Superior Foam Control for Coatings, Adhesives, and Inks

Eliminate unwanted foam to enhance product quality and manufacturing efficiency with our advanced silicone defoamer.

Get a Quote & SampleProduct Core Value

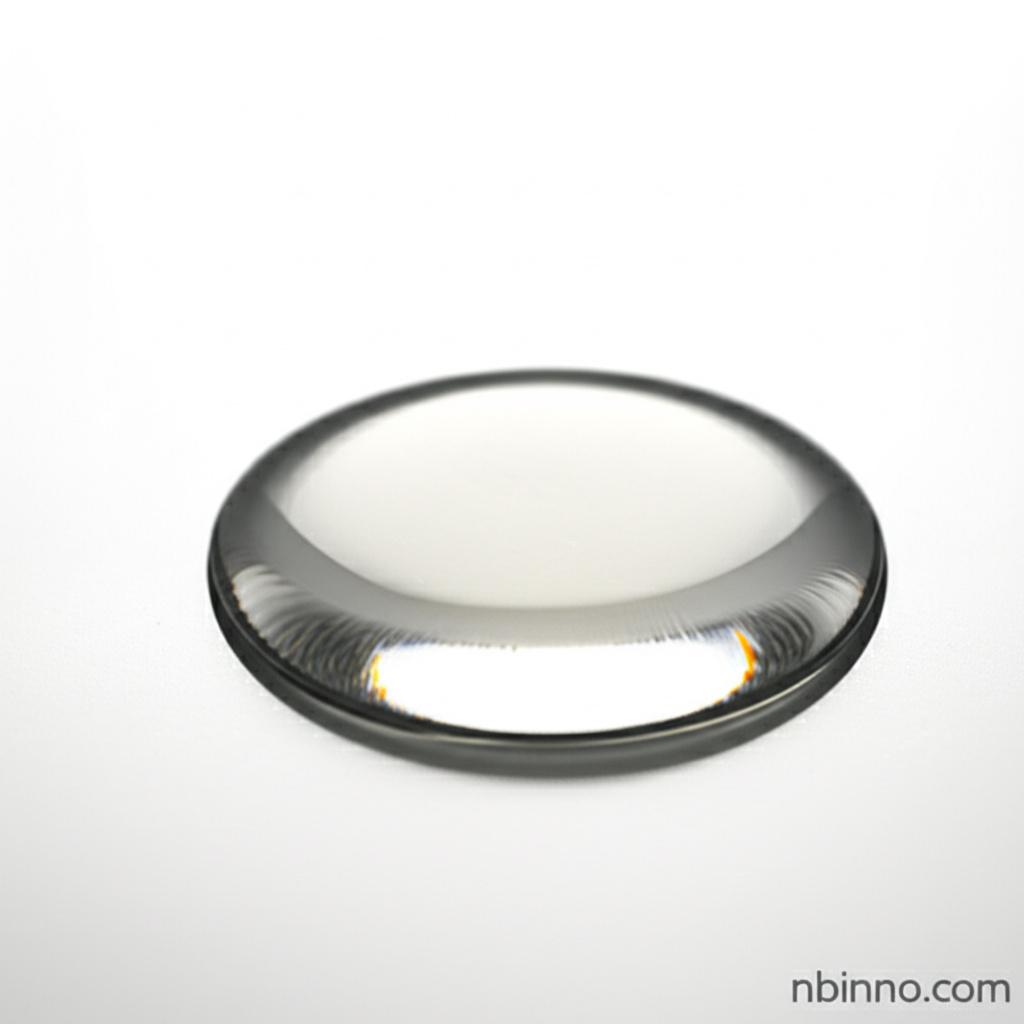

Silicone Defoamer

This high-performance silicone defoamer is expertly formulated to provide exceptional foam inhibition and elimination for a wide range of industrial applications. It is particularly effective in challenging environments such as high-viscosity and high-film thickness formulations, including solvent-free epoxy coatings and UV light curable coatings. By effectively managing bubbles produced during manufacturing and construction, it ensures a superior finished product.

- Experience excellent foam inhibition and elimination in your industrial coatings using this advanced silicone defoamer, which is crucial for achieving perfect surface finishes.

- Achieve superior surface quality in solvent-free epoxy coatings and high-viscosity formulations by preventing bubble formation during production and application processes.

- Enhance the efficiency of your manufacturing processes with our effective foam control agent, which targets bubbles generated during the production of inks and adhesives.

- Ensure optimal product properties and prevent defects in UV light curable coatings by utilizing this specialized silicone defoamer for consistent performance.

Key Advantages

Enhanced Surface Finish

Our defoamer significantly reduces surface defects caused by foam, leading to smoother, more aesthetically pleasing finishes in your coatings and inks. This is vital for meeting stringent quality standards and customer expectations.

Improved Processing Efficiency

By controlling foam formation, this additive streamlines manufacturing processes, prevents overflow issues, and reduces the need for costly rework, thus boosting overall operational efficiency and lowering production costs.

Versatile Application

The formulation is suitable for a broad spectrum of industries, including those requiring specialized solutions like high-viscosity and high-film thickness applications, making it a versatile tool for various manufacturing needs.

Key Applications

Coatings Industry

Effectively manages foam in the production and application of various coatings, ensuring a flawless surface and optimal performance.

Adhesives Manufacturing

Prevents foam-related inefficiencies during the production of industrial adhesives, ensuring consistent product quality and reliable application.

Printing Inks

Crucial for controlling foam in screen inks and other printing applications, leading to better print quality and preventing press downtime.

Specialty Formulations

Ideal for high-viscosity and high-film thickness applications, including solvent-free epoxy floors and UV curable coatings, where foam control is critical.