Formaldehyde-Free Disperse Thickener KR-712: Enhancing Rotary Printing Quality and Efficiency

Discover KR-712: The eco-friendly, high-performance solution that revolutionizes your textile printing, ensuring vibrant colors, sharp patterns, and a superior fabric feel.

Get a Quote & SampleRevolutionizing Textile Printing with Eco-Friendly KR-712

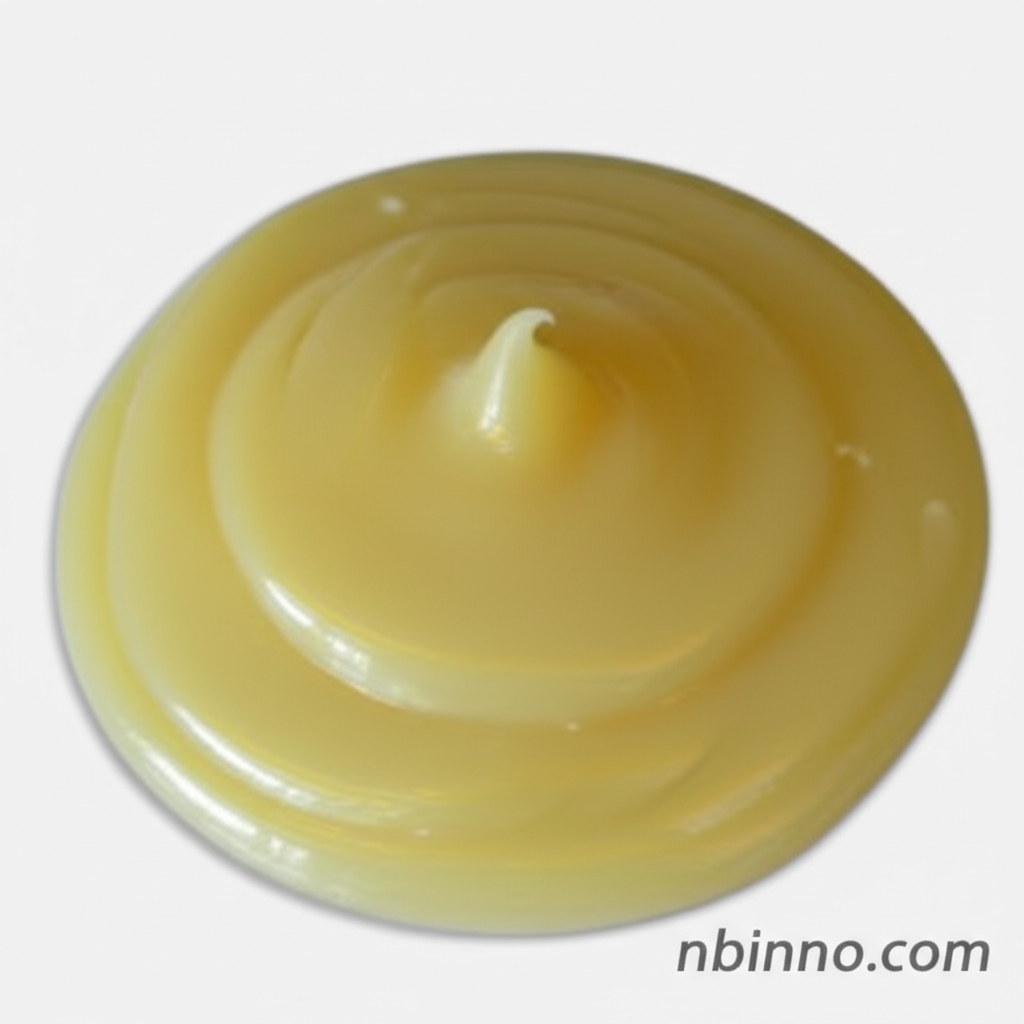

KR-712 Disperse Printing Thickener

KR-712 Disperse Printing Thickener is engineered to transform your textile printing operations. As a formaldehyde-free and APEO/NPEO-free solution, it aligns with modern environmental standards while delivering unparalleled performance. This advanced thickener ensures brilliant color yield and crisp pattern definition, elevating the quality of your printed fabrics.

- Achieve high color vibrancy with our formaldehyde free textile thickener for rotary printing, ensuring your designs stand out with brilliance.

- Experience precise pattern definition and outstanding penetration, crucial for high-quality rotary printing and sharp graphics.

- Replace traditional sodium alginate with a cost-effective and superior performing alternative, optimizing your printing paste for better results.

- Ensure a soft fabric feel and easy wash-off, simplifying textile post-processing auxiliary steps and enhancing product comfort.

Unleashing Superior Performance: Key Advantages of KR-712

Eco-Conscious & Cost-Effective

KR-712 is a leading environmentally friendly textile thickener supplier choice, being formaldehyde-free and APEO/NPEO-free. This commitment to sustainability also comes with significant cost savings, making the KR-712 thickener for textile an economically smart choice.

Exceptional Print Quality

Benefit from the superior thickening performance of KR-712, ensuring excellent stability and precise pattern definition. This results in high color vibrancy and clear, sharp prints, enhancing the overall aesthetic of your textile products.

Enhanced Fabric Feel & Processing

The unique properties of KR-712 ensure outstanding penetration during printing and are incredibly easy to wash off. This leaves the fabric with a notably soft feel, streamlining your post-processing auxiliary workflow and reducing residue, optimizing your textile production.

Key Applications

Rotary Textile Printing

Specifically designed for rotary printing, KR-712 provides optimal viscosity control for precise and consistent application of disperse dyes on synthetic fabrics, ensuring high color vibrancy and sharp pattern definition.

Flat Printing Techniques

Beyond rotary applications, KR-712 also excels in flat printing, offering reliable thickening for various design complexities and fabric types, leading to precise pattern definition and superior results.

Synthetic Fiber Dyeing

As a key textile printing auxiliary, KR-712 supports enhanced dye uptake and ensures brilliant color yield when used with disperse dyes on polyester and polyester blended fabrics, making it an ideal choice for advanced disperse dye applications.

Textile Post-Processing

Its easy wash-off property makes KR-712 an ideal post-processing auxiliary, contributing to improved fabric hand-feel and reducing water consumption during finishing stages, supporting overall textile production cost optimization.