High-Performance Thiuram Rubber Accelerator for Enhanced Vulcanization Efficiency

Achieve superior rubber product quality with our advanced thiuram disulfide vulcanization accelerator.

Get a Quote & SampleProduct Core Value

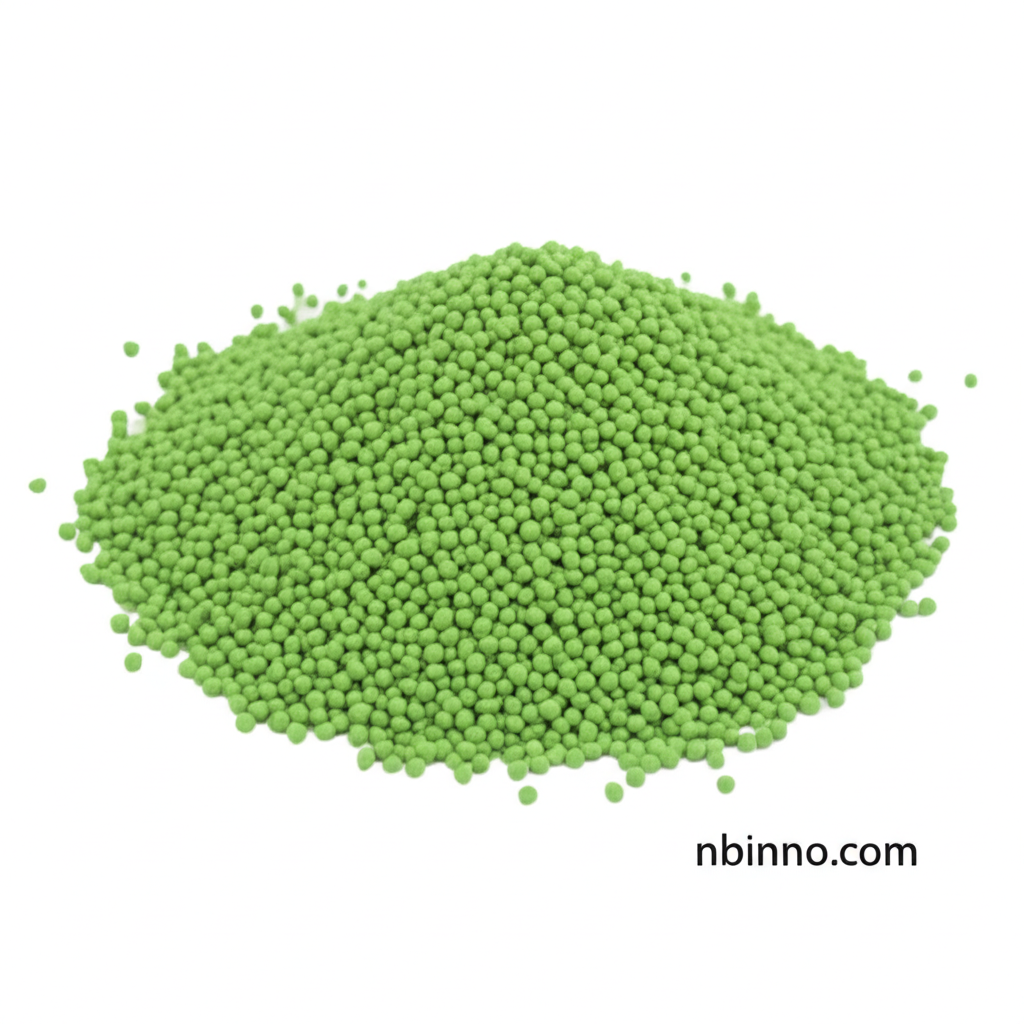

Tetrabutyl Thiuram Disulfide 50% EPDM+Oil+Dispersant

Our Tetrabutyl Thiuram Disulfide is a premium rubber accelerator designed for super-rapid vulcanization processes in various rubber applications. It enhances the performance and safety of rubber products.

- Leverage the benefits of a super rapid vulcanization accelerator for synthetic rubber in your manufacturing processes.

- Ensure enhanced burn-in safety for rubber injection moulding products, leading to better product consistency.

- Utilize this versatile rubber vulcanization agent, known for its ability to provide a finish free from frosting and contamination.

- Prioritize a safer manufacturing environment with a no nitrosamine rubber accelerator, contributing to compliant end products.

Key Product Advantages

Superior Vulcanization Speed

Experience faster cure times, significantly boosting production efficiency for your rubber manufacturing, as highlighted by the benefits of our super rapid vulcanization accelerator for synthetic rubber.

Enhanced Product Quality

Achieve rubber products free from frosting and contamination, ensuring a cleaner and more aesthetically pleasing finish, a key advantage of this specialized rubber vulcanization agent.

Improved Safety Profile

Contribute to a healthier workplace and safer products by using our no nitrosamine rubber accelerator, a crucial feature for compliance and responsible manufacturing.

Key Applications

Inner Tube Manufacturing

Our thiuram rubber accelerator for inner tubes ensures optimal performance and durability in automotive and bicycle applications.

Rubber Shoe Production

Enhance the quality and longevity of rubber footwear with our accelerator, vital for rubber shoe production.

Industrial Rubber Goods

Critical for industrial rubber products, this accelerator provides the necessary properties for demanding applications.

Rubber Injection Moulding

The improved burn-in safety makes it ideal for rubber injection moulding, ensuring consistent results for complex shapes.