Fatty Alcohol Polyoxyethylene Ether, widely recognized by the acronym AEO and identified by the CAS number 68439-50-9, represents a critical class of non-ionic surfactants essential to numerous industrial applications. As a versatile raw material, AEO is extensively utilized in formulating products for household, industrial, and personal care sectors. Its structure, comprising a lipophilic fatty alcohol and a hydrophilic polyoxyethylene chain, provides a balance of oil and water solubility, making it an effective emulsifier, dispersant, wetting agent, and foaming agent. Different grades of AEO, characterized by varying degrees of ethoxylation, such as AEO-7 and AEO-9 mentioned in the source material, offer tailored properties to meet diverse formulation needs and performance requirements in the final product.

The application of Fatty Alcohol Polyoxyethylene Ether as a detergent material is one of its most significant uses. Its powerful emulsifying and grease-cutting abilities make it indispensable in the production of high-performance laundry detergents, dishwashing liquids, hard surface cleaners, and industrial degreasers. AEO excels at reducing surface tension, allowing cleaning solutions to penetrate and lift dirt effectively. Furthermore, its non-ionic nature means it is compatible with a wide range of other surfactants, builders, and additives commonly found in cleaning formulations, enhancing overall cleaning efficiency and stability across various water temperatures and hardness levels. This compatibility contributes to the formulation of stable and effective cleaning products.

In the personal care industry, Fatty Alcohol Polyoxyethylene Ether functions primarily as a gentle yet effective cleansing agent and emulsifier. It is a common ingredient in shampoos, body washes, facial cleansers, and liquid soaps, providing excellent foaming properties and helping to remove dirt and oils from skin and hair without causing excessive dryness or irritation compared to some other surfactant types. Its emulsifying power is also valuable in lotions and creams, helping to blend oil and water phases for stable and aesthetically pleasing product textures. The quality specifications, such as appearance (colorless to slightly yellowish liquid), hydroxyl value, pH, and low moisture content, are crucial for ensuring the safety and performance of cosmetic formulations, meeting stringent industry standards.

Beyond detergents and personal care, Fatty Alcohol Polyoxyethylene Ether finds applications in the textile industry as a wetting agent and scouring agent, in the paper industry as a deinking and wetting agent, and in agriculture as an emulsifier in pesticide formulations. Its robust performance across a broad spectrum of uses highlights its importance as a fundamental chemical building block. The specific grade of AEO selected is critical; for example, AEO-7 with fewer ethoxy units tends to be more oil-soluble and a better emulsifier for non-polar substances, while AEO-9, being more water-soluble, is often preferred for aqueous systems and foaming applications. Careful consideration of these properties is vital for optimizing product performance and ensuring efficacy.

For businesses requiring reliable sourcing of Fatty Alcohol Polyoxyethylene Ether (AEO, CAS 68439-50-9), partnering with a trustworthy manufacturer and supplier is essential to guarantee consistent quality and supply chain reliability. Obtaining competitive price quotations and terms is a key factor in procurement strategy. To efficiently buy or purchase high-purity AEO, engaging with experienced chemical producers ensures access to detailed product specifications and technical support. Securing a stable supply of this vital raw material from a reputable source provides a significant advantage in producing high-quality detergent and cosmetic products that meet market demands and regulatory standards.

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

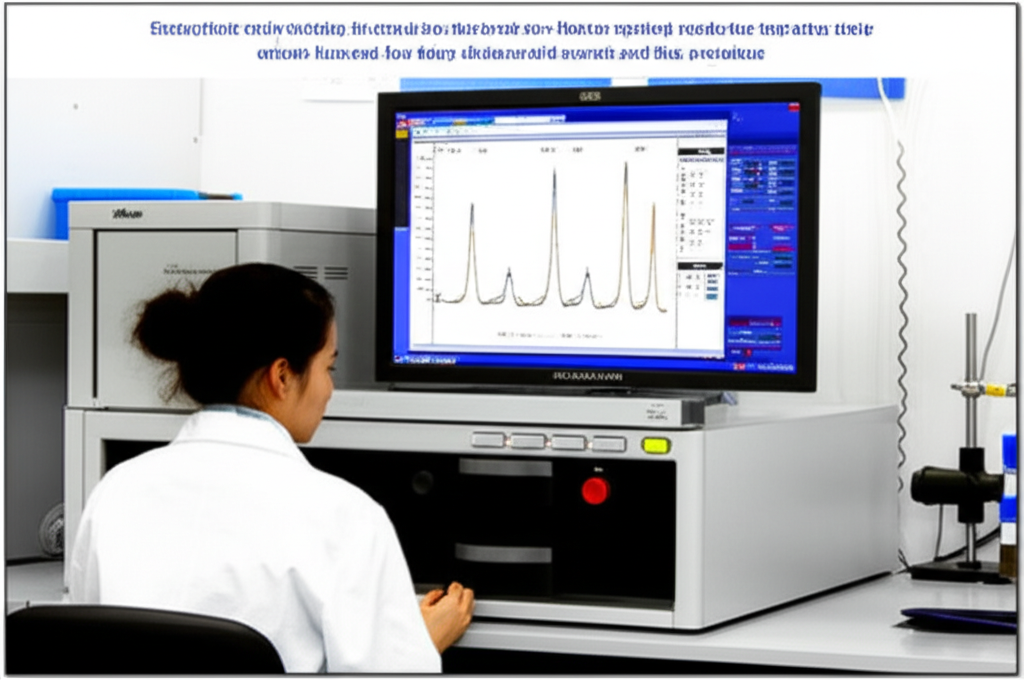

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.