Unlocking the Potential of Polysulfone (PSU) Granules

Discover the exceptional properties and diverse applications of PSU granules for your advanced material needs.

Get a Quote & SampleProduct Core Value

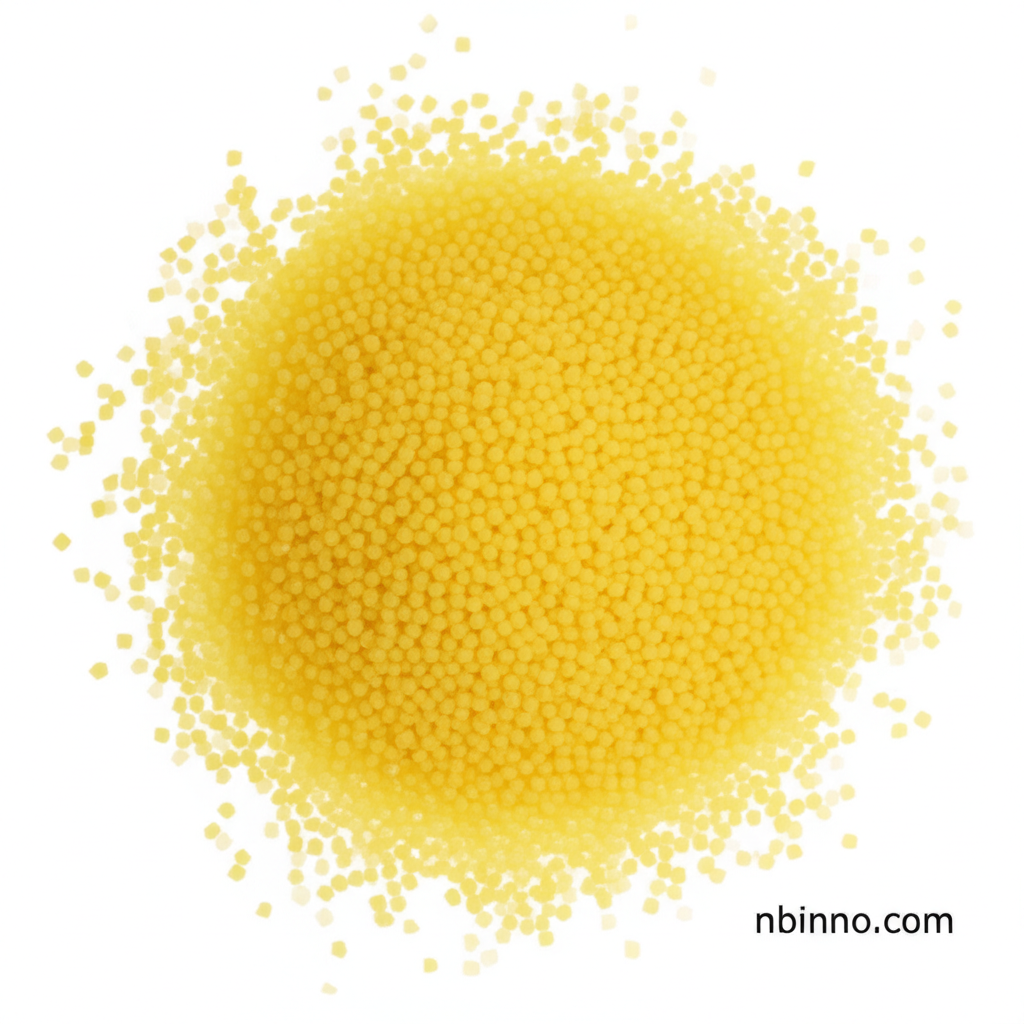

Polysulfone Granules

Polysulfone (PSU) granules are a state-of-the-art thermoplastic polymer renowned for their exceptional combination of mechanical strength, thermal stability, and chemical resistance. These properties make them indispensable for high-stakes applications across numerous industries, offering reliability and performance even under extreme conditions.

- Explore the diverse PSU granule applications, including their use in demanding medical device manufacturing, where biocompatibility and sterilization resistance are paramount.

- Understand the unique CAS 25135-51-7 material properties of PSU, such as its high glass transition temperature and excellent hydrolysis resistance, ensuring performance in critical environments.

- Investigate the high-performance polymer solutions offered by PSU, particularly its ability to maintain structural integrity at elevated temperatures and resist degradation from aggressive chemicals.

- Learn about the electrical insulation polysulfone capabilities, making it ideal for automotive electrical components and electronic applications requiring superior dielectric strength and reliability.

Key Advantages Provided by Polysulfone

Exceptional Thermal Stability

PSU granules offer superior high-temperature performance, maintaining their mechanical properties and dimensional stability even when exposed to prolonged heat, which is crucial for many industrial applications.

Superior Chemical Resistance

Benefit from the remarkable chemical inertness of Polysulfone PSU properties, allowing it to withstand exposure to a wide range of acids, alkalis, and hydrocarbons without degradation.

High Mechanical Strength and Rigidity

The inherent strength and rigidity of Polysulfone make it an excellent choice for components requiring structural integrity, contributing to the longevity and reliability of the final product.

Key Applications

Medical Devices

The biocompatibility and sterilization resistance of medical grade polysulfone make it ideal for surgical tools, filtration membranes, and other critical medical equipment.

Aerospace Components

Leverage the high-temperature and chemical resistance of aerospace polysulfone components for demanding applications within the aerospace sector, ensuring safety and reliability.

Automotive Electrical Systems

The excellent electrical insulation properties of automotive electrical polysulfone make it suitable for connectors, insulators, and other components exposed to heat and vibration.

Industrial Filtration

The chemical inertness and thermal stability of industrial filtration membranes made from PSU are vital for efficient and durable separation processes in various industries.