Hydroxypropyl Methyl Cellulose (HPMC), also known by the abbreviation MHPC or the chemical name Hypromellose, stands as a cornerstone in modern industrial applications, particularly within the construction and chemical sectors. As a non-ionic cellulose ether derived from refined cotton, HPMC is a versatile polymer offered in a readily usable powder form. Its synthesis involves specific etherification under alkaline conditions, resulting in a white or whitish powder that is safe, non-toxic, and environmentally biodegradable.

One of the most critical properties of HPMC is its exceptional water retention capability. In applications like cement-based mortars and gypsum plasters, this property is vital. It ensures that the mixture maintains adequate moisture levels for a prolonged period, allowing for proper hydration of the cement or gypsum and extending the open time for application. This significantly helps in mitigating common issues such as rapid drying, cracking, and poor bonding, which can compromise the structural integrity and finish quality of building materials.

Beyond water retention, HPMC serves as an effective thickener. This thickening effect is crucial for modifying the rheology of wet mixtures. In mortars and coatings, it provides excellent consistency and workability, making the materials easier to apply and spread. Increased viscosity helps prevent the material from sagging or dripping on vertical surfaces, a particularly important benefit in applications like wall plasters, tile adhesives, and skim coats. The ability to control viscosity across a wide range (from low to high) allows for tailored HPMC grades suitable for specific performance requirements.

Adhesion is another key performance characteristic enhanced by HPMC. By improving the plasticity and consistency of mortar, HPMC helps it bond more effectively to the substrate. This improved bonding strength is essential in applications such as tile adhesives, where a strong, durable connection between the tile and the underlying surface is paramount. For external wall insulation systems (EIFS), enhanced adhesion ensures that insulation boards remain securely attached to the building facade, contributing to the system's long-term performance and safety.

HPMC also contributes to the overall operationality and efficiency of construction projects. Its improved lubricity and plasticity make mortars and plasters smoother and easier to handle, reducing the physical effort required for application and potentially speeding up the construction process. For self-leveling mortars, low-viscosity HPMC grades can maintain fluidity while providing necessary water retention, preventing segregation and ensuring a smooth, even surface finish.

The versatility of HPMC extends across numerous industries. While profoundly impactful in construction for applications like wall putty, tile adhesive, cement mortar, dry mix mortar, wall plaster, skim coat, concrete admixtures, and joint fillers, it is also widely utilized in coatings, paints, detergents, synthetic resins, ceramics, textiles, and oil fields. In paints and coatings, HPMC acts as a thickener, stabilizer, and suspension agent, ensuring consistent pigment distribution and proper film formation. In daily chemicals like detergents and shampoos, it provides viscosity control and stability.

Technically, HPMC is characterized by parameters such as viscosity, purity (typically around 99%), and particle size (e.g., passing 80-100 mesh). Different applications require specific viscosity grades to achieve optimal performance. The careful selection of HPMC grade based on factors like the desired rheology, water retention, and application method is critical for formulating high-performance end products. The manufacturing process, utilizing refined cotton as the raw material, ensures a product with consistent quality and properties.

Safety and environmental considerations are increasingly important in material selection. HPMC's biodegradable nature and non-toxic profile make it a responsible choice for a wide array of applications, aligning with global efforts towards sustainable building materials and chemical products.

Understanding the specific needs of various applications, from improving the anti-sagging properties of thick-coat plasters to ensuring the stability of underwater concrete or preventing segregation in self-compacting mixes, allows for the optimal utilization of HPMC's diverse benefits.

When sourcing this essential additive, partnering with a knowledgeable and reliable manufacturer and supplier is paramount. Factors such as product consistency, technical support, customized solutions, and a competitive price are key considerations for businesses looking to optimize their formulations and production processes. To buy or purchase Hydroxypropyl Methyl Cellulose (HPMC) that meets rigorous quality standards for various industrial applications, exploring options directly from a specialized manufacturer ensures access to diverse grades and technical expertise necessary for achieving desired product performance and cost efficiency.

NINGBO INNO PHARMCHEM CO.,LTD.

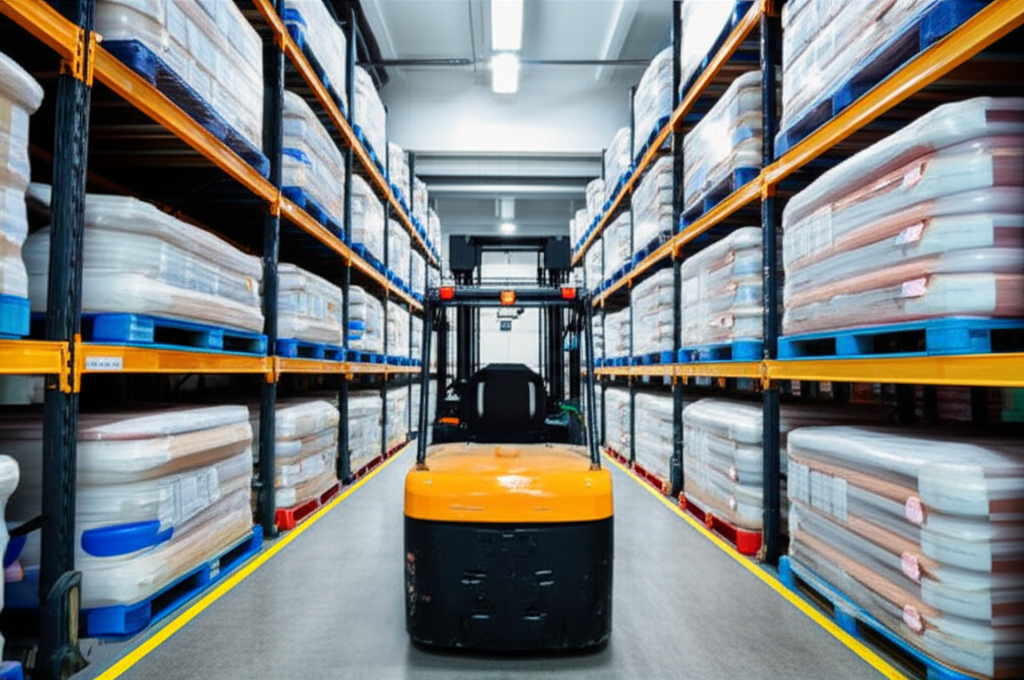

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.