Foam formation is a persistent and often problematic phenomenon across a multitude of industrial processes. Whether in manufacturing, wastewater treatment, or chemical production, unwanted foam can significantly impede operations, leading to reduced production capacity, decreased processing efficiency, and compromising the overall quality of the final product. The presence of excessive foam can also cause equipment malfunction, overflow, and safety hazards, making its effective control a critical aspect of industrial management.

To combat these challenges, industrial defoamers are indispensable. Among the various types available, silicone defoamers stand out as a highly effective and versatile solution. These specialized chemical additives are designed to either prevent foam from forming (antifoaming) or to break down existing foam (defoaming) by disrupting the stability of the foam bubbles.

The efficacy of silicone defoamers lies in their unique chemical properties. Silicones, particularly polydimethylsiloxanes (PDMS), possess an inherently low surface tension. When introduced into a foaming system, they quickly spread across the foam lamellae – the thin liquid films surrounding air bubbles. This rapid spreading action, combined with their insolubility in most foaming media, allows the silicone particles to penetrate the foam film. Upon penetration, they create localized disruptions, causing the film to thin and eventually rupture, thereby collapsing the foam bubbles.

The applications for silicone defoamers are incredibly diverse, spanning numerous industries. In the textile printing and dyeing industry, they are crucial for preventing foam in dye baths and printing pastes, ensuring uniform coloration and print quality. They are equally vital in the production of paints and coatings, where foam can lead to surface defects like fisheyes and craters, impacting aesthetic appeal and performance. Adhesives, emulsion polymers, and inks also benefit greatly from silicone defoamers, which ensure smooth processing and defect-free products.

Beyond manufacturing, silicone defoamers play a critical role in wastewater treatment plants, where biological processes often generate significant amounts of foam that can hinder aeration and lead to operational inefficiencies. In the oil and gas industry, they are used in drilling fluids, refining processes, and natural gas sweetening to control foam. Other key sectors include pulp and paper manufacturing, metalworking fluids, and certain food processing applications, where specific food-grade silicone defoamers maintain hygiene and product quality. Their effectiveness is maintained even under high-temperature conditions, making them suitable for demanding industrial environments.

NINGBO INNO PHARMCHEM CO.,LTD. is a dedicated manufacturer and supplier of high-quality silicone defoamers. Our products are formulated to offer superior performance, providing excellent foam control with minimal dosage. They are chemically inert, ensuring they do not react with or contaminate the host system, and are known for their exceptional stability and long shelf life. We offer various grades, including highly concentrated compounds and easy-to-disperse emulsions, tailored to meet specific industrial requirements.

Choosing the right silicone defoamer can significantly enhance operational efficiency, reduce waste, and improve product quality. For detailed product information, including specific grades and application guidelines, we encourage you to connect with our technical team. To inquire about price or to buy/purchase our silicone defoamer solutions, please reach out to our sales department. We are committed to providing reliable, cost-effective foam control solutions that optimize your industrial processes.

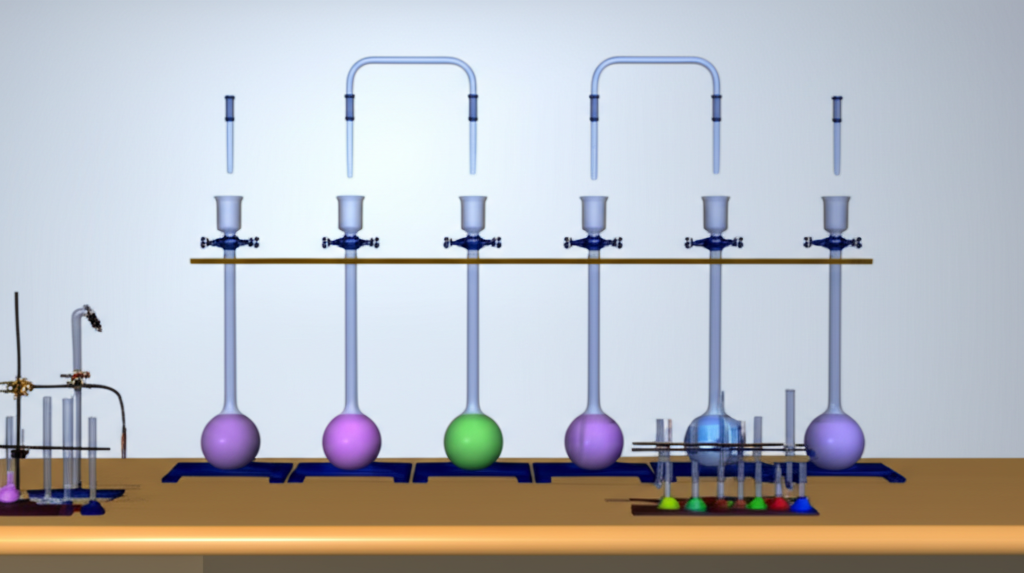

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.