High Purity Inert Alumina Ceramic Balls: Enhancing Efficiency in Chemical Processing

Unlock optimal performance and catalyst protection with our premium inert alumina ceramic balls.

Get a Quote & SampleProduct Core Value

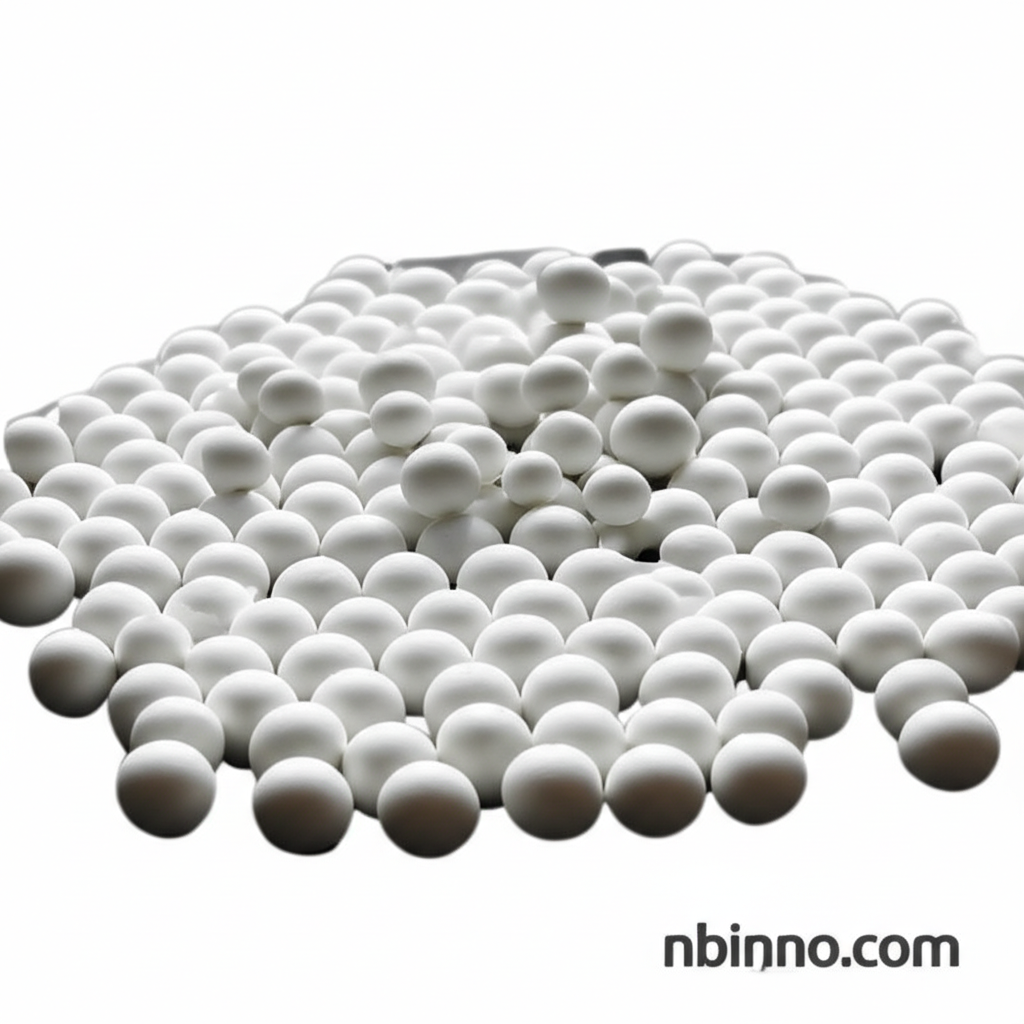

Inert Alumina Ceramic Ball

Our inert alumina ceramic balls are engineered for superior performance in demanding industrial applications. They serve as critical catalyst support media and tower packing, ensuring efficient gas and liquid distribution while protecting sensitive catalysts.

- Benefit from using high purity alumina balls catalyst support for enhanced reaction efficiency. The high alumina content (up to 99%) ensures minimal inertness and maximum effectiveness in protecting your catalysts.

- Experience excellent thermal and mechanical shock resistance, allowing these balls to withstand significant temperature fluctuations and physical stress without compromising integrity.

- Benefit from superior chemical stability, offering robust resistance to acids, alkalis, and various organic solvents, crucial for harsh chemical environments.

- Leverage these balls for efficient gas and liquid distribution, a key factor in optimizing catalytic reactions and process throughput.

Advantages Offered

Enhanced Catalyst Protection

Utilizing inert alumina ceramic balls for chemical industry applications ensures your catalysts are shielded from physical damage and chemical degradation, extending their operational lifespan.

Process Efficiency Improvement

The optimized distribution of gas and liquid, facilitated by these balls, directly contributes to higher reaction yields and improved overall process efficiency, a benefit for any petroleum refining inert ceramic ball supplier.

Durability in Extreme Conditions

With exceptional resistance to high temperatures, high pressure, and corrosive substances, these balls are ideal for the most demanding industrial settings.

Key Applications

Catalyst Support

Essential for providing a stable and protective environment for catalysts in various chemical reactors, improving reaction kinetics and catalyst longevity.

Tower Packing

Used in absorption and distillation towers to increase surface area for mass transfer, optimizing separation processes.

Heat Retention

Their material properties allow them to function effectively in heat retention applications, contributing to thermal management in industrial processes.

Gas and Liquid Distribution

Crucial for ensuring uniform flow patterns within reactors and columns, preventing channeling and maximizing contact between reactants and catalysts.