In the dynamic world of textile manufacturing, achieving the perfect fabric hand feeling is paramount. Finishing agents play a crucial role in enhancing the tactile properties, appearance, and overall quality of textiles. Among these, softeners are indispensable for imparting a pleasant touch and improving drape. Non-ionic softeners, in particular, stand out for their versatility and robust performance across a wide array of fabric types, offering a modern solution for textile finishing processes.

Our Non-ionic Softener Flake 9005 is a specialized ester compound, meticulously developed to elevate the finishing of various textile materials. This premium auxiliary typically presents as a milky white to slightly yellow flake. Its non-ionic character ensures broad compatibility, and with a pH value of 4 to 5 in a diluted solution (5-10%), it maintains stability within common textile processing environments.

The core advantages of using Non-ionic Softener Flake 9005 are numerous and significant. It consistently endows fabrics with an excellent smooth, soft, and full hand feeling, which is highly sought after in consumer products. A critical benefit is its non-yellowing property, ensuring that the whiteness and color vibrancy of the treated fabric remain unaffected. This is particularly vital for light-colored or optically brightened articles. Furthermore, its good stability when mixed with both anionic and cationic agents provides flexibility in complex textile formulations, making it a reliable choice for diverse finishing requirements. This softener is also known for its ease of dilution and use, offering a good cost performance, coupled with a certain degree of hydrophilicity.

Non-ionic Softener Flake 9005 is broadly applicable to cotton, hemp, rayon, and their blends, making it a versatile addition to any textile finishing line. For preparation, the flakes can be dissolved into a 5-10% solution by adding them gradually into 70-80°C water with continuous stirring until complete dissolution. For reference, typical usage amounts include 3-8% (o.w.f) for the dipping process and 20-50g/L for the padding process, allowing for flexible application methods tailored to specific production needs.

The preference for non-ionic softeners in contemporary textile treatment stems from their inherent benefits. Unlike their ionic counterparts, non-ionic softeners do not carry an electrical charge, which means they do not interfere with dyes, brighteners, or other finishing chemicals. This ensures consistent color shades and prevents issues like staining or yellowing, especially on delicate or high-white fabrics. Moreover, these softeners are designed to maintain or minimally affect fabric absorbency and breathability, making them ideal for performance wear, towels, and medical textiles where functionality is as important as comfort.

Beyond performance, the environmental profile of non-ionic softeners aligns with the growing demand for sustainable textile practices. Many modern non-ionic formulations are biodegradable, exhibit low toxicity, and leave a minimal environmental footprint. This adherence to eco-friendly principles, often verified by relevant certifications, supports greener manufacturing processes by reducing harmful by-products in wastewater and promoting energy and resource conservation during processing. This makes them a responsible choice for manufacturers committed to sustainability.

As a reputable manufacturer and supplier, NINGBO INNO PHARMCHEM CO.,LTD. is dedicated to providing high-quality textile auxiliaries like Non-ionic Softener Flake 9005. We offer comprehensive technical support, including target sample testing and customization services, to meet the specific needs of our global partners. We pride ourselves on reliable shipment options, whether you prefer FOB or CIF terms. For inquiries regarding the price or to buy this innovative softener, please feel free to reach out. Our flexible purchase terms, including T/T, L/C at sight, DP, and C.A.D., are designed to facilitate smooth transactions, ensuring that our products are easily accessible for your manufacturing requirements. We are committed to being your trusted partner in textile chemical solutions.

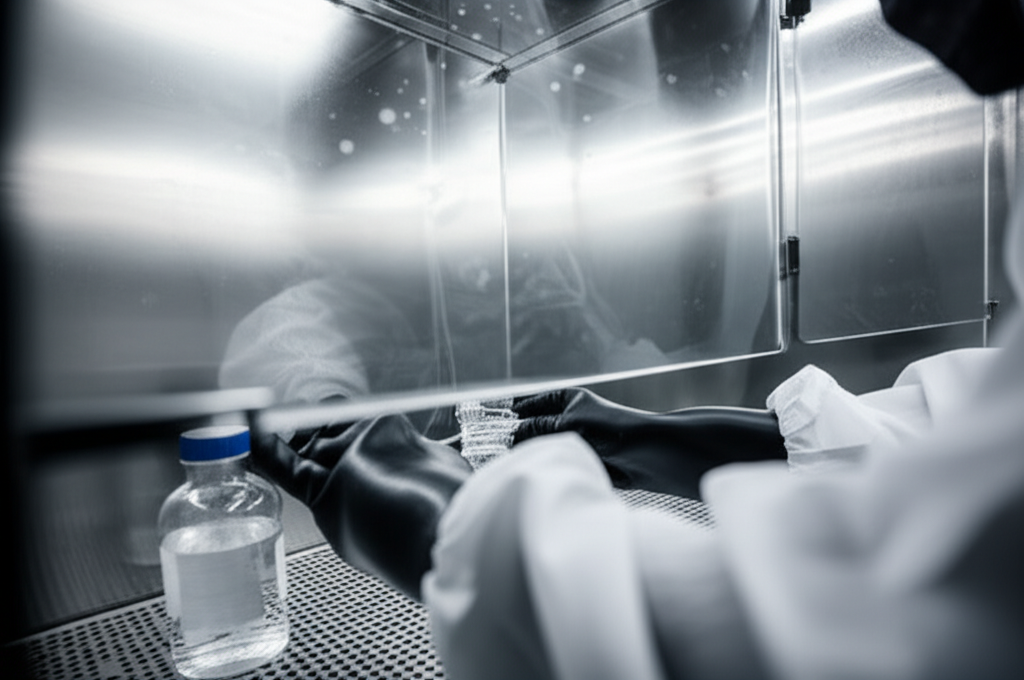

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.