Boost Your Plastic Performance with Our Solvent-Free Additive

Enhance your compounds with superior processing and properties using our advanced silicone-based solution.

Get a Quote & SampleProduct Core Value

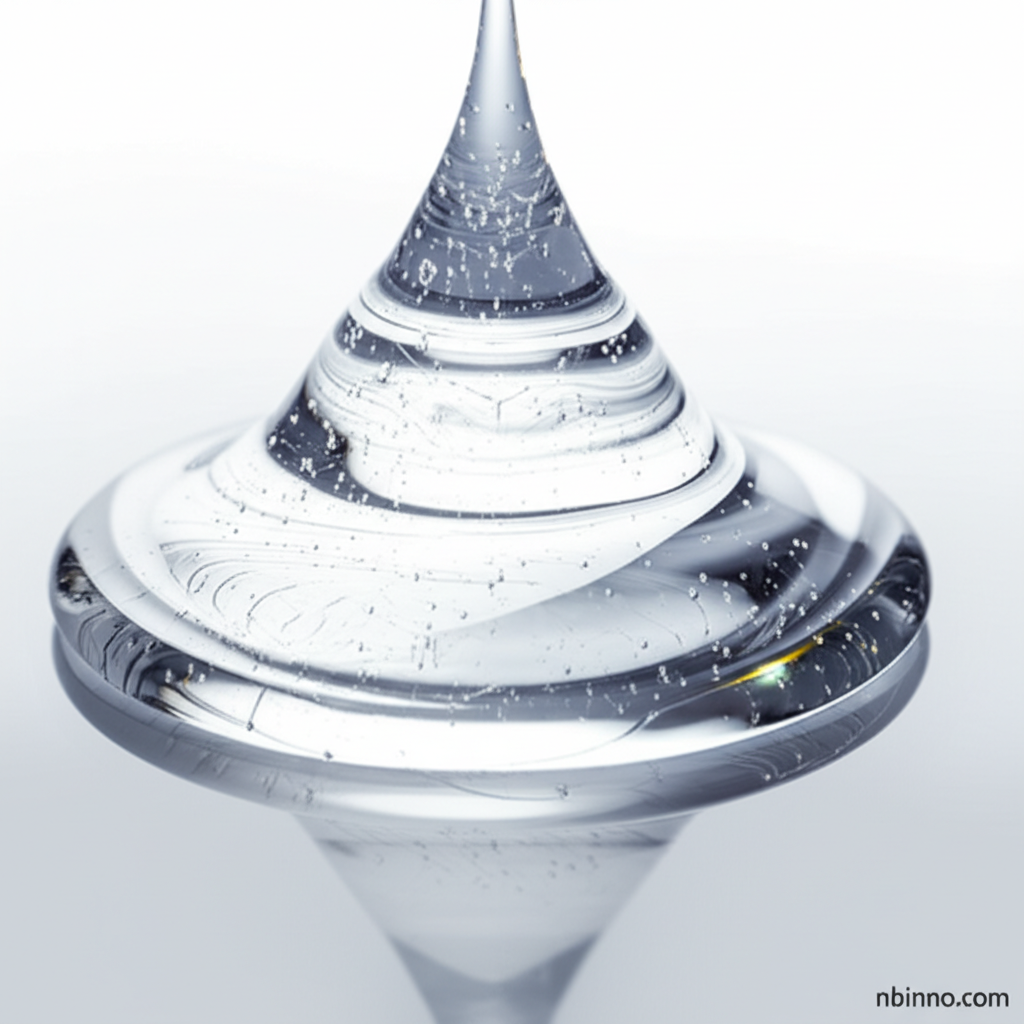

Solvent-free Additive of Plastic Compounds

Discover the revolutionary solvent-free additive designed to elevate your plastic compounds. This reactive polysiloxane with vinyl functionality is your direct replacement for Tegomer V-Si 4042, offering unmatched benefits in viscosity reduction and improved surface characteristics for extrusion products.

- Enhance Filler Dispersion and Flame Retardant Properties: Optimize your highly loaded compounds by improving the dispersion of fillers and boosting flame retardant capabilities, crucial for meeting safety standards.

- Improve Mechanical Properties and Processing Fluidity: Achieve superior processing fluidity and release performance in rubber products, leading to significantly better mechanical properties in your final compounds.

- Lower Viscosity and Improve Surface Characteristics: Streamline your EPM/EPDM compound processing by lowering viscosity and achieving better surface finishes on extrusion products.

- A High-Performance Processing Aid Solution: Replace traditional processing aids like stearic acid, paraffin, EBS, and PE wax with our advanced additive for enhanced results and efficiency.

Key Advantages

Enhanced Product Quality

Achieve superior mechanical properties and surface finishes, raising the standard for your plastic and rubber applications.

Improved Processing Efficiency

Benefit from significantly improved processing fluidity and release performance, streamlining your manufacturing workflow.

Superior Performance

Leverage the power of reactive polysiloxanes to enhance filler dispersion and boost flame retardant properties in your compounds.

Key Applications

Plastic Compound Enhancement

Improve the dispersion of fillers and enhance flame-retardant properties, directly impacting the performance and safety of plastic compounds.

Rubber Product Improvement

Serve as a high-performance processing aid for cables, shoes, and other rubber products, improving fluidity and mechanical properties.

EPM/EPDM Processing

Lower viscosity and improve the surface characteristics of extrusion products when used in the processing of EPM/EPDM compounds.

General Chemical Auxiliary

Widely applicable as a chemical auxiliary in various industries including oil drilling, water treatment, coatings, textiles, and paper.