Mastering Polyurethane: A Deep Dive into Polymethylene Polyphenyl Polyisocyanate

Discover the versatility and power of Polymethylene Polyphenyl Polyisocyanate (PMDI), a cornerstone chemical for high-performance polyurethane applications.

Get a Quote & SampleProduct Core Value

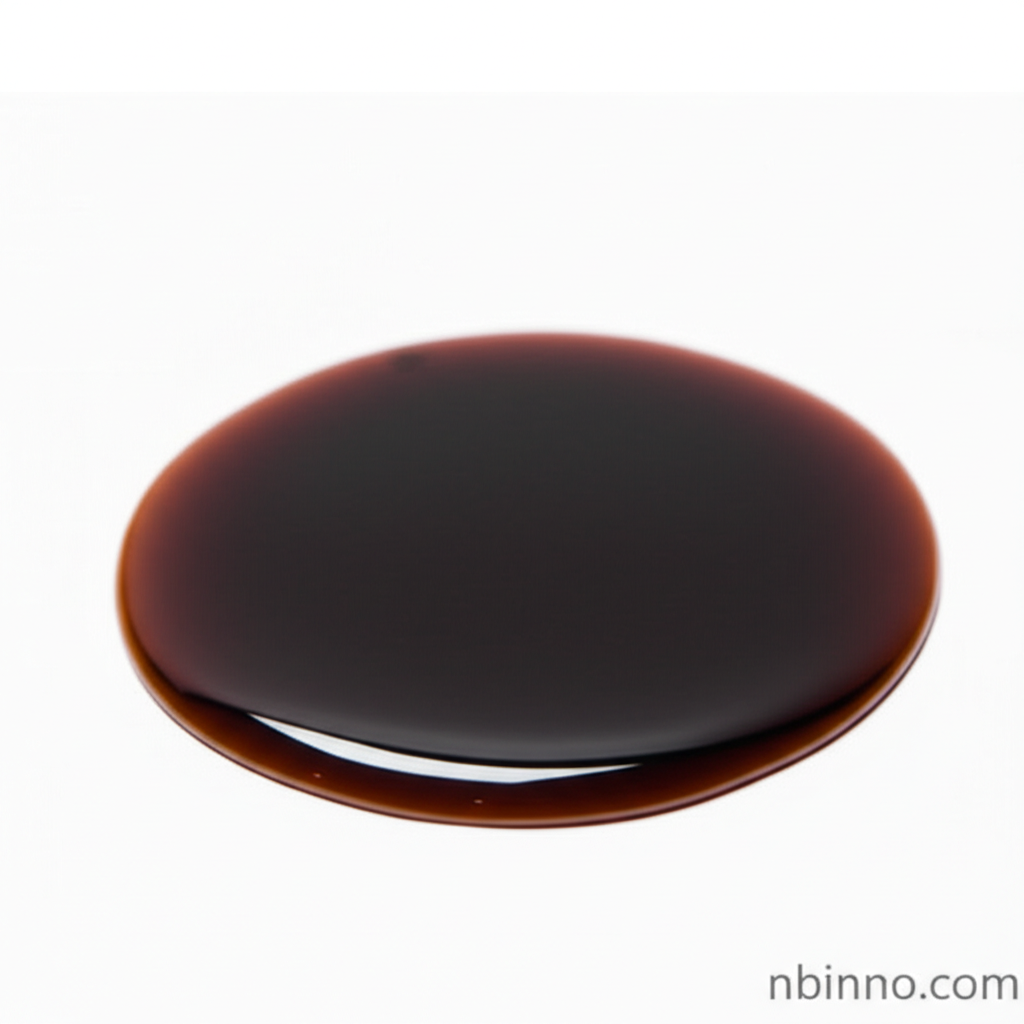

Polymethylene Polyphenyl Polyisocyanate

Polymethylene Polyphenyl Polyisocyanate (PMDI), also known as Polymeric MDI, is a critical component for producing advanced polyurethane materials. Its chemical structure and reactivity make it ideal for creating durable and high-performance products across various industries. This versatile chemical intermediate plays a vital role in numerous manufacturing processes, contributing significantly to the properties of end products.

- Leverage the Power of Polyurethane Foam: Explore how PMDI is a key raw material in polyurethane foam applications, essential for insulation materials in buildings and appliances, showcasing its importance in energy efficiency.

- Enhance Coating and Adhesive Performance: Understand the critical role of PMDI as a chemical auxiliary in coatings and adhesives, providing superior bonding and protective properties for diverse substrates.

- Utilize High Functionality Isocyanate: Benefit from the high functionality of PMDI, a characteristic that allows for complex polymer network formation, leading to materials with excellent mechanical strength and durability.

- Discover Versatile Application Uses: Learn about the broad spectrum of applications for PMDI, including its use in rubber auxiliaries, plastic additives, and textile applications, demonstrating its wide-ranging industrial utility.

Advantages of PMDI

Enhanced Material Properties

PMDI's unique chemical composition contributes to the development of polyurethane materials with exceptional mechanical strength, thermal stability, and chemical resistance, outperforming many traditional materials.

Versatile Processing Capabilities

As a brown liquid at room temperature, PMDI offers good foam fluidity properties, making it suitable for manufacturing products with demanding specifications for foaming stock solutions. Its manageable viscosity aids in processing efficiency.

Broad Industrial Applicability

From rigid foam insulation and isocyanurate foams to coatings, adhesives, and structural components, PMDI is a key ingredient that drives innovation and performance across multiple industrial sectors, including automotive and construction.

Key Applications

Polyurethane Rigid Foam Insulation

PMDI is extensively used in the manufacturing of rigid polyurethane foam insulation materials, contributing to energy efficiency in buildings and appliances through superior thermal resistance.

Industrial Coatings and Adhesives

Discover how PMDI enhances the performance of coatings and adhesives, providing robust protection and strong bonding for applications in automotive, construction, and manufacturing industries.

Automotive Components

Explore the use of PMDI in automotive parts such as bumpers and interior trim, where its properties contribute to durability, safety, and aesthetic appeal in vehicle manufacturing.

Synthetic Wood and Structural Foams

PMDI is vital for creating synthetic wood materials and structural foams, offering a versatile and cost-effective alternative to traditional wood in construction and manufacturing.