High-Performance Molecular Sieves for Efficient Natural Gas Drying and Purification

Unlock optimal natural gas quality with advanced molecular sieve adsorbents for superior drying and purification.

Get a Quote & SampleProduct Core Value

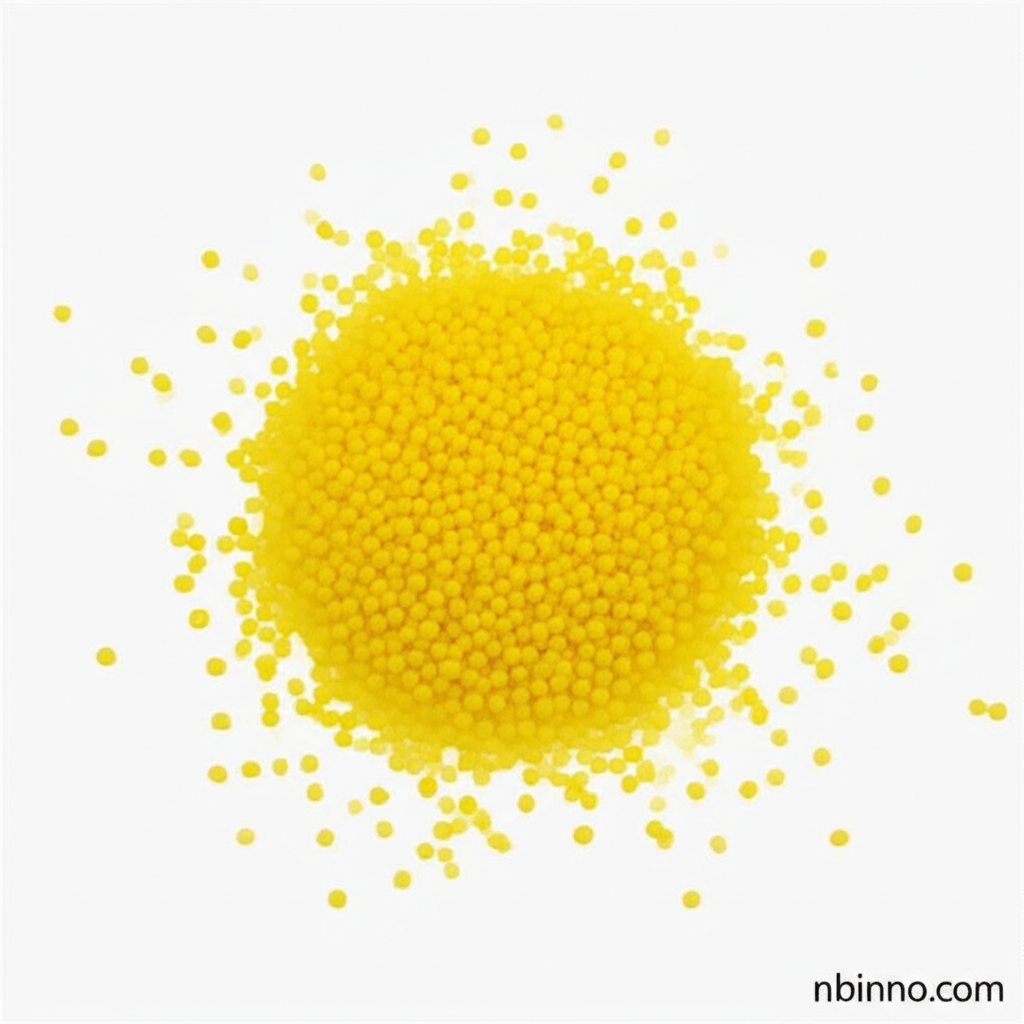

Molecular Sieve Adsorbent

Molecular sieves are critical desiccants used to remove water vapor and other impurities from natural gas streams, ensuring pipeline integrity, preventing hydrate formation, and maintaining gas quality for various industrial applications.

- Leverage the high adsorption capacity of molecular sieves for effective natural gas drying.

- Ensure gas purity and prevent corrosion with advanced molecular sieve adsorbents.

- Benefit from the reusability and cost-effectiveness of molecular sieves in gas processing.

- Utilize specific molecular sieve types (3A, 4A, 5A, 13X) for tailored natural gas purification.

Key Advantages

Superior Moisture Removal

Experience exceptional water vapor adsorption thanks to the uniform pore structure of molecular sieves, ensuring dry gas streams for critical processes.

Enhanced Process Efficiency

The high adsorption capacity and selectivity of molecular sieves for water molecules improve the overall efficiency of natural gas purification.

Long-Term Cost Savings

Molecular sieves offer significant cost benefits through their reusability and durability, reducing the need for frequent replacements and lowering operational expenditures.

Key Applications

Natural Gas Processing

Crucial for removing moisture and impurities to meet pipeline quality standards and prevent equipment damage.

Petrochemical Industries

Ensures gas purity for various chemical reactions and processes, enhancing product quality.

Air Separation

Used to maintain clean and dry air for industrial applications, protecting sensitive equipment.

Hydrogen Drying

Essential for purifying hydrogen gas for use in fuel cells and other critical applications.