Reactive Thickener CY-316B: Elevating Textile Printing with Superior Viscosity Control and Vibrant Color Yield

Discover how our advanced reactive thickener redefines fabric printing, delivering unparalleled color brilliance and precise pattern definition for your textiles.

Get a Quote & SampleProduct Core Value

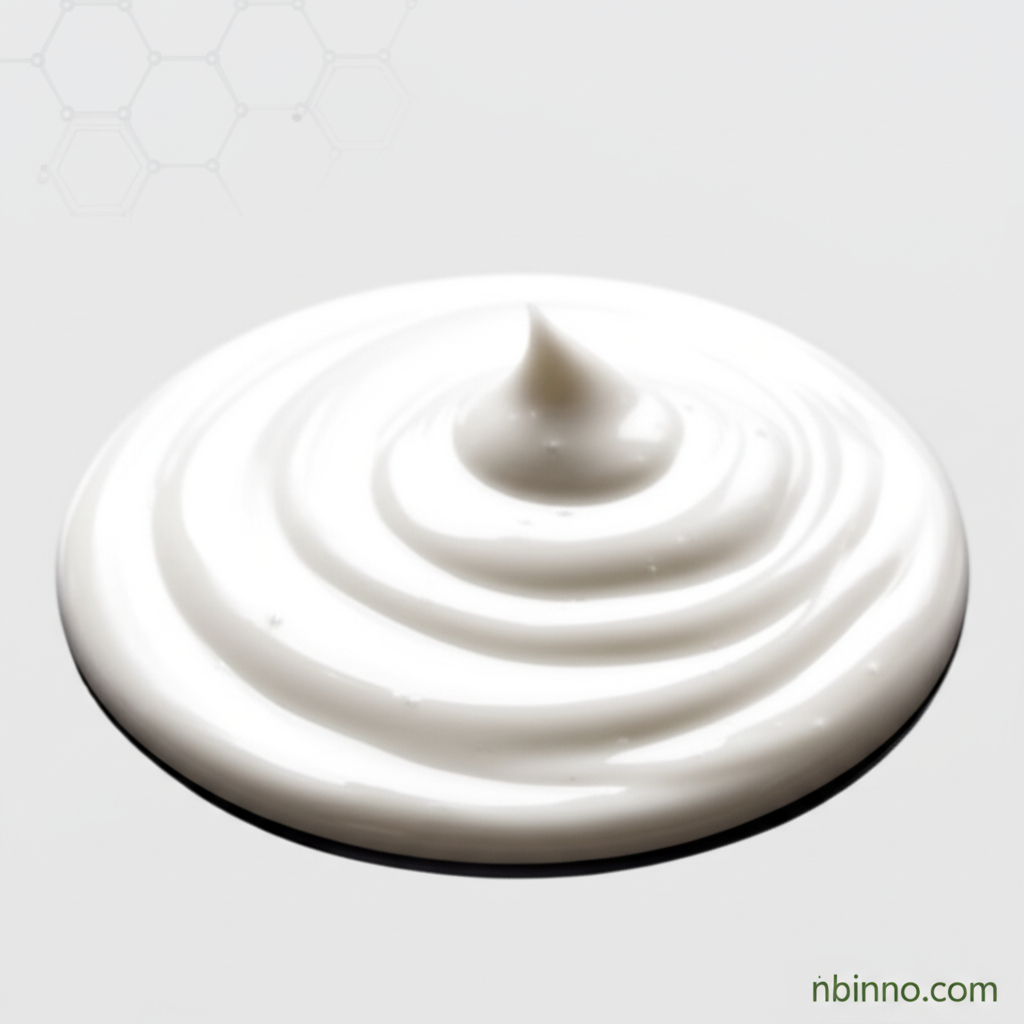

Reactive Thickener CY-316B

Reactive Thickener CY-316B is a high-performance chemical auxiliary designed to optimize the rheological properties of printing pastes, ensuring efficient and high-quality reactive printing. This advanced textile printing chemical enhances the overall process by providing stable viscosity and excellent printability, making it a cornerstone for producing premium printed fabrics.

- High viscosity: Ensures better control over the printing paste, preventing dye migration and providing clear outlines, crucial for textile reactive printing.

- Superior fluid performance: Facilitates easy passage through printing screens, optimizing efficiency in both rotary screen printing and flat screen applications.

- Enhanced color yield: Contributes to vibrant color yield and brilliant color presentation on treated fabrics, meeting high aesthetic demands.

- Electrolyte resistant: Offers good resistance to electrolytes, maintaining stability and performance even in complex dye formulations, a key benefit for dyeing auxiliaries.

Product Advantages

Unmatched Print Definition

Achieve sharp, crisp designs with superior water holding ability and clear outlines, setting new standards in fabric printing excellence.

Cost-Effective Production

Its high concentration and efficient performance reduce overall consumption, offering a smart solution for textile chemical manufacturers aiming for cost savings.

Environmental Compliance & Safety

Certified with OEKO-TEX® Standard 100 and REACH, ensuring your products meet stringent international environmental protection requirements, making it an eco-friendly reactive thickener.

Key Applications

Textile Reactive Printing

Indispensable for creating high-definition patterns on cellulosic fibers, ensuring precise application for reactive dyes.

Fabric Pre-treatment

Plays a vital role in preparing fabrics for dyeing and printing, contributing to the overall quality and efficiency of textile pre-treatment processes.

Rotary & Flat Screen Printing

Specifically formulated to provide optimal rheology for various screen printing techniques, crucial for large-scale textile production.

Cellulosic Fabric Dyeing

Enhances the adhesion and fixation of reactive dyes on cotton, rayon, and their blends, leading to durable and vibrant fabric coloration.