Foam generation is a persistent challenge across numerous industrial sectors, including textile manufacturing, chemical processing, papermaking, and metalworking. Excessive foam not only impedes production efficiency but can also compromise product quality, lead to equipment overflow, and create unsafe working conditions. Addressing this issue effectively requires a robust and reliable antifoam solution. An Organic Liquid Silicone Defoamer stands out as a highly versatile and potent option for tackling stubborn foam problems in diverse aqueous systems.

This specialized antifoam agent is formulated as a liquid, offering ease of handling and dispersion. Unlike some traditional defoamers, it provides both rapid defoaming action, quickly collapsing existing foam, and long-lasting foam suppression, preventing its reformation. This dual functionality is critical in continuous processes where sustained foam control is essential for smooth operation. The excellent stability of this defoamer ensures that it remains effective even under varying process conditions, such as different temperatures and pH levels, making it a reliable additive in complex industrial environments.

The applications of this organic liquid silicone defoamer are broad and impactful. In the textile industry, it is invaluable during dyeing, printing, and finishing processes where detergents and auxiliaries can create significant foam. Its use helps maintain consistent product quality and streamline operations. Similarly, in the chemical and papermaking industries, where various reactions and formulations can lead to excessive foaming, this defoamer ensures process stability and prevents costly disruptions.

A particularly important area of application is in metalworking fluids and metal surface cleaning liquids. These fluids, often emulsion or water-based, are prone to foaming due to high shear forces and the presence of surfactants. Effective foam control is vital for maintaining the lubricating and cooling properties of these fluids and ensuring the quality of the finished metal surface. The organic liquid silicone defoamer, particularly variants optimized for this use, performs exceptionally well in these demanding conditions. Furthermore, its efficacy extends to other water-based systems, including applications involving acrylic emulsions and various industrial wastewater treatment processes.

Key technical characteristics contribute to its superior performance. Typically, this defoamer is nonionic, which means it is compatible with a wide range of formulations and less likely to react with other components in the system. Properties such as solid content and viscosity can be tailored or vary between specific grades to suit different application needs, impacting its dispersion properties and overall stability. While precise technical indices vary by specific type, typical pH levels are neutral, further enhancing compatibility.

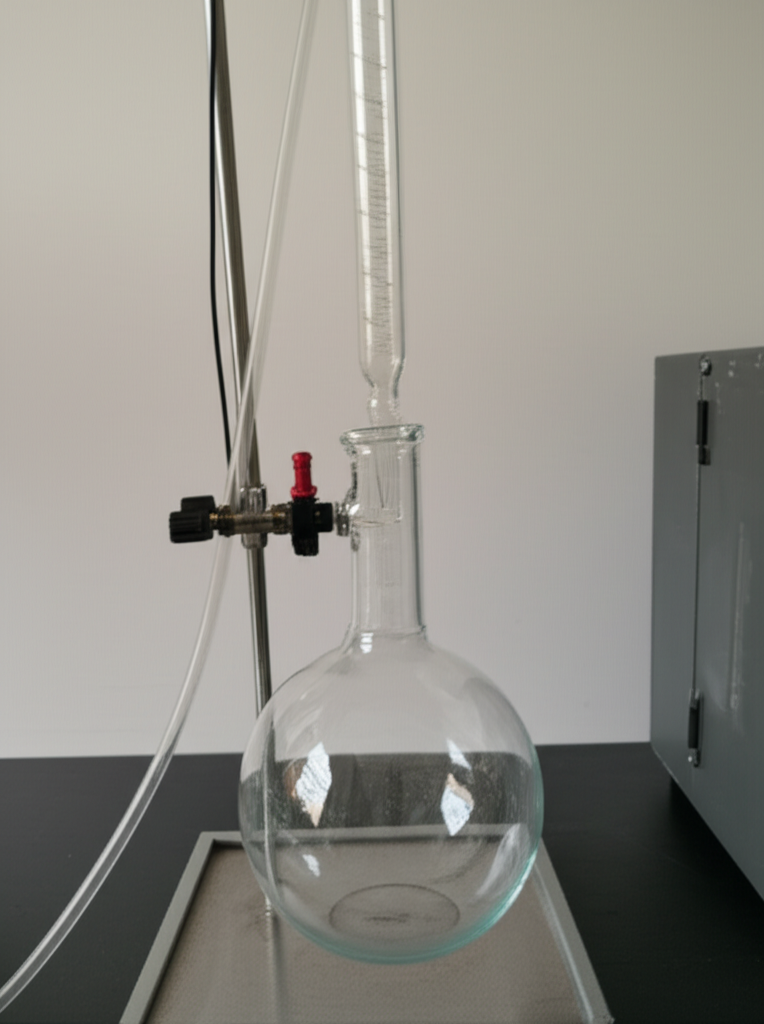

Proper usage is key to maximizing the defoamer's effectiveness. It is generally recommended to ensure uniformity by stirring before use. For optimal performance, the defoamer must be completely dispersed within the foaming medium. This can be achieved by diluting the defoamer with cold water (typically 1 to 5 times the amount) prior to adding it to the system, stirring the water slowly as the defoamer is added. Diluted solutions should ideally be used immediately. However, in systems equipped with sufficient mixing or turbulent flow that ensures uniform dispersion, the defoamer can often be added directly without prior dilution. Determining the exact appropriate concentration requires testing in the specific foaming medium, taking into account factors such as temperature, chemical characteristics, foam content, and mixing conditions. This empirical approach ensures cost-effectiveness and optimal foam control for each unique application.

Packaging and storage considerations are also important for maintaining product quality. This organic liquid silicone defoamer is commonly supplied in industrial drums, such as 25L, 50L, or 200L plastic drums, or 200L powder coating steel drums, designed for safe transport and storage. It should be stored in a cool, well-ventilated area, with temperatures ideally maintained below 25°C. Preventing freezing is crucial, as low temperatures can affect the product's stability and efficacy. Following standard guidelines for storing non-dangerous goods is generally sufficient, ensuring the product remains in excellent condition until use.

The widespread need for efficient and reliable foam control in industrial processes makes the Organic Liquid Silicone Defoamer an indispensable chemical auxiliary. Its ability to rapidly eliminate and effectively suppress foam contributes significantly to improved productivity, reduced material waste, and enhanced product quality across diverse manufacturing sectors. The demand for high-performance defoamers continues to grow as industries strive for greater efficiency and environmental compliance. Finding a trusted manufacturer and supplier is paramount for businesses relying on consistent quality and timely delivery of this essential raw material. When considering options, it is important to evaluate the product's performance characteristics, application support, and competitive price. Information on how to buy or purchase this versatile industrial chemical can be obtained by reaching out to the relevant department at NINGBO INNO PHARMCHEM CO.,LTD., a source committed to providing high-quality chemical solutions for various industrial needs.

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.