Accurate Humidity Monitoring: Understanding the 3-Dot Humidity Indicator Card for PCB and Electronics Protection

Safeguard your sensitive electronics with reliable visual humidity indication.

Get a Quote & SampleProduct Core Value

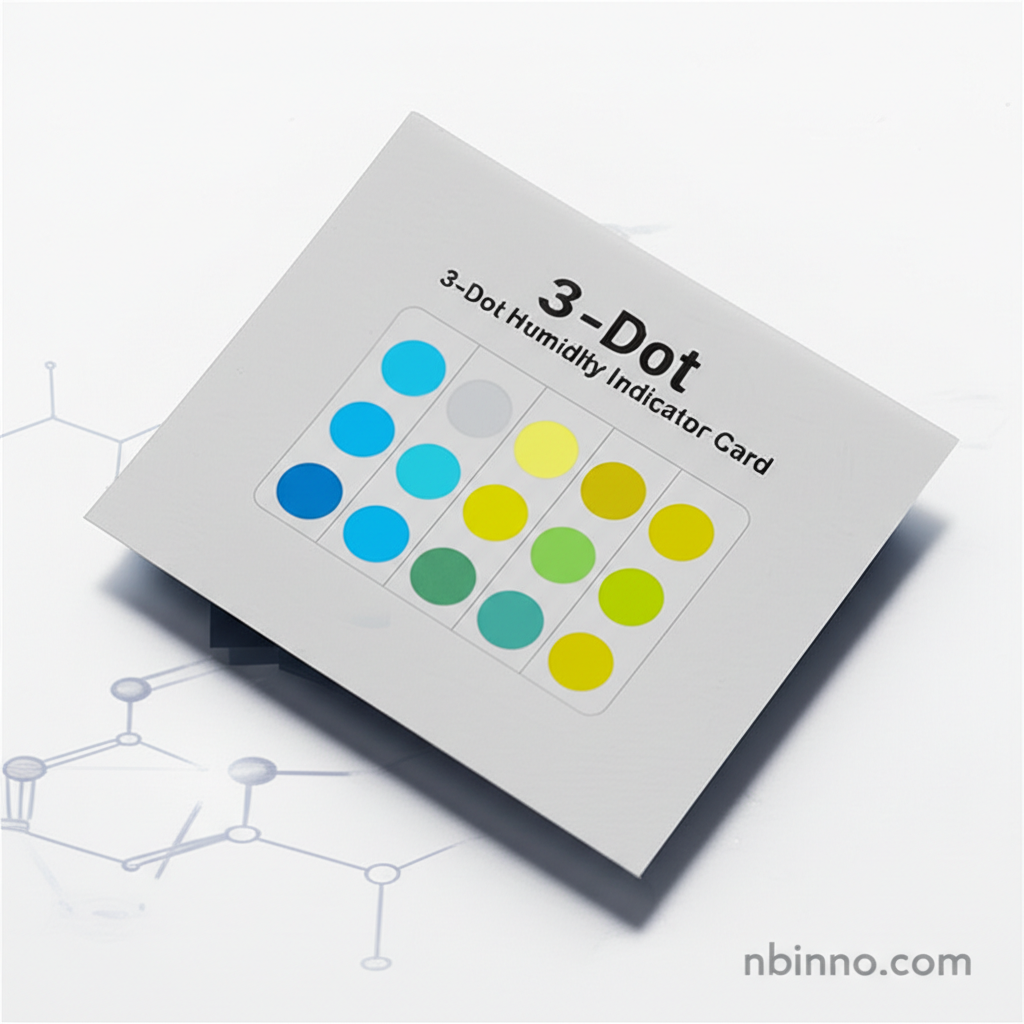

3-Dot Humidity Indicator Card

The 3-dot humidity indicator card is an essential tool for anyone involved in the packaging and handling of moisture-sensitive components, particularly within the PCB and electronics industries. Its primary function is to provide a clear, visual indication of the relative humidity (RH) levels inside a sealed package. This card is designed to work in conjunction with desiccants and moisture barrier bags, forming a comprehensive system for protecting delicate electronics from the detrimental effects of moisture.

- Introduction to PCB Moisture Monitoring: Understanding the criticality of maintaining low RH levels is paramount for the longevity and functionality of printed circuit boards and electronic components.

- How to Use Humidity Indicator Card: Proper placement and interpretation are key. These cards offer a simple yet effective way to visually assess if moisture has entered the packaging.

- Desiccant and Humidity Indicator Card Synergy: These components work hand-in-hand. Desiccants absorb excess moisture, while the indicator card verifies the effectiveness of the barrier and desiccant over time.

- Protecting Electronics from Moisture: By using these cards, manufacturers can confirm that their packaging solutions are effectively preventing moisture ingress, thereby avoiding issues like corrosion and component degradation.

Key Advantages

Cost-Effective Moisture Detection

As a low-cost method for verifying packaging effectiveness, the 3-dot humidity indicator card offers significant value in preventing costly product damage.

Visual Assurance of Package Integrity

Providing immediate visual feedback, these cards offer assurance that the internal environment of the package remains within acceptable humidity limits.

Enhanced Product Lifespan

By enabling proactive intervention when humidity levels rise, these cards contribute to maintaining product quality and extending the lifespan of sensitive electronic components.

Key Applications

Electronics Manufacturing

Essential for ensuring the quality and reliability of electronic components throughout their lifecycle, from manufacturing to end-use.

PCB Packaging

Critical for protecting printed circuit boards from moisture damage during storage and transit, maintaining their pristine condition.

Semiconductor Handling

Vital for safeguarding moisture-sensitive semiconductors, preventing 'popcorning' and ensuring their performance integrity.

Optical Component Preservation

Used to protect delicate optical components from humidity-induced degradation, ensuring clarity and performance.