In the dynamic world of textile manufacturing, achieving the perfect balance of properties in finished fabrics is paramount. Consumers demand not only aesthetic appeal but also functional attributes like softness, durability, and comfort. While traditional silicone softeners excel at imparting luxurious softness and a smooth hand feel, they often present a challenge: they can significantly reduce the fabric's natural or desired hydrophilicity, making it less absorbent. This is particularly problematic for textiles such as towels, activewear, and innerwear, where water absorbency is a critical performance indicator.

To address this long-standing industry challenge, innovative chemical solutions are essential. Advanced hydrophilic silicone oil technology represents a significant step forward. Unlike conventional silicones which are inherently hydrophobic, these modified silicones are designed to maintain or even enhance the fabric's ability to absorb water, while still delivering excellent softening effects. This breakthrough allows manufacturers to produce fabrics that are simultaneously soft, comfortable, and functionally absorbent, meeting the diverse needs of the modern textile market.

The composition of these specialized products is key to their performance. Typically based on a modified block silicone oil structure, they are formulated to be highly effective as textile auxiliary agents during the finishing process. Our specific offering in this category is presented as a liquid, ensuring ease of handling and application within standard textile processing equipment. It exhibits a light yellow to transparent appearance and functions effectively within a pH range of 5.0 to 6.0. Its unique formulation ensures very weak cationic properties, contributing to excellent compatibility with other common textile auxiliaries used in complex finishing baths.

One of the remarkable features of this advanced hydrophilic silicone oil is its solubility. While the concentrated oil may require initial pH adjustment with a weak acid like HAC to a pH of 6-7 before dilution, the resulting ready-to-use emulsions are easily and readily soluble in water across any ratio. This simplifies the preparation of finishing baths and ensures uniform application onto the fabric, leading to consistent and reliable results across different production scales and methodologies.

The benefits of incorporating this hydrophilic silicone oil into textile finishing processes are manifold. Firstly, and most importantly, it imparts very good hydrophilic properties, significantly improving the water absorbency of fabrics like towels, which is crucial for their primary function. This is achieved while simultaneously providing excellent softness and a pleasant hand feel, overcoming the common trade-off with traditional softeners. Secondly, it bestows good antistatic properties, reducing static cling and making fabrics more comfortable to wear and easier to process. Furthermore, this product is non-yellowing, a critical advantage, especially when processing white or light-colored fabrics where discoloration is unacceptable. It also demonstrates very good resistance to salt and alkali, shear forces encountered during high-speed processing, and heat stability, ensuring the finished fabric maintains its desired properties through various post-processing steps and end-use conditions.

The application scope for this advanced auxiliary is broad, covering various textile types and structures. It is highly effective when applied to yarns before knitting or weaving, as well as to woven or knitted blended fabrics. Its exceptional performance on towels has been particularly noted, where the instant hydrophilicity is a key requirement. The effectiveness can be influenced by the initial preparation and capillary action of the base fabric, highlighting the importance of integrated process control in textile manufacturing.

Incorporation into textile finishing is flexible, typically employing standard methods such as padding or dipping. For the padding method, recommended dosages generally range from 20 to 50 grams per liter, applied at room temperature using one dip/one pad or two dips/two pads techniques. When using the dipping method, a dosage of 2% to 10% (on weight of fabric, o.w.f.) is usually effective, conducted at temperatures between 30 ºC and 40 ºC with a liquor ratio of 1:10 to 1:15 for approximately 30 minutes. It is strongly recommended that compatibility testing be performed prior to combining this product with other textile auxiliaries or incorporating it into existing finishing processes, allowing for necessary adjustments based on specific requirements and formulations.

In summary, the development and application of advanced hydrophilic silicone oil mark a significant advancement in textile finishing chemistry. These products enable manufacturers to achieve superior fabric softness and hand feel without sacrificing essential functional properties like water absorbency. Their excellent compatibility, non-yellowing characteristics, and robust resistance profiles make them an invaluable tool for producing high-quality textiles that meet both aesthetic and performance standards. Focusing on these innovative solutions allows textile producers to stay competitive and responsive to market demands for comfortable, functional, and durable fabrics.

For companies seeking a reliable manufacturer and supplier of high-performance textile auxiliaries, understanding the capabilities of these advanced silicone oils is crucial. Accessing detailed information regarding the price and streamlined processes for how to buy or purchase these materials is essential for optimizing production efficiency and product quality. NINGBO INNO PHARMCHEM CO.,LTD. specializes in providing such innovative chemical solutions to the global textile industry.

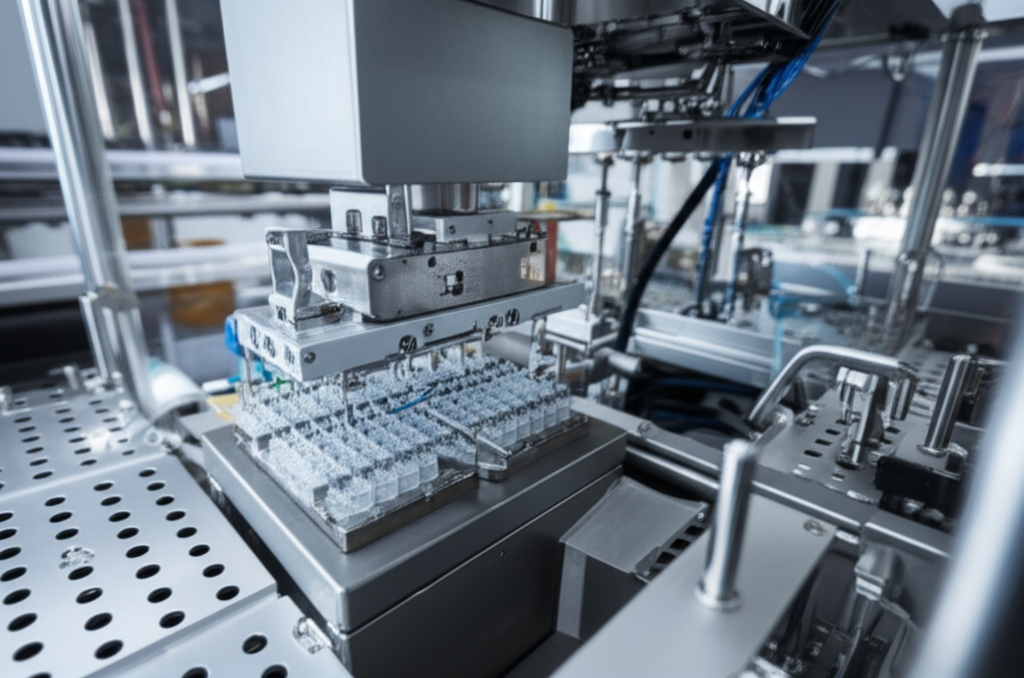

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.