In a world increasingly reliant on plastic and coated materials, ensuring their longevity and performance under various environmental conditions is paramount. One of the most significant threats to the integrity and appearance of these materials is ultraviolet (UV) radiation from sunlight. Prolonged exposure to UV light can lead to a phenomenon known as photodegradation, manifesting as discoloration, yellowing, loss of gloss, and a decline in mechanical properties. To combat this pervasive issue, specialized chemical additives known as UV absorbers are indispensable. These compounds act as a protective shield, significantly extending the lifespan and maintaining the aesthetic appeal of a vast array of products.

UV absorbers function by selectively absorbing harmful UV radiation, primarily within the 290 to 400 nanometer wavelength range, which is most damaging to polymers. Unlike UV blockers that aim to reflect light, UV absorbers work by transforming the high-energy UV light into lower, harmless forms of energy, typically dissipated as heat through rapid, non-radiative processes. This conversion occurs at a much faster rate than the degradation reactions within the polymer itself, thereby preventing the UV energy from initiating the detrimental photochemical processes that lead to material breakdown. Essentially, UV absorbers "sacrifice" themselves by preferentially absorbing the radiation, protecting the underlying substrate.

The family of UV absorbers is chemically diverse, with key classes including Benzophenones, Benzotriazoles, and Triazines. Each type offers distinct absorption characteristics and suitability for different applications. Benzophenones are versatile, often used in clear polyolefin systems, pigmented compounds, and polyesters, effectively absorbing UV light in the 300-375nm range with low volatility and minimal color impact. Benzotriazoles are highly effective for materials such as polystyrene, PVC, PMMA, PC, and ABS resins, absorbing strongly between 270-380nm and providing excellent photo permanence. More recently developed Triazine UV absorbers offer superior light stability, reduced surface migration, broad-spectrum absorption (300-380nm), and excellent dispersion, making them ideal for high-performance applications like polycarbonate and polyester, especially in transparent or light-colored materials where yellowing must be avoided.

The applications of UV absorbers span numerous industries. In the plastics sector, they are crucial for products ranging from automotive components and construction materials to agricultural films, packaging, and household items. They ensure that plastic parts retain their original color and mechanical strength even after years of outdoor exposure. For coatings and inks, UV absorbers are vital in preserving color brilliance and preventing fading and chalking on surfaces such as wood, metal, and various clear coats. They are also integral in adhesives, elastomers, and textiles, where maintaining material integrity and appearance under sunlight is critical. Their ability to integrate seamlessly into a wide range of polymeric systems, whether through surface coating or mixing into the material during formation, makes them incredibly adaptable.

While UV absorbers provide a primary line of defense, their performance can be significantly enhanced when used in conjunction with other light stabilizers, particularly Hindered Amine Light Stabilizers (HALS). This synergistic approach offers more comprehensive and long-lasting protection. UV absorbers prevent the initial absorption of UV radiation, thus reducing the formation of free radicals, while HALS act as radical scavengers, neutralizing any free radicals that might form. This dual mechanism ensures maximum protection against photodegradation and extends the material's service life even further, addressing both the initiation and propagation phases of degradation.

The effectiveness of UV protection hinges on the quality and appropriate selection of the UV absorber. Manufacturers seeking to produce durable and long-lasting plastic and coating products must prioritize sourcing high-purity and well-characterized UV absorbers. Companies like NINGBO INNO PHARMCHEM CO.,LTD. specialize in the production and supply of a comprehensive range of these essential additives, ensuring compatibility and optimal performance across diverse polymer systems. When considering UV absorber price and where to buy or purchase them, it is essential to engage with a reputable supplier or manufacturer that can provide technical support and ensure consistent product quality. Investing in superior UV absorbers is a critical step for any manufacturer aiming to enhance the weatherability and market value of their finished goods.

In conclusion, UV absorbers are fundamental components in the formulation of modern materials, providing indispensable protection against the damaging effects of ultraviolet radiation. Their diverse chemical structures and mechanisms of action allow for tailored solutions to specific application requirements, ensuring that products retain their integrity, functionality, and aesthetic appeal for extended periods.

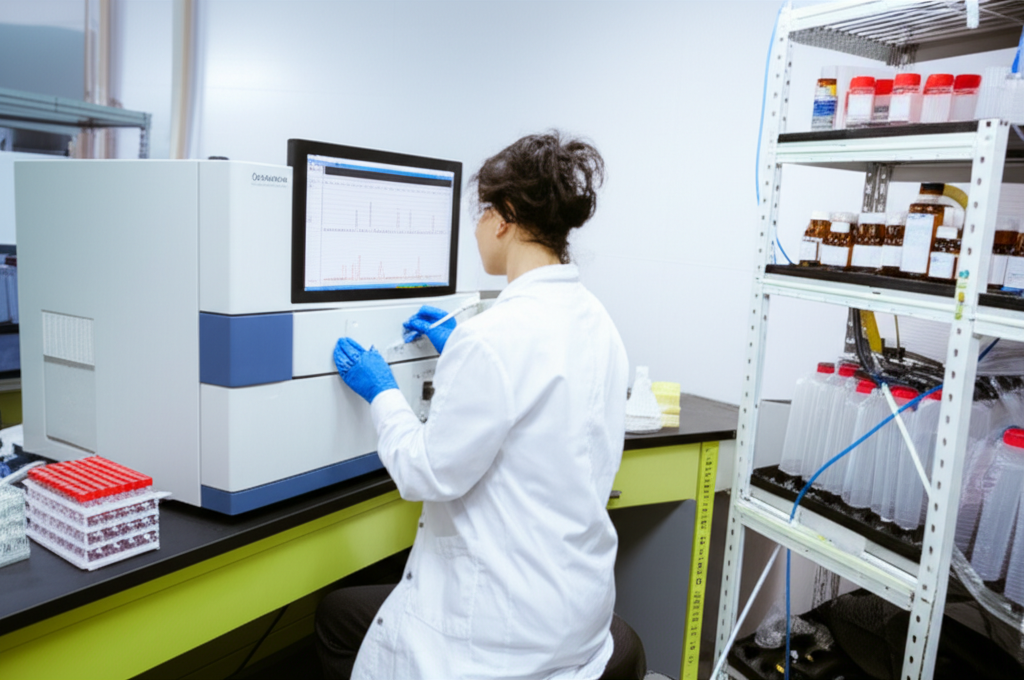

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.