Industrial Emission Control with Advanced Honeycomb SCR Denitrification Catalysts

Achieve superior NOx reduction and cleaner emissions with our state-of-the-art SCR catalysts.

Get a Quote & SampleProduct Core Value

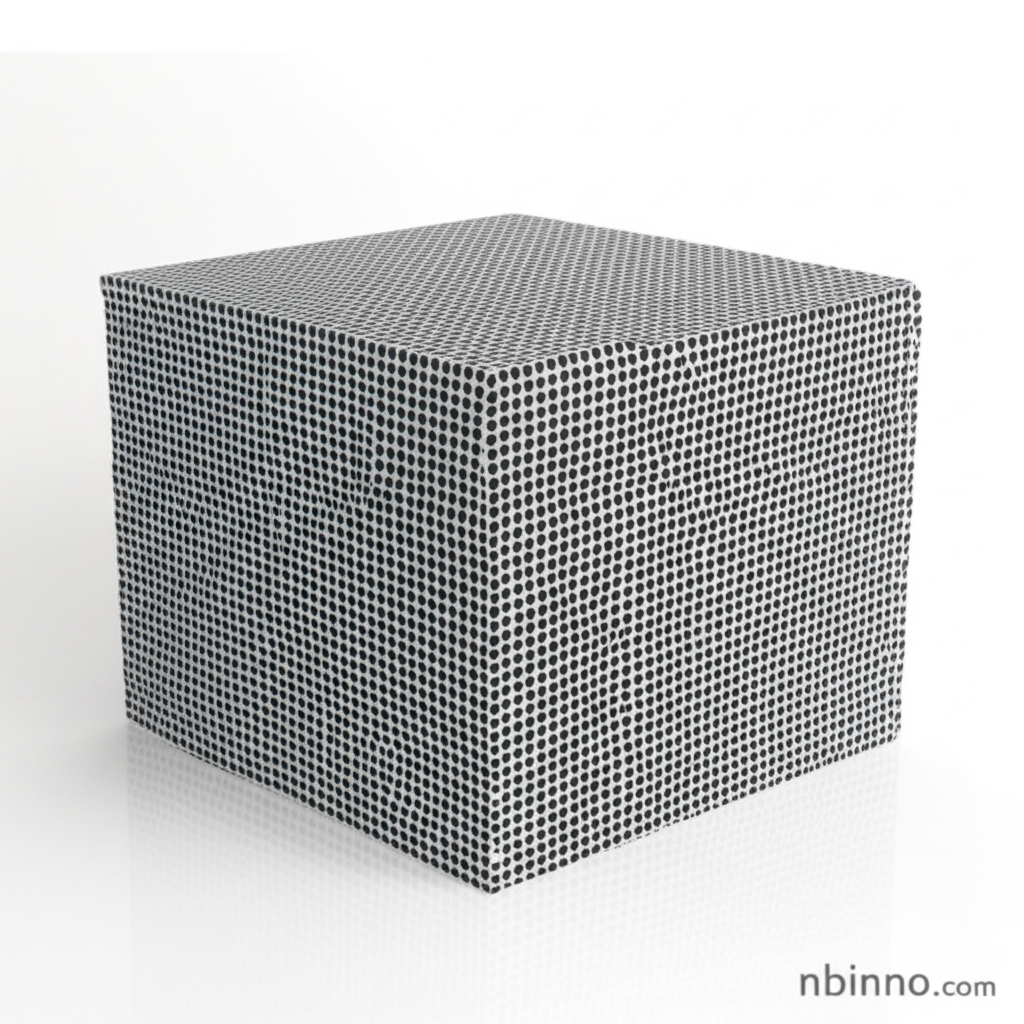

Honeycomb SCR Denitrification Catalyst

Our advanced honeycomb SCR denitrification catalysts are engineered for exceptional performance in reducing nitrogen oxides (NOx) from industrial flue gases. Utilizing a V2O5-WO3(MoO3)/TiO2 series, these catalysts ensure high activity and removal efficiency, contributing significantly to environmental protection and cleaner industrial operations.

- High activity & removal efficiency ensuring maximum NOx reduction for industrial flue gas treatment.

- Low SO2 conversion rate, minimizing secondary pollution and maintaining process integrity for emission control.

- Excellent resistance to poisoning & abrasion for sustained performance in demanding industrial environments, crucial for industrial catalyst applications.

- High durability & stability, offering a long service life of up to 24,000 hours, a key aspect of reliable SCR denitrification catalyst for industrial exhaust.

Key Advantages

Customizable Design

We offer customizable honeycomb catalyst structures, including various hole pitches, to perfectly match the specific dust concentration and pressure drop requirements of your industrial processes, aligning with customizable honeycomb catalyst for pollution control needs.

Enhanced Longevity

Our catalysts boast high durability and stability, guaranteeing a long service life of 24,000 hours, a critical factor for efficient and cost-effective denitrification catalyst manufacturer solutions.

Superior Poisoning Resistance

The formulation provides excellent resistance to poisoning and abrasion, ensuring consistent performance even in challenging industrial atmospheres, a hallmark of high-performance V2O5-WO3/TiO2 catalyst for flue gas treatment.

Key Applications

Power Plants

Effectively reduces NOx emissions from coal-fired and gas-fired power plants, supporting clean energy generation and meeting stringent environmental regulations for NOx reduction.

Waste Incineration

Treats flue gas from waste incineration facilities, minimizing atmospheric pollution and ensuring compliance with waste management standards, crucial for flue gas treatment.

Steel Plants

Improves air quality by removing NOx from steel manufacturing processes, contributing to a safer and healthier working environment and adherence to emission standards.

Petrochemical Industry

Optimizes the environmental footprint of petrochemical plants by treating exhaust gases and reducing harmful emissions, a vital aspect of modern industrial operations and a key use for SCR catalyst applications.