Advanced Dyeing Wetting Agents for Textile Processing: Enhance Uniform Dyeing, Penetration & Fabric Quality – Your Essential Auxiliary for Superior Textile Finishing Results.

Achieve unparalleled color consistency and efficiency in your textile production with our innovative wetting agents, designed for vibrant, consistent results every time.

Get a Quote & SampleUnlock Superior Textile Quality with Our Advanced Wetting Agents

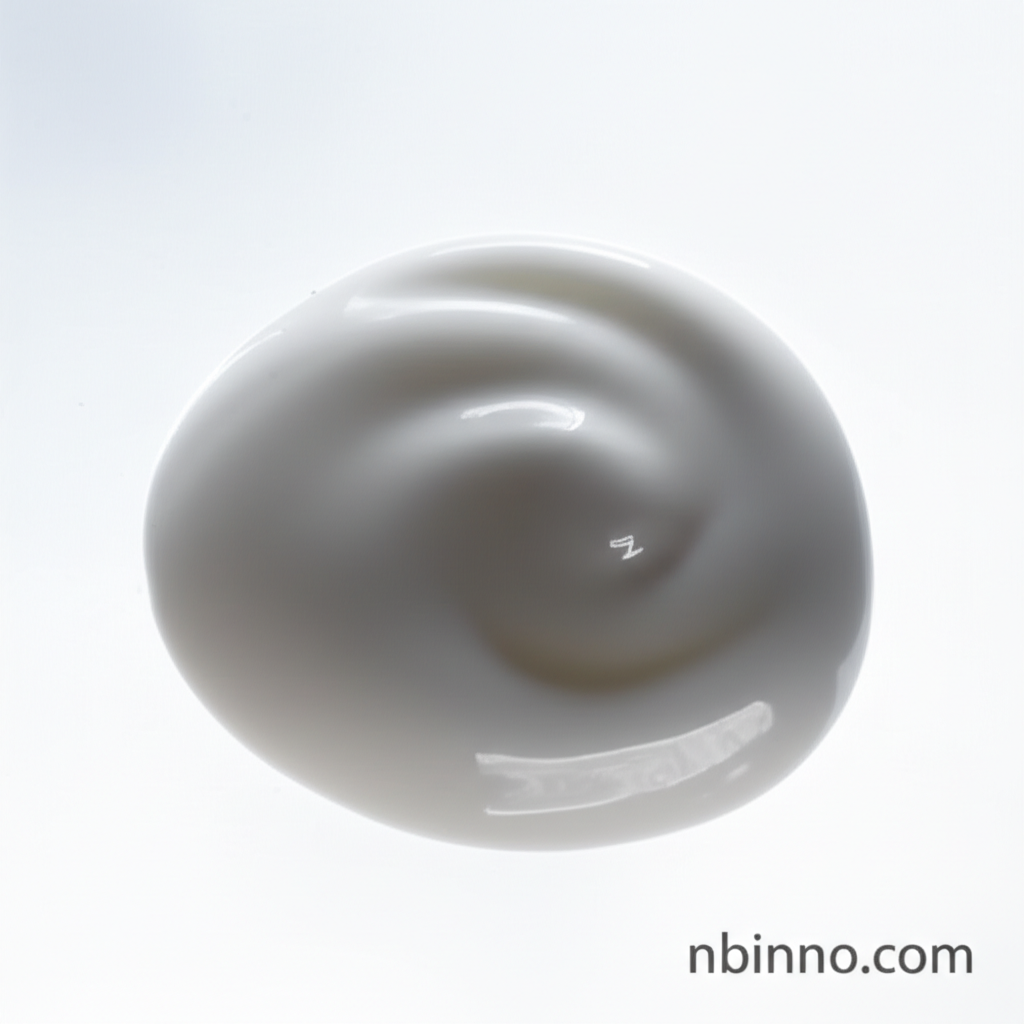

Dyeing Wetting Agents

Our advanced dyeing wetting agents are crucial textile auxiliaries designed to significantly improve fabric quality and dyeing efficiency. These agents act as surfactants, effectively reducing water's surface tension to ensure superior penetration of dyes and chemicals into various fabric fibers, including cotton, polyester, and blends. They facilitate uniform dye distribution, prevent streaks and uneven shades, and optimize dye adsorption for vibrant, consistent colors.

- Enhance dye penetration in textile materials, ensuring that dyes and chemicals reach deep into fabric fibers for richer, more uniform colors.

- Facilitate impurity removal during textile pretreatment, preparing fabrics optimally for subsequent dyeing processes and preventing defects.

- Achieve uniform dyeing auxiliary chemical performance across various fabric types, minimizing color discrepancies and improving overall product quality.

- Benefit from our eco-friendly fabric penetration enhancer, promoting sustainable manufacturing practices without compromising on performance or safety.

Key Advantages Our Wetting Agents Deliver

Superior Wetting & Dispersion

Our dyeing wetting agents excel at reducing surface tension, which is essential for uniform dyeing. This property allows for a rapid and even spread of liquids across the fabric, crucial for high efficiency fabric wetting agent applications in complex textile processes.

Optimized Dyeing Process

By ensuring excellent dye penetration, our products contribute significantly to an improved textile process efficiency. This minimizes processing times and reduces the likelihood of imperfections, making them indispensable for any textile dyeing operation.

Environmentally Responsible Solution

Committed to sustainability, our wetting agents are formulated to be environmentally friendly. This ensures compliance with modern ecological standards while delivering superior performance, supporting a greener textile industry.

Key Applications

Textile Pretreatment

Our wetting agents are vital for textile pretreatment, preparing fabrics by effectively removing impurities like oils and waxes. This critical step ensures that the fabric is clean and ready for optimal dye uptake, preventing issues like uneven dyeing.

Textile Dyeing

Central to textile dyeing, these agents promote uniform dye distribution across various fibers, including cotton and polyester. They ensure deep and even color absorption, making them a crucial uniform dyeing auxiliary chemical for vibrant and consistent results.

Textile Printing

In textile printing, our wetting agents ensure precise and sharp prints by allowing printing pastes to spread evenly and penetrate effectively. This leads to clearer patterns and enhanced color brilliance, boosting the quality of printed fabrics.

Fabric Finishing

Beyond dyeing, our wetting agents contribute to fabric finishing processes, improving the absorption of various finishing chemicals. This aids in achieving desired fabric properties like softness, wrinkle resistance, and water repellency, ensuring overall fabric quality.