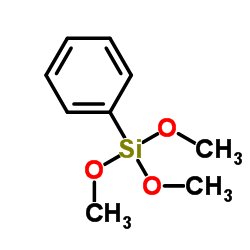

Chemical Name:Phenyltrimethoxysilane

By following our guiding principles of Samples, Quotes, Literature, and Innovation, we are able to make continual process improvements for customers.We are supplier of ingredients used in a large variety of applications. We have extensive product offerings, technical services and support, and a qualified sales team ready to deliver smart solutions for your specific needs.Has a first-class R & D team, rich experience in custom compound synthesis, good at synthesis of organic compounds such as chiral, heterocyclic, benzene rings.Our specialty chemicals are essential to technologies for consumer safety, environmental sustainability, advanced product performance and industrial process efficiency.Our company has a 2000 square meter R&D center. The company's production base is mainly located in Liaocheng City, Shandong Province, Yuncheng City, Shanxi Province.

Are you looking for China or India manufacturers of Phenyltrimethoxysilane CAS:2996-92-1, phenyl trimethylsiloxane factory or phenyl trimethoxy silane supplier? Where can buy Phenylmethoxysilane or if you want to know the price market of phenyl trimethylsiloxane? Welcome to contact us for Phenyltrimethoxysilane COA or MSDS.

CAS.NO:2996-92-1

Synonyms:Silane, trimethoxyphenyl-; Phenylmethoxysilane;

Trimethoxy(phenyl)silane; phenyl trimethylsiloxane; phenyl trimethoxy silane;

Molecular Formula:C9H14O3Si

Molecular Weight:198.29100

Physical and Chemical Properties:

Density:1.062;

Melting point:-25oC;

Boiling point:233oC;

Flash point:92oC;

Index of Refraction:1.468;

Specification:

Appearance:Colorless transparent liquid

Purity(GC):≥99.0%

Packing:200 kg/drum, can also be packaged according to customer requirements

Storage:Store in a cool, ventilated place

Application:It is used to modify the suface of inorganic fillers such as wolastonite and aluminum trihydroxide.It makes the surface of these inorganic fillers more hydrophobic and thus increases their dispersability in mineral-filled polymers.

It is especially suited for polymers that are processed at elevated temperatures.It reduces the viscosity of the polymer melt.