A significant breakthrough in the industrial synthesis of 2,4,6-trimethylbenzoic acid (TMBA), a crucial intermediate for dyes, insecticides, pharmaceuticals, and photoinitiators like trimethylbenzoyl chloride and polymeric photoinitiators, has been achieved. Traditional production methods, plagued by difficult separation, severe equipment corrosion from acid gases, low yields, reliance on hazardous agents like chlorine gas, and challenges using powdered iron oxide catalysts leading to significant iron contamination, present substantial technical and environmental hurdles.

The novel process overcomes these limitations through a streamlined reaction sequence: Friedel-Crafts acylation, chloroform reaction, and hydrolysis. Crucially, it employs industrial-grade reagents: mesitylene (a C9 fraction refinery byproduct) and chloroacetyl chloride. The reaction replaces problematic catalysts like corrosive AlCl3 or contaminating Fe2O3 powder with a specifically designed supported iron oxide catalyst. This catalyst is prepared by impregnating carriers like zeolites (Na-type, H-type, X-type, Y-type, β-type, A-type, or mixtures) or metal oxides (Al2O3, MgO, TiO2) with aqueous solutions containing iron, nickel, or cobalt salts, followed by drying (60-150°C, 3-8h) and calcination at 300-700°C for 4-12 hours. Applied at only 1-10‰ relative to mesitylene weight, this reusable catalyst enables near-quantitative mesitylene conversion (>97%) and superb selectivity (>98%) during the acylation stage at 60-90°C.

The second key innovation lies in the chloroform reaction. By utilizing sodium hypochlorite (10-20% concentration) instead of highly polluting chlorine gas as the oxidizing agent, and employing phase-transfer catalysts (Benzyltrimethylammonium bromide or Tetrabutylammonium bromide), this stage achieves remarkable efficiency under milder (around 55°C) and safer conditions. The stoichiometric balance typically sets TMBA precursor : Sodium Hypochlorite : Caustic Soda at 1 : 8-15 : 0.8-2 mol ratio.

In the final stage, the reaction mixture undergoes extraction, phase separation, acidification, and recrystallization, yielding high-purity TMBA. Laboratory tests demonstrate conversion rates consistently exceeding 95% with end-product purity above 91%. The environmental benefits are pronounced: eliminating corrosion-inducing fumes and hazardous chlorine gas, along with preventing iron contamination through the heterogeneous catalyst, allows for safer, cleaner industrial operation.

Economically, the method gains advantage by utilizing cost-effective, industrial-grade starting materials and recovering excess chloroacetyl chloride. The catalyst's reusability and the efficient, continuous-operations-friendly nature of the supported catalyst system significantly contribute to reduced production costs. This combination of high efficiency, enhanced environmental compatibility, material economy, and operational simplicity renders this new synthetic route highly suitable for large-scale industrial implementation of 2,4,6-trimethylbenzoic acid manufacture.

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

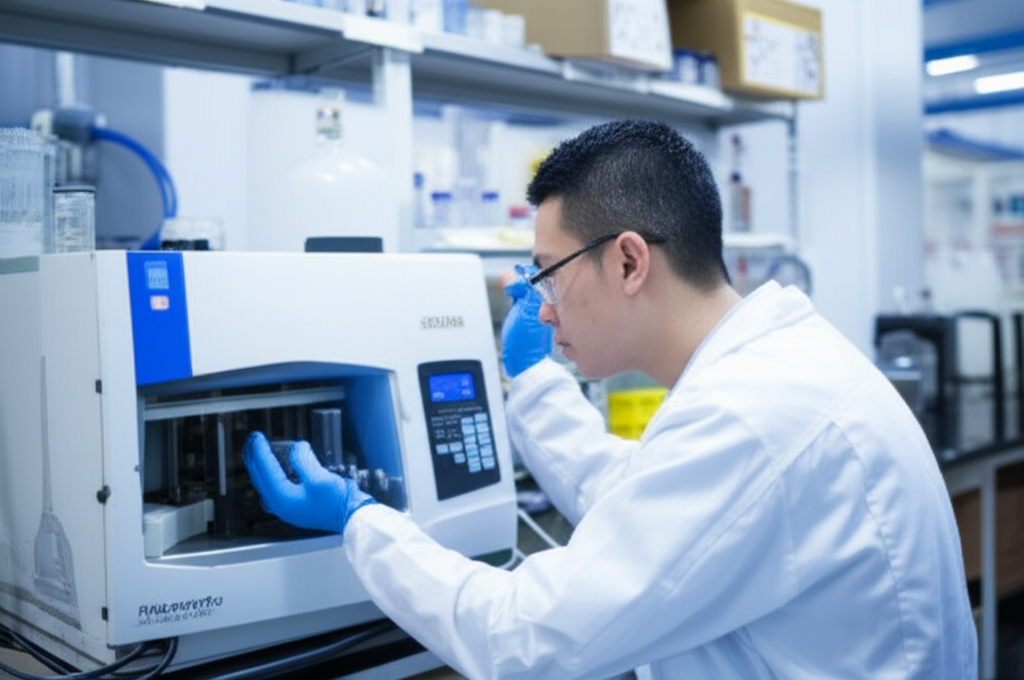

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.