Advanced Ceramic Honeycomb Substrates for Efficient Catalytic Oxidation and Emission Control

Leverage high-performance ceramic honeycomb for superior emission control and industrial process efficiency.

Get a Quote & SampleProduct Core Value

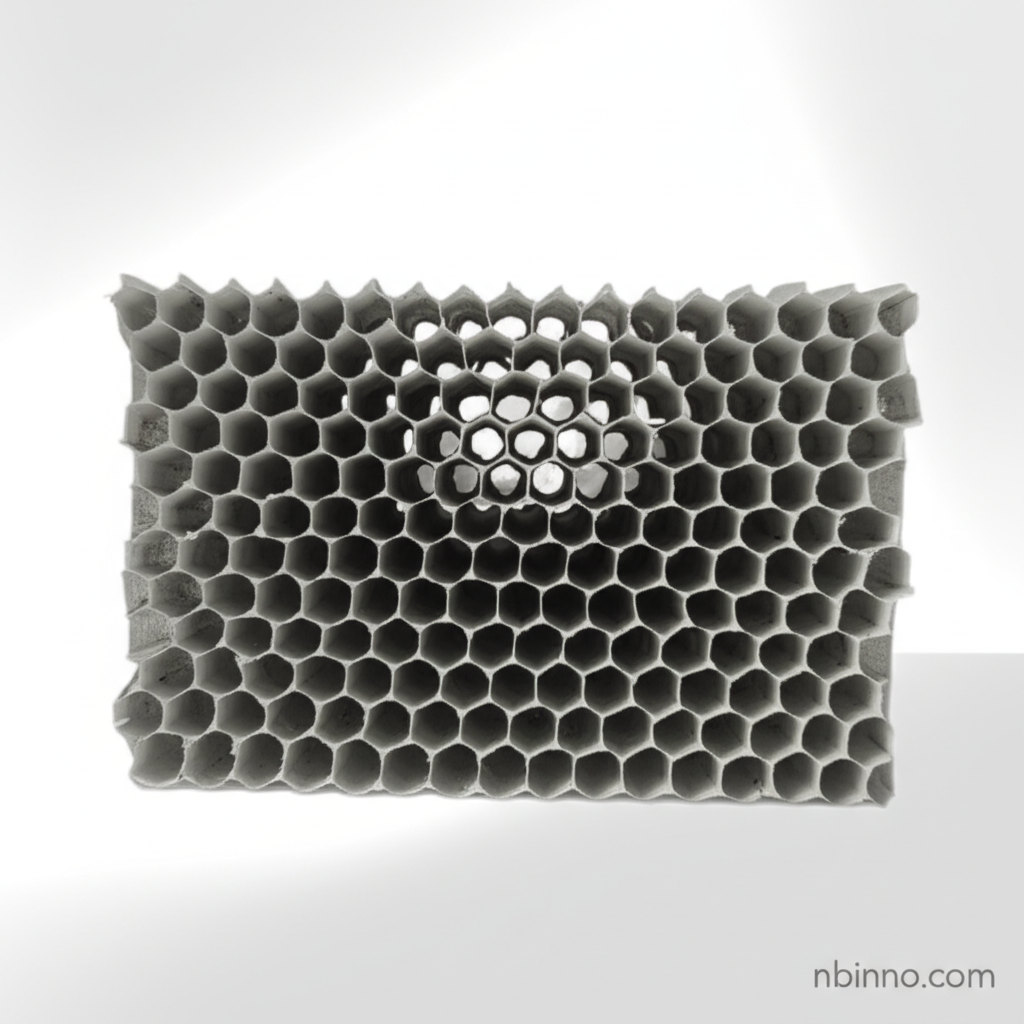

Ceramic Honeycomb Catalyst Carrier

Our ceramic honeycomb catalyst carriers are engineered to provide an exceptionally high surface area and thermal stability, making them ideal for demanding catalytic oxidation and emission control applications. They are designed to withstand extreme temperatures and chemical conditions, ensuring optimal performance in industrial processes and automotive exhaust systems.

- Utilize high-performance ceramic honeycomb for superior emission control and industrial process efficiency, a key aspect for VOC abatement.

- Experience excellent heat capacity and chemical resistance, crucial for industrial air purification applications.

- Benefit from the low pressure drop and high conversion efficiency inherent in these structures, vital for catalytic converter honeycomb substrate performance.

- Enhance your RTO systems with media that offers superior heat exchange capabilities and resistance to thermal shock, as seen in regenerative thermal oxidizer ceramic media.

Key Product Advantages

Exceptional Thermal Stability

These carriers maintain structural integrity at high temperatures, ensuring longevity in applications like industrial emission control ceramic honeycomb.

Maximized Surface Area

The intricate honeycomb design provides a vast surface area for enhanced catalytic activity, crucial for effective pollutant conversion in catalytic converter honeycomb substrate.

Low Pressure Drop Design

Facilitates smooth gas flow, minimizing back pressure and maintaining system efficiency, a significant advantage for various emission control applications.

Key Applications

Catalyst Support Systems

Serving as a robust substrate for catalytic materials, enabling efficient chemical reactions in various industrial settings, including those seeking solutions for VOC abatement.

Automotive Emission Control

Integral to catalytic converters, reducing harmful emissions from vehicles and helping meet stringent environmental standards, a core function of a catalytic converter honeycomb substrate.

Industrial Air Purification

Used in systems to purify industrial exhaust gases, removing pollutants and contributing to cleaner air quality, a common use for industrial emission control ceramic honeycomb.

Regenerative Thermal Oxidizers (RTOs)

Functions as high-efficiency heat media in RTOs, facilitating pollutant destruction while recovering thermal energy, a key role for regenerative thermal oxidizer ceramic media.