Unlock the Power of Molecular Sieves: Types, Applications, and Benefits

Explore the diverse world of molecular sieves, understanding their unique properties and wide-ranging industrial applications.

Get a Quote & SampleProduct Core Value

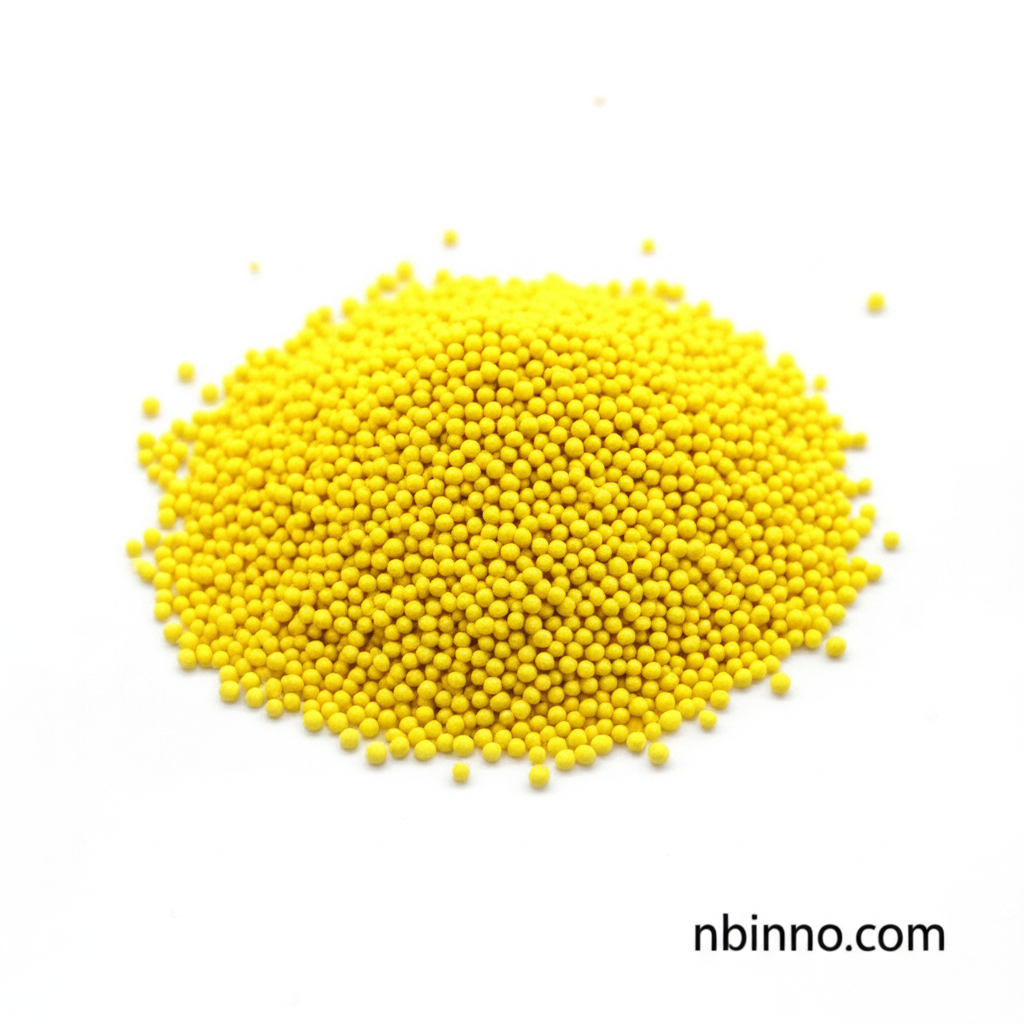

Molecular Sieve Adsorbent

Molecular sieves are highly effective crystalline aluminosilicate materials known for their unique porous structures and exceptional adsorption capabilities. Their tunable pore sizes and high surface area make them indispensable in a variety of critical industrial processes, from gas separation and dehydration to water purification and catalysis.

- Discover the diverse applications of molecular sieves, including their role in oil drilling auxiliary agents, water treatment chemicals, and rubber processing.

- Understand the chemical formulas and pore sizes of different molecular sieve types like 3A, 4A, and 5A, crucial for precise industrial applications.

- Learn how molecular sieves function as powerful desiccants and adsorbents, vital for dehydration processes in natural gas and air purification.

- Explore the catalytic properties of zeolites and molecular sieves, utilized in petrochemicals and other chemical industries for their selective reaction capabilities.

Advantages of Using Molecular Sieves

Exceptional Adsorption Capacity

Leverage the high adsorption capacity and selectivity of molecular sieves for efficient separation of gases and purification of liquids, crucial for optimizing industrial processes.

Tunable Pore Structures

Benefit from the tunable pore sizes of molecular sieves, allowing for precise separation of molecules based on size and polarity, a key factor in achieving high purity products.

Wide Range of Applications

Utilize molecular sieves across various sectors, from air drying and natural gas processing to water treatment and advanced catalysis, showcasing their versatility.

Key Applications of Molecular Sieves

Gas Separation and Purification

Molecular sieves are essential for separating gases like nitrogen and oxygen, and for dehydrating natural gas and industrial air streams, ensuring product purity and process efficiency.

Water Treatment

Their ion-exchange and adsorption properties make molecular sieves effective in removing heavy metals, ammonia, and other contaminants from water, enhancing water quality for various uses.

Catalysis

The unique pore structures and surface acidity of zeolites and molecular sieves make them excellent catalysts and catalyst carriers in petrochemical refining and chemical synthesis.

Desiccants and Drying Agents

Molecular sieves excel as desiccants, efficiently removing moisture from gases and liquids, critical for preserving product integrity in electronics, pharmaceuticals, and food industries.