Dioctyl Phthalate (DOP): Enhancing PVC Flexibility

Discover the key applications and benefits of Dioctyl Phthalate, a vital plasticizer for flexible PVC products.

Get a Quote & SampleProduct Core Value

Dioctyl Phthalate

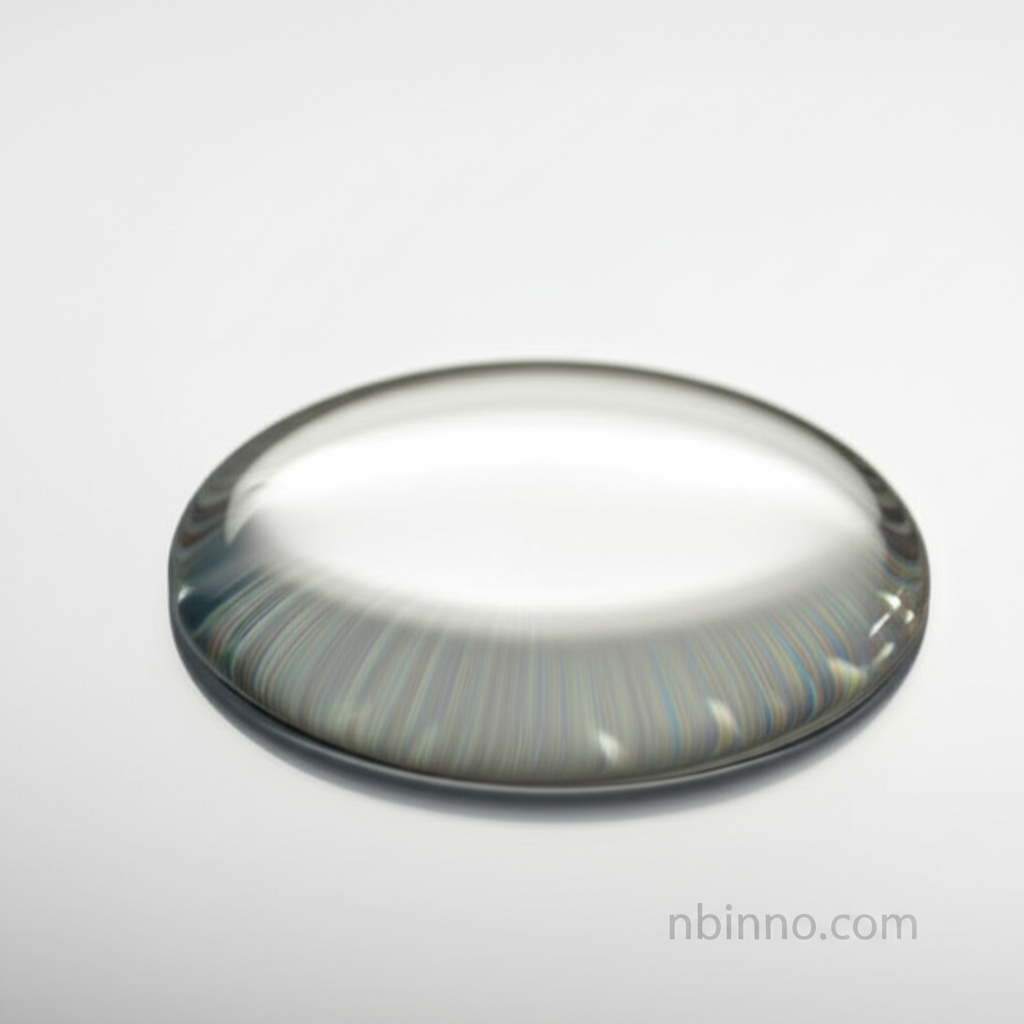

Dioctyl Phthalate (DOP) is a cornerstone plasticizer, renowned for its ability to impart exceptional flexibility and ductility to PVC. Its chemical structure, C24H38O4, and CAS number 117-81-7, describe a colorless to pale yellow oily liquid with a mild odor. DOP boasts excellent solubility in organic solvents and insolubility in water, making it an ideal additive across a wide spectrum of industrial applications.

- Discover the advantages of using Dioctyl Phthalate as a plasticizer for flexible PVC products, enhancing their performance and lifespan.

- Explore the chemical properties of DOP, understanding its role in making plastics more pliable and manageable in manufacturing processes.

- Learn about the versatility of Dioctyl Phthalate, a key component in the production of items ranging from electrical wires to essential medical devices.

- Understand the importance of this plasticizer for electrical wires and cables, ensuring their flexibility and durability under various conditions.

Key Advantages

Enhanced Flexibility

DOP significantly improves the flexibility and ductility of PVC, allowing for the creation of a wider range of adaptable products, essential for flexible PVC applications.

Broad Compatibility

Its wide compatibility with PVC resins and other materials makes DOP a reliable choice for achieving desired material properties in various manufacturing processes.

Cost-Effectiveness

As a widely used industrial plasticizer, DOP offers a cost-effective solution for enhancing the properties of PVC, supporting competitive pricing for end products.

Key Applications

Electrical and Cable Manufacturing

DOP is crucial for producing flexible PVC compounds used in electrical wires and durable cables, ensuring insulation and pliability.

Synthetic Leather and Textiles

In the production of synthetic leather and textiles, DOP contributes to the softness, drape, and overall tactile quality of the materials.

Medical Devices

DOP is utilized in manufacturing essential medical devices, providing the necessary flexibility for items like infusion tubes and medical tubing.

Flooring and Construction

The application of DOP extends to durable flooring materials and construction components, enhancing their resilience and ease of installation.