Chemical Devulcanization: The Key to Sustainable Rubber Recycling

Unlock the potential of waste rubber through advanced chemical devulcanization, fostering a circular economy and environmental responsibility.

Get a Quote & SampleProduct Core Value

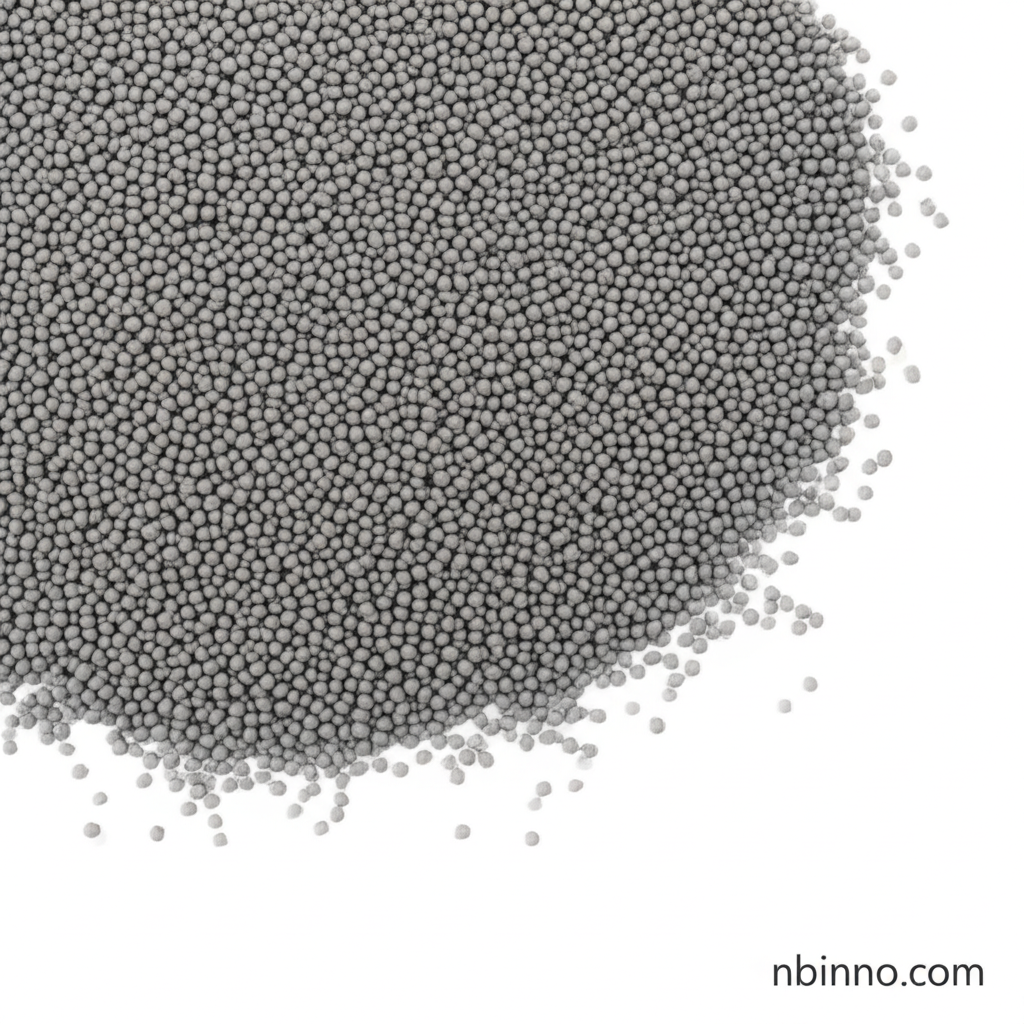

Rubber Recycling Chemical Agent

This chemical agent is pivotal in the rubber recycling process, specifically enabling effective devulcanization. By targeting the cross-linked sulfur bonds within vulcanized rubber, it allows the material to be reprocessed and repurposed, significantly reducing landfill waste and promoting a circular economy. The goal is to repurpose vulcanized rubber chemicals for sustainable manufacturing.

- Leveraging chemical devulcanization for rubber recycling processes breaks down the robust structure of waste rubber, making it viable for new applications.

- The agent plays a crucial role in the devulcanization agents rubber waste transformation, enhancing material properties for reuse.

- By using these agents, industries can significantly improve their rubber recycling process benefits, leading to cost savings and reduced environmental impact.

- This approach supports a more sustainable rubber reprocessing chemicals model, aligning with global environmental goals.

Advantages Offered

Environmental Sustainability

Utilizing chemical devulcanization is a cornerstone of sustainable rubber reprocessing chemicals, drastically cutting down on landfill waste and the environmental burden associated with rubber disposal.

Material Repurposing

The agent facilitates the transformation of discarded rubber into valuable materials, contributing to the circular economy in polymer industries and reducing reliance on virgin resources.

Cost-Effectiveness

By enabling the reuse of existing rubber materials, this process offers significant cost savings compared to the production of new rubber, enhancing the economic viability of rubber recycling.

Key Applications

Industrial Rubber Goods

Devulcanized rubber can be incorporated into the manufacturing of various industrial components, showcasing innovative devulcanization methods in action.

Automotive Components

Recycled rubber finds applications in automotive parts, demonstrating the practical environmental benefits of rubber repurposing.

Construction Materials

The processed rubber can be used in construction materials, highlighting its versatility and contribution to sustainable building practices.

Consumer Products

From footwear to mats, recycled rubber enhances the sustainability of consumer goods, embodying the principles of advanced rubber recycling technologies.