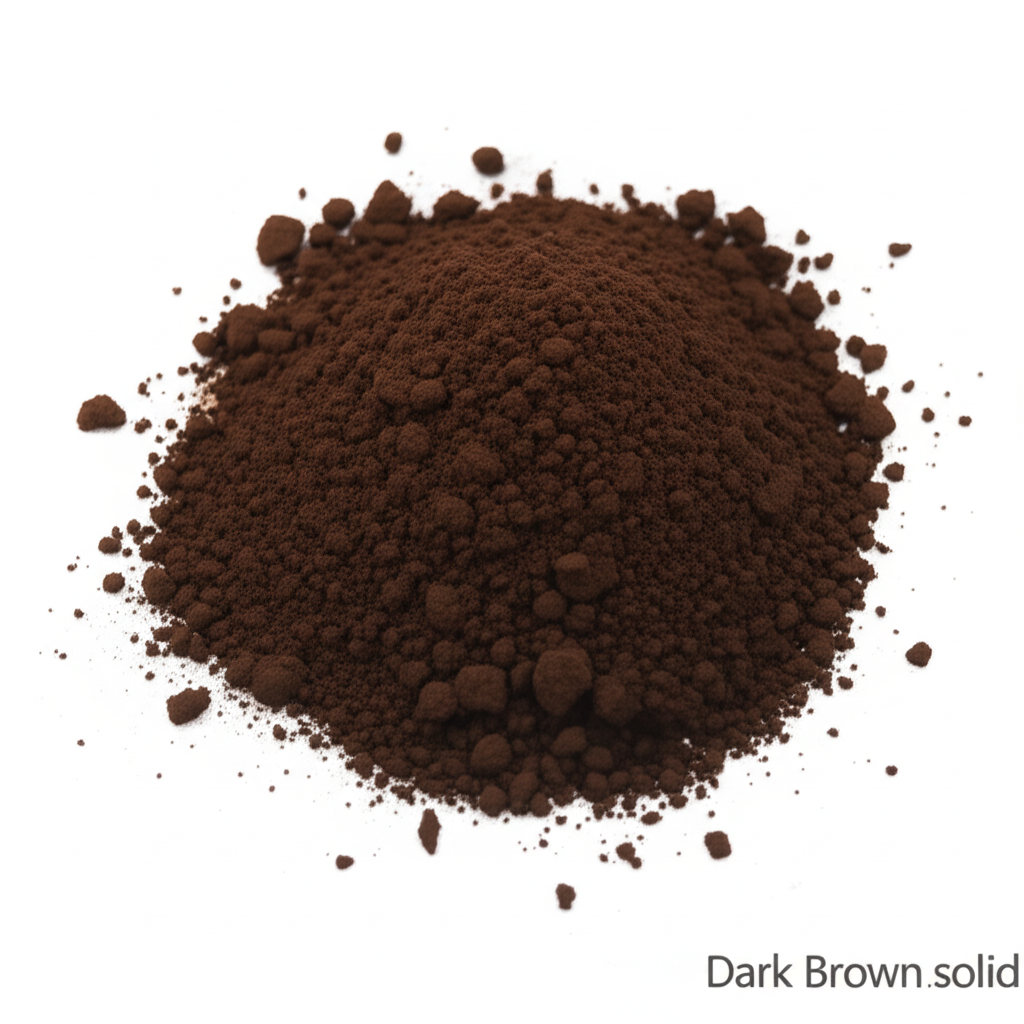

Dispersing Agent MF, chemically known as Methyl Naphthalene Sulfonate Formaldehyde condensate (CAS 9084-06-4), is a highly effective anionic surfactant presented as a dark brown powder. It excels in preventing particle agglomeration, ensuring uniform distribution in various liquid systems. Its robust chemical profile, including resistance to acids, alkalis, and hard water, makes it an indispensable component for demanding industrial processes.

- Enhance your textile dyeing processes: Our Dispersing Agent MF for textile dyeing ensures finer dye particles, leading to brighter, more uniform colors and increased color strength.

- Fortify construction materials: As an essential Dispersing Agent MF in concrete admixture, it significantly reduces water requirements while improving workability and achieving stronger, more durable concrete structures.

- Optimize leather and rubber production: Utilize our premium Dispersing Agent MF for leather tanning to enhance chemical penetration and as a rubber latex stabilizer, ensuring product consistency and quality.

- Discover the broad applications of CAS 9084-06-4: This versatile compound extends its benefits to papermaking, wettable pesticides, and pigment dispersion, highlighting its unparalleled performance.

Key Advantages of Using Dispersing Agent MF

Superior Dispersion & Stability

Dispersing Agent MF boasts excellent dispersibility, keeping solid particles evenly suspended and preventing agglomeration. Its high thermal stability ensures consistent performance even in challenging high-temperature processes, making it a reliable solution for various industrial needs, including high temperature stable dispersant MF applications.

Enhanced Product Quality

By ensuring uniform distribution and preventing clumping, Dispersing Agent MF helps achieve brighter, more vibrant colors in dyes, stronger concrete, and improved consistency in rubber and leather products. It directly contributes to the overall quality and aesthetic appeal of your final products, proving its value across diverse sectors.

Broad Compatibility & Safety

This non-toxic and non-irritating anionic surfactant exhibits strong compatibility with other anionic and non-ionic agents, offering formulation flexibility. Its resistance to acids, alkalis, hard water, and inorganic salts guarantees stable performance in complex chemical environments, while being safe to handle for manufacturers seeking a reliable Methyl Naphthalene Sulfonate Formaldehyde supplier.

Key Applications

Textile & Dyeing Industry

Dispersing Agent MF is vital for vat dyes and disperse dyes, enhancing grinding efficiency and color uniformity. It is extensively used in pad dyeing and high-temperature dyeing processes to achieve brilliant and consistent colors, making it indispensable for any textile dye dispersant MF supplier.

Construction Sector

Acting as an effective water-reducing agent, MF Dispersing Agent significantly improves concrete workability and strength, shortens construction periods, and saves cement, crucial for modern construction projects looking to buy Dispersing Agent MF for concrete.

Leather & Rubber Industries

In the leather industry, it functions as an auxiliary tanning agent, improving leather quality and durability. For rubber and latex, it serves as a stabilizer, preventing particle clumping and ensuring product consistency during manufacturing, a key benefit for the rubber latex stabilizer MF dispersant market.

Papermaking & Other Specialties

It optimizes pulp processing, reduces two-sidedness, and improves filler retention in papermaking. Additionally, its uses extend to wettable pesticides, electroplating, water-soluble coatings, and carbon black dispersion, demonstrating the wide applicability of Dispersing Agent MF CAS 9084-06-4.