Explore the Versatility of Dimethyl Silicone Oil

Discover the exceptional properties and diverse applications of Dimethyl Silicone Oil (PDMS) across multiple industries.

Get a Quote & SampleUnveiling the Core Value of PDMS

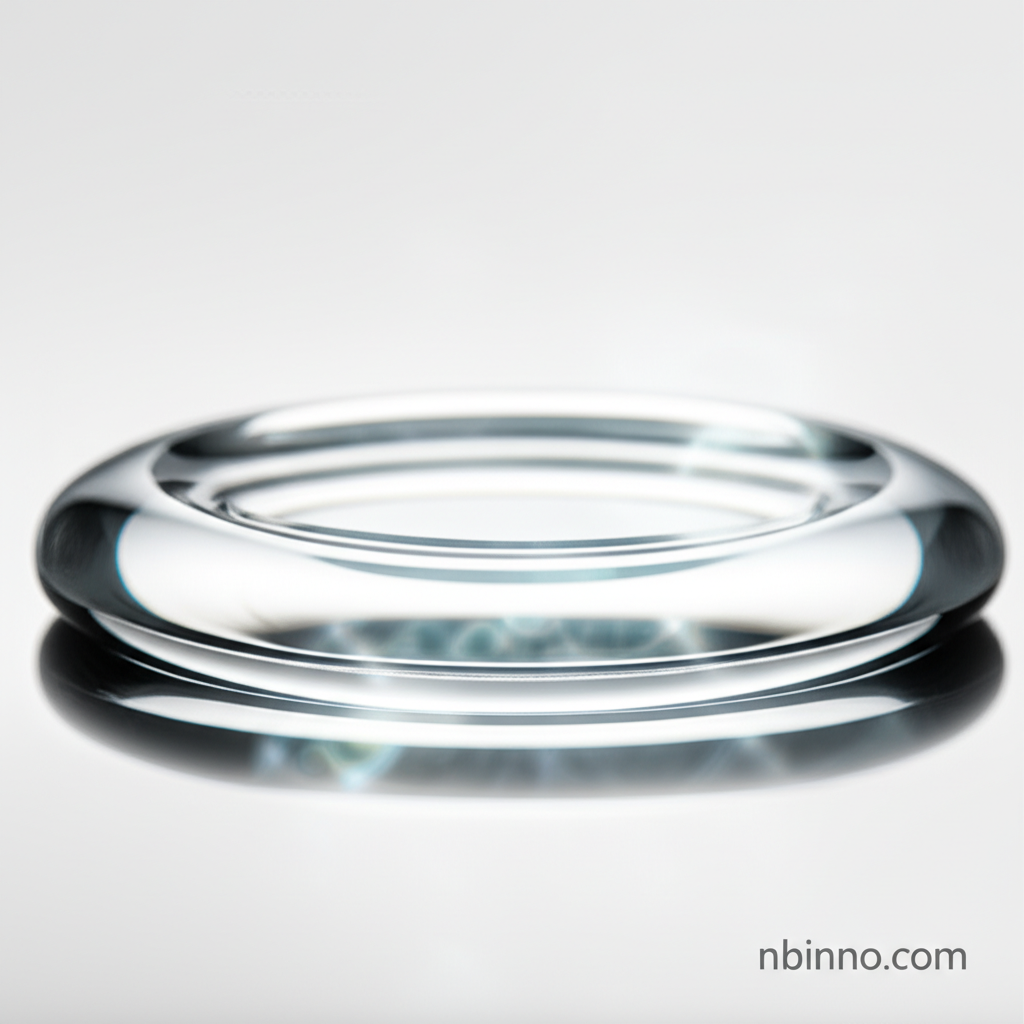

Dimethyl Silicone Oil

Dimethyl Silicone Oil, also known as Polydimethylsiloxane (PDMS), is a high-performance silicone polymer celebrated for its exceptional chemical stability, thermal resistance, and unique rheological properties. It offers a wide range of viscosities, making it adaptable for numerous industrial and consumer applications.

- Explore the wide range of dimethyl silicone oil applications, from advanced coatings to personal care formulations.

- Understand the key benefits of using polydimethylsiloxane in various industrial processes and product developments.

- Learn about the distinct silicone oil properties that make it a preferred choice for demanding applications.

- Discover how dimethyl silicone oil functions effectively as a lubricant in sectors requiring high performance and durability.

Key Advantages of Dimethyl Silicone Oil

Exceptional Chemical Inertness

Experience the reliability of this chemically inert fluid, essential for many industrial processes where compatibility is key. Its resistance to breakdown ensures consistent performance.

Superior Thermal Stability

Benefit from the high and low temperature resistance of PDMS, allowing for consistent application across a broad thermal spectrum, a crucial aspect for many industrial uses.

Excellent Water Repellency

Utilize the inherent hydrophobicity of Dimethyl Silicone Oil to enhance water resistance in various materials, from textiles to construction coatings.

Key Applications

Textile Industry

In the textile sector, PDMS serves as a softener and lubricant for sewing threads, improving processing and reducing thread breakage during high-speed operations.

Cosmetics and Personal Care

Dimethyl silicone oil is a vital ingredient in skincare and hair care products, providing smoothness, hydration, and a non-greasy feel, contributing to the 'silicone oil properties' sought after by consumers.

Industrial Lubrication

As a high-grade lubricant, Dimethyl Silicone Oil offers superior performance in mechanical and electronic equipment due to its thermal stability and low viscosity-temperature coefficient, showcasing its 'dimethyl silicone oil lubricant' capabilities.

Coatings and Sealants

Its water-repellent and weather-resistant qualities make PDMS an ideal additive for coatings, sealants, and construction materials, enhancing durability and performance.