3,4-Dichlorobenzotrifluoride (DCBTF), a pivotal chemical intermediate in agrochemical synthesis, sees transformative innovation through a newly developed sustainable manufacturing approach. Traditionally utilized in herbicides like lactofen and insecticides such as fipronil, DCBTF's importance stems from its fluorine-enhanced reactivity. However, conventional production methods, such as the multi-step toluene chlorination route or direct chlorination techniques, face critical limitations including high operational complexity, elevated costs, substantial waste generation, and undesired isomer formation, which compromise yield and environmental safety.

The breakthrough process addresses these challenges by leveraging 3,4-dichlorotoluene—a cost-effective byproduct from 2,4-dichlorotoluene manufacturing—as its primary feedstock. This strategic pivot not only resolves industrial waste accumulation issues but also streamlines synthesis to just two stages: chlorination and fluorination. In the initial phase, feedstock undergoes catalytic chlorination at 115-125°C for 20-24 hours using a copper chloride-copper powder catalyst mixture (mass ratio 1:1). Careful control ensures chlorine gas flow rates between 40-80 m³/hour, with reaction completion confirmed when dichloro-dichlorotoluene impurities fall below 0.5%. Subsequent purging with dry air eliminates residual gases, yielding pure 3,4-dichlorotrichlorotoluene intermediate.

Fluorination follows with anhydrous hydrogen fluoride (HF) at a 3-3.5:1 molar ratio under 110-115°C and 1.5-2.5MPa pressure. This 4-10 hour reaction involves precise steam-heat management via reactor jackets, with pressure-regulated venting. Target compound formation (>98% DCBTF) triggers depressurization and air stripping to remove HF residues. The crude product is then distilled under atmospheric conditions at a 5:2–3:1 reflux ratio, collecting fractions vaporizing between 172-175°C to achieve >99% purity. Final neutralization with sodium carbonate ensures pH stabilization before packaging.

Operational data from scale-up trials validate exceptional efficiency: Bench-scale batches produced DCBTF at 99.1-99.5% purity, while 3000-liter reactor runs yielded 99.3% pure output. Unlike legacy methods—which generate problematic isomers like 2,4-dichlorobenzotrifluoride—this route eliminates side-product contamination entirely. Crucially, it slashes reaction steps versus traditional processes, reducing chlorination stages by one. This innovation significantly cuts hydrochloric acid and hypochlorite waste volumes while lowering energy consumption.

Economically, repurposing discounted byproduct feedstocks drives down raw material expenses by approximately 40%, transforming inventory liabilities into profit streams. Environmentally, the technique minimizes emissions through closed-loop gas recovery systems, aligning with circular economy principles. Its scalability supports high-volume herbicide manufacturing—particularly relevant as global demand for fluorinated crop-protection agents grows 6% annually. Industry experts note this method could be adapted for similar intermediates, heralding a broader shift toward low-waste chemical engineering in fine chemical sectors.

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

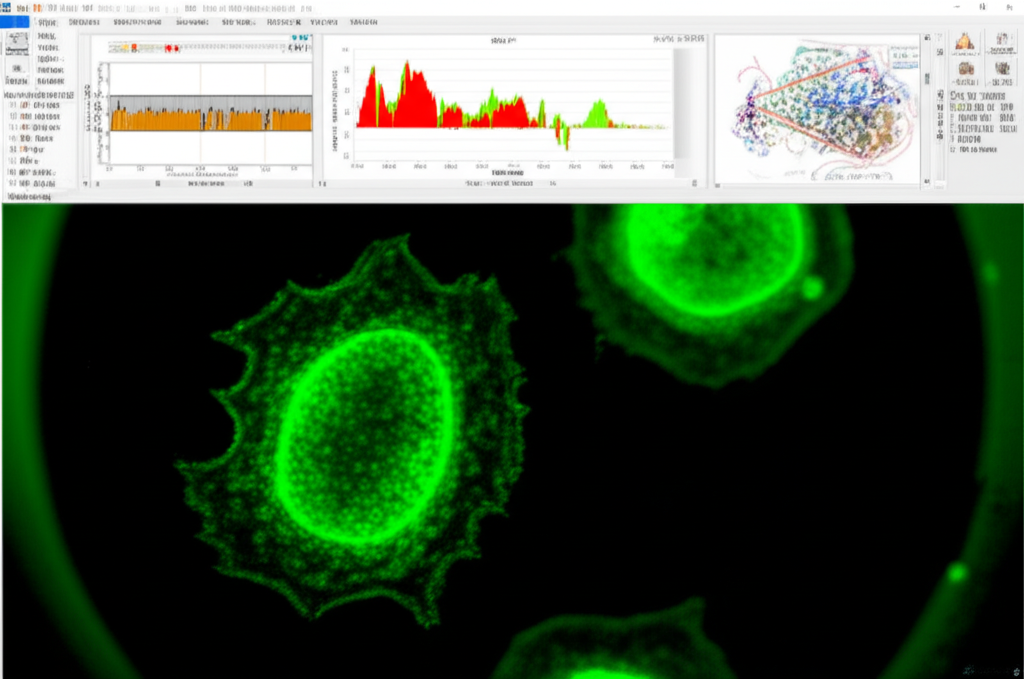

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.