Aluminium Sulphate, with the chemical formula Alu2082(SOu2084)u2083, stands as a fundamental and indispensable inorganic salt widely utilized across numerous industrial sectors. Often recognized for its role in water purification, it is a highly versatile chemical reagent distinct from alum, although frequently associated with similar applications. This compound presents itself typically as white flakes, granules, or a fine powder, exhibiting an acidic nature when dissolved in water.

One of the most critical applications of Aluminium Sulphate is its function as a **flocculant** and **coagulant** in water treatment processes. It is extensively employed in both the purification of drinking water and the treatment of municipal and industrial wastewater. The mechanism involves introducing Aluminium Sulphate into raw water, where it rapidly hydrolyzes to form positively charged aluminum hydroxide precipitates. These precipitates neutralize the negative charges of suspended particles, such as clay, silt, organic matter, and microorganisms, causing them to aggregate into larger, heavier masses called flocs. These flocs are then easily removed through sedimentation or filtration, significantly reducing turbidity, color, and suspended solids, thereby producing cleaner and safer water. The non-ferric grade, characterized by a very low iron content, is particularly crucial for potable water treatment to avoid staining and maintain high purity.

Beyond its pivotal role in water purification, Aluminium Sulphate is a cornerstone in the **paper industry**. Here, it serves primarily as a sizing agent, enhancing the water resistance and reducing the absorbency of paper. This is achieved by precipitating rosin size onto the cellulose fibers. It also plays a role in pH control and retention of fillers and pigments, contributing to the overall quality and characteristics of the finished paper product. Its effectiveness in this application has made it a long-standing chemical auxiliary in papermaking processes worldwide.

The utility of Aluminium Sulphate extends into a myriad of other industrial applications, showcasing its remarkable versatility. In the dye industry, it acts as a mordant, helping dyes adhere more firmly to textile fibers. It is used as a precipitant in the production of various pigments. In the construction sector, it can be an accelerator for concrete setting. It finds application in agriculture to adjust soil pH. The cosmetic industry utilizes it as an astringent agent in antiperspirant formulations due to its ability to constrict pores. Furthermore, it is employed in fire extinguishing foams, leather tanning, wood preservation, and as a stabilizer in food processing, particularly for albumin products. Each application leverages specific chemical properties of Aluminium Sulphate, whether it's its acidity, its ability to form precipitates, or its reactivity with other substances.

Maintaining **high quality** and consistent specifications is paramount for Aluminium Sulphate, especially when used in sensitive applications like drinking water treatment. Key quality parameters include the minimum percentage of Aluminium Oxide (Alu2082Ou2083), which indicates the product's strength, and the maximum limits for impurities such as iron, insoluble matter, and heavy metals like lead and arsenic. Different grades are available to meet the specific requirements of various industries, with stringent standards applied to drinking water grade material to ensure safety and efficacy. Reliable suppliers adhere to international quality certifications and testing protocols to guarantee product purity and performance.

Packaging and logistics are crucial considerations for the global supply of Aluminium Sulphate. It is commonly available in various package sizes, including 25kg and 50kg polypropylene woven bags, as well as 1000kg bulk bags (Jumbo bags), to accommodate different handling and usage scales. Efficient transport in standard containers, often allowing for significant volumes like 28 metric tons per container, facilitates cost-effective delivery to customers across continents. Secure packaging ensures the product's integrity during transit and storage, protecting it from moisture and contamination.

The production of Aluminium Sulphate typically involves reacting aluminum hydroxide or clay minerals with sulfuric acid under controlled conditions. The specific process parameters are carefully managed to achieve the desired product purity and physical form (flakes, granules, or powder). Continuous process improvement and quality control measures throughout manufacturing are essential to ensure batch-to-batch consistency and meet the demanding specifications required by end-users in critical applications like water treatment and papermaking. Environmental considerations are also increasingly important, with focus on sustainable production methods and waste minimization.

Sourcing this essential chemical requires partnering with experienced and reliable suppliers who can ensure not only product quality but also consistent availability and efficient logistics. Understanding the specific requirements of your application – whether it's the need for a low-iron, high-purity grade for drinking water or a standard industrial grade – is key to selecting the appropriate product. Considerations such as minimum order quantities, lead times for delivery, and payment terms are all part of the procurement process.

For those seeking a dependable **manufacturer** and **supplier** of high-quality Aluminium Sulphate, navigating the global market requires expertise. Factors influencing the **price** can include production costs, transportation, packaging, and fluctuating raw material markets. When looking to **buy** or **purchase** Aluminium Sulphate in bulk, researching reputable sources that offer transparent pricing structures and guarantee product specifications is vital for operational efficiency and product performance. Reliable suppliers are equipped to handle complex logistics and provide technical support to ensure smooth transactions and successful application outcomes, meeting the needs of various industrial clients globally. The ability to provide flexible quantities and tailored delivery solutions further enhances the value proposition from a leading **supplier** in the chemical market.

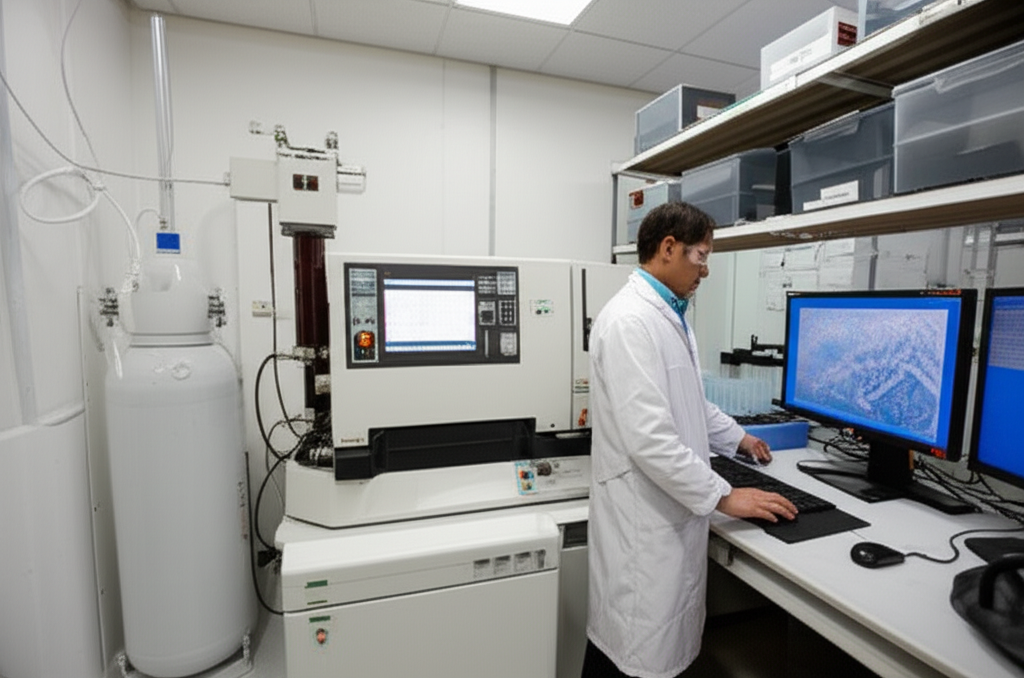

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.