Polyepichlorohydrin: Properties, Applications, and Advantages in Coatings and Adhesives

Discover the versatile properties and extensive applications of Polyepichlorohydrin in advanced material solutions.

Get a Quote & SampleProduct Core Value

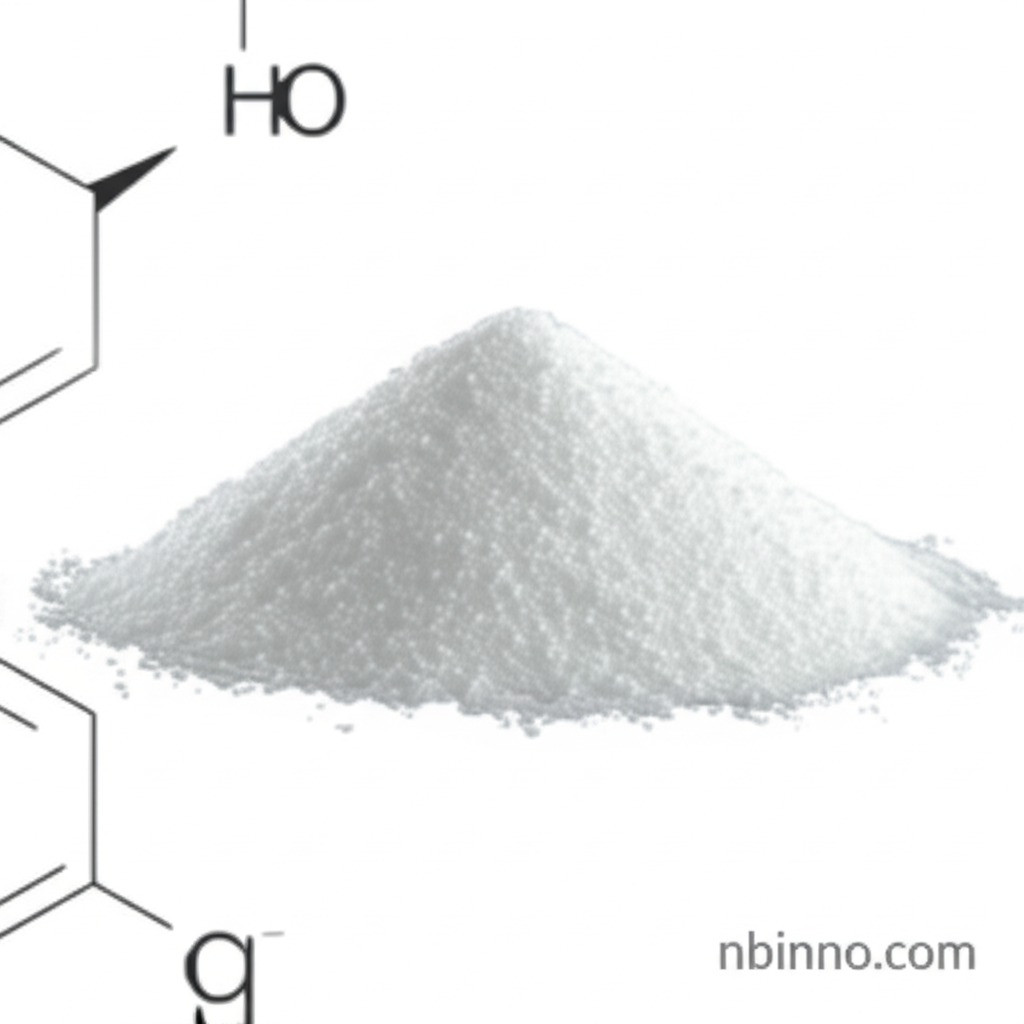

Polyepichlorohydrin

Polyepichlorohydrin, also identified as Resin epoxy, is a high-performance chemical compound with CAS number 24969-06-0. It boasts a remarkable assay of 99% and presents as a colorless solid, ensuring high purity for critical applications. Its low hydrolyzed and inorganic chlorine content makes it suitable for demanding environments. The product's defined softening point, volatile matter, and color/lustre specifications underscore its quality and consistency, making it a reliable choice for industrial applications.

- Leverage the benefits of high purity (99%) with low chlorine content, making polyepichlorohydrin ideal for sensitive applications.

- Explore the extensive uses of polyepichlorohydrin in anticorrosive coatings and specialized adhesive formulations for electronics.

- Discover why heat-resistant coatings for electrical appliances often rely on the robust properties of polyepichlorohydrin.

- Understand the crucial role of polyepichlorohydrin in laminating processes and its contribution to building corrosion resistant engineering.

Key Advantages of Polyepichlorohydrin

Superior Chemical Resistance

Polyepichlorohydrin offers exceptional resistance to corrosive agents, ensuring long-term protection for surfaces, a critical aspect of building corrosion resistant engineering.

Excellent Thermal Stability

This resin is utilized in making heat-resistant coatings for electrical appliances, demonstrating its capability to withstand elevated temperatures without degradation.

Versatile Application in Adhesives

Its strong bonding capabilities make polyepichlorohydrin a prime choice for various adhesives, including those used for demanding applications like IC printing boards.

Key Applications

Anticorrosive Coatings

Polyepichlorohydrin is extensively used in anticorrosive coatings to protect metal surfaces from degradation, extending the lifespan of infrastructure and equipment.

Industrial Adhesives

As a robust component in adhesives, it provides strong bonding for diverse materials used in building, aviation, and ship applications.

Electrical Insulation

The material is vital for creating high-quality insulation materials, ensuring safety and performance in electronic components and electrical appliances.

Powder Coatings

Its properties make it a suitable ingredient for powder coatings, offering durable and aesthetically pleasing finishes for various products.