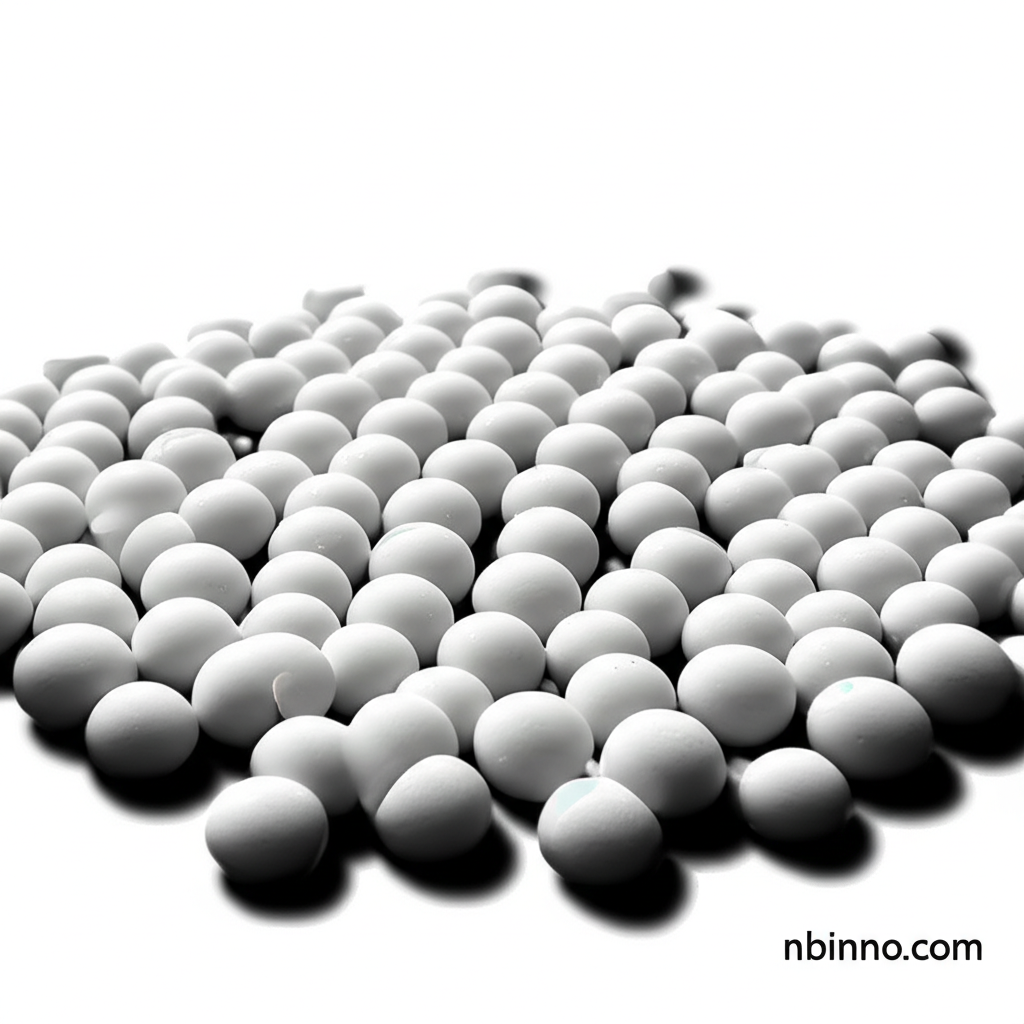

High-Purity Alumina Ceramic Balls: Inert Catalyst Support Media for Chemical Processes

Enhance your chemical processes with superior inert alumina ceramic balls, engineered for optimal catalyst support and performance.

Get a Quote & SampleProduct Core Value

Inert Alumina Ceramic Ball

Our high-purity alumina ceramic balls are engineered to serve as exceptionally stable and chemically inert support media for catalysts in a wide array of industrial applications. They are designed to withstand demanding operational conditions, ensuring the integrity and efficiency of chemical reactions.

- Leveraging inert alumina ceramic balls for catalyst support in petrochemical refineries significantly boosts process efficiency.

- The high purity alumina ceramic balls applications extend to ensuring minimal contamination in sensitive chemical manufacturing.

- Experience excellent chemical resistance ceramic balls for reactors, safeguarding your catalysts from aggressive media.

- Benefit from thermal stable alumina catalyst support media that maintains performance across a broad temperature range.

Advantages Offered by the Product

Superior Inertness

These balls are chemically inert, meaning they do not react with surrounding substances, thereby preventing unwanted side reactions and maintaining catalyst purity.

Exceptional Durability

With high mechanical strength and crush resistance, these ceramic balls can handle significant pressure and physical stress within reactor beds, prolonging their lifespan.

Wide Temperature Tolerance

Our alumina ceramic balls exhibit high thermal stability, allowing them to perform reliably in high-temperature environments common in chemical processing.

Key Applications

Catalyst Support

Acting as a robust foundation for catalysts, these balls ensure optimal surface area exposure and support, crucial for inert alumina ceramic balls for catalyst support.

Tower Packing

Used as inert packing in distillation and absorption towers to improve gas and liquid distribution, enhancing mass transfer efficiency.

Reactor Media

They serve as reliable bed media in chemical reactors, protecting catalysts and maintaining stable reaction conditions.

Adsorbent Drying

Utilized in processes requiring purification, such as drying reactive monomers in ethylene and propylene production.