Enhance Polyamide and Polypropylene Blends with High-Performance EPDM-g-MAH Compatibilizer

Unlock superior material performance with advanced compatibilization for your polymer formulations.

Get a Quote & SampleProduct Core Value

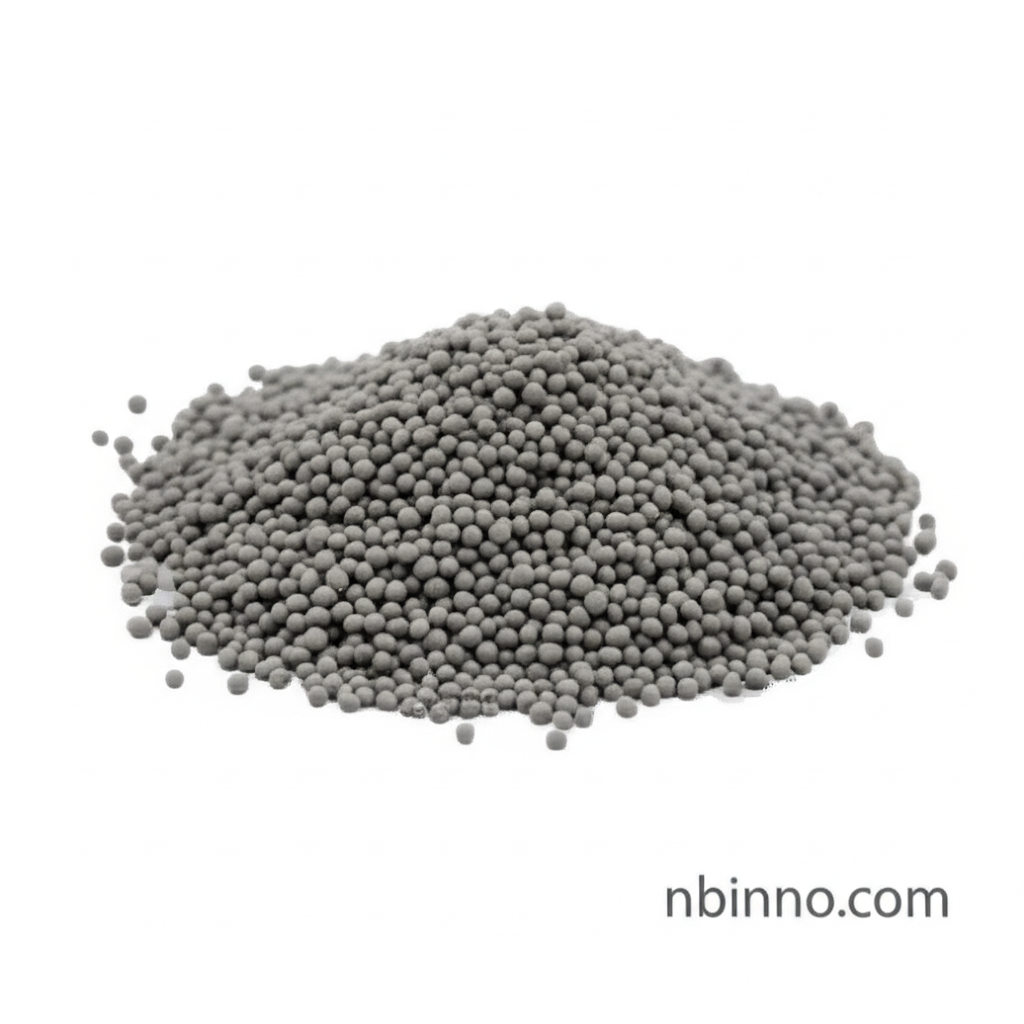

Maleic Anhydride Grafted EPDM

Discover the power of maleic anhydride functionalized ethylene propylene diene monomer (EPDM-g-MAH) in transforming your polymer blends. This advanced elastomer is engineered for exceptional anti-fatigue properties and robust aging resistance, making it an indispensable additive for high-demand applications.

- Boost your material's durability by leveraging EPDM-g-MAH for enhanced anti-fatigue properties in polymer blends.

- Achieve superior compatibility between polyamides and polyolefins, improving interfacial adhesion with maleic anhydride functionalized elastomer.

- Significantly enhance the toughness and durability of polyamides, making them ideal for demanding industrial applications.

- Improve mechanical properties of polymer blends by utilizing its function as a compatibilizer for polyamide and polypropylene blends.

Key Advantages Offered

Superior Impact Modification

As a premier impact modifier for polyamides, this additive dramatically improves toughness and durability, even under harsh conditions, a key benefit when improving mechanical properties plastic.

Enhanced Material Compatibility

The high maleic anhydride content ensures excellent compatibility between polar and non-polar polymers, acting as a crucial bridge for polyamide and polypropylene blends.

Extended Service Life

Experience improved anti-fatigue and aging resistance, extending the lifespan of your plastic components and reducing the need for premature replacement.

Key Applications

Polyamide Impact Modification

Significantly enhance the impact strength and toughness of PA6, PA66, and related flame retardant compounds using this effective additive.

Polymer Blend Compatibilization

Facilitate better adhesion and mechanical performance in blends of polyamides with polyolefins like polypropylene (PP) and polyethylene (PE).

Engineering Plastics Enhancement

Its ability to improve aging resistance makes it ideal for high-performance engineering plastic formulations requiring long-term durability.

Flame Retardant Compounds

Maintain crucial flame retardant properties while boosting impact resistance in advanced engineering plastic formulations.