High-Quality Glass Beads for Sandblasting: Achieve Superior Surface Finishes

Experience unmatched surface preparation with our premium glass beads, engineered for precision and durability.

Get a Quote & SampleProduct Core Value

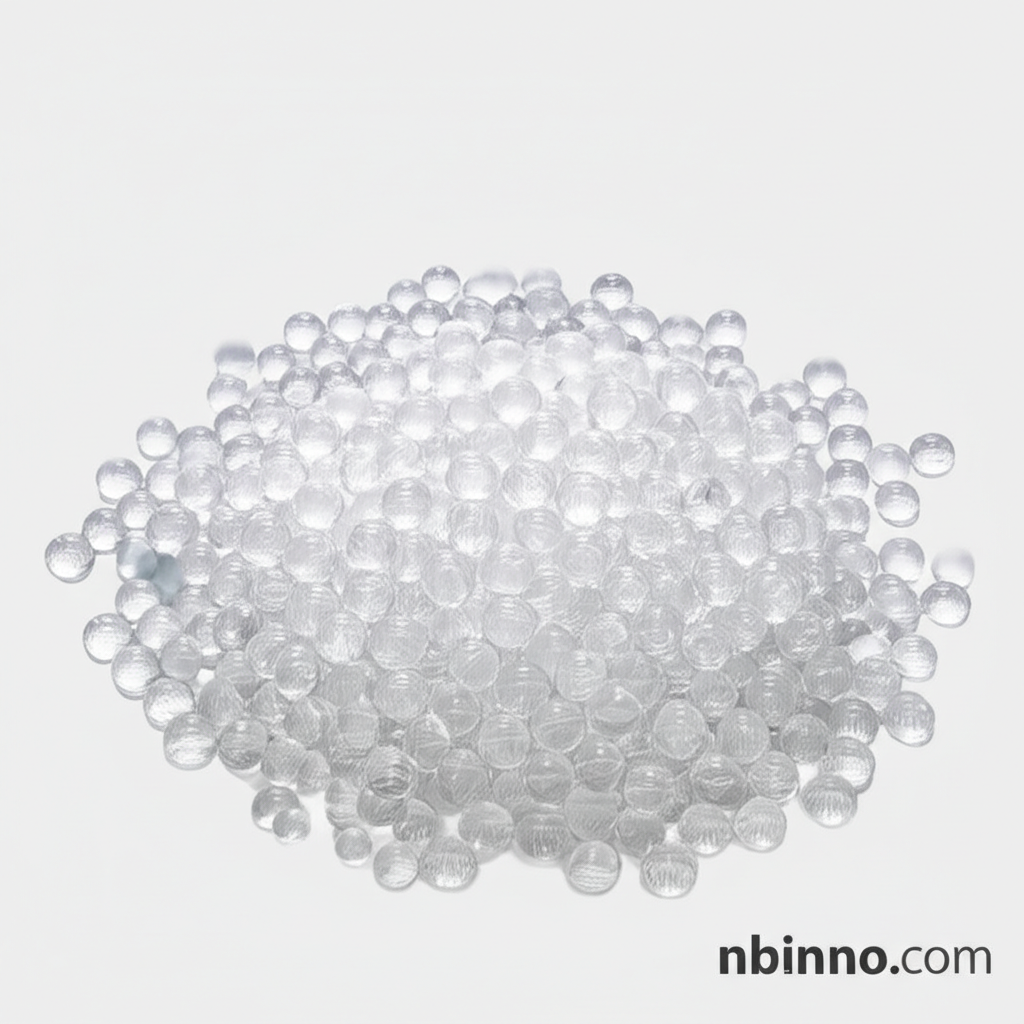

Glass Beads

Our glass beads offer exceptional chemical stability, high mechanical intensity, and a hardness of 6-7 Moh's, ensuring consistent and effective surface preparation for a wide range of industrial applications. They are designed to be reusable, making them an environmentally friendly and cost-effective choice for cleaning, peening, polishing, and deburring.

- Discover the benefits of using glass beads for sandblasting to achieve a perfect matte finish on metals.

- Learn about the various sandblasting grit size charts available to match your specific needs.

- Explore how our reusable sandblasting media can significantly reduce your operational costs and waste.

- Understand the key applications of glass beads in peening, from automotive parts to aerospace components for enhanced fatigue life.

Key Advantages

Durable and Reusable

Benefit from the exceptional durability of our glass beads, allowing for multiple cycles of use, thus reducing overall abrasive consumption and cost. This makes them a truly reusable sandblasting media for various industrial processes.

Environmentally Friendly

Our glass beads are manufactured from recycled glass and contain no free silica, making them an eco-friendly option. This contributes to a safer working environment with lower dust generation compared to traditional abrasives.

Versatile Application

With a wide range of grit sizes available, our glass beads are perfect for a variety of surface preparation tasks, including metal finishing, shot peening, cleaning molds, and deburring precision parts. They are excellent for surface preparation prior to coating.

Key Applications

Metal Surface Finishing

Achieve a clean, bright, satin finish on metal parts without dimensional changes, ideal for automotive restoration and precision components. Explore different sandblasting grit size charts to find the perfect finish.

Peening and Stress Relief

Enhance the fatigue life and stress corrosion resistance of metal components, such as aircraft engine parts and springs, through our glass beads for peening applications.

Industrial Cleaning

Effectively clean diverse moulds, remove rust and scale from automotive parts, and prepare surfaces for painting or coating, leveraging the chemical stability and mechanical intensity of our glass beads.

Glass Etching and Frosting

Create decorative effects on glass surfaces with controlled etching, a testament to the versatility of our high-quality sandblasting media.