A significant advancement has been developed in the synthesis of 6-chloro-5,12-naphthacenequinone, a critical intermediate compound essential for producing high-performance photochromic materials. These materials, specifically phenoxy-substituted naphthacenequinones, are highly valued in advanced optical technologies due to their exceptional fatigue resistance and thermal stability. Their potential applications span optical data storage, hologram recording, and optical switches, making efficient production of this intermediate paramount.

Traditional synthesis routes faced several challenges. The initial chlorination step of compound A (2-((1-hydroxy-2-naphthyl)carbonyl)benzoic acid) using phosphorus pentachloride (PCl5) was prone to generating unwanted side products. The high reactivity and strong hygroscopic nature of PCl5 often caused premature, partial ring closure during chlorination. This resulted in mixtures containing both the desired chlorinated intermediate, compound B (2-((1-chloro-2-naphthyl)carbonyl)benzoic acid) and the target naphthacenequinone simultaneously, requiring complex separation. Additionally, higher reaction temperatures (>140°C) risked PCl5 decomposition into chlorine gas, leading to further chlorination side reactions complicating purification. Furthermore, the subsequent ring closure step using concentrated sulfuric acid produced troublesome dark-colored acidic by-products, especially at higher temperatures, impacting product purity.

The improved process addresses these limitations through a carefully optimized two-step technique. In the crucial chlorination step, compound A is reacted with both PCl5 and phosphorus oxychloride (POCl3) at controlled temperatures between 120-130°C for 1-2 hours, using a specific mass ratio ratio of 1:(1.4-1.5):(0.5-1). The inclusion of POCl3 effectively suppresses premature ring closure, ensuring the primary product is compound B (2-((1-chloro-2-naphthyl)carbonyl)benzoic acid). After the reaction, the unreacted POCl3 is carefully distilled off to prevent violent hydrolysis upon quenching. Upon cooling, the intermediate undergoes a distinctive purification sequence. Hydrolysis is followed by alkali dissolution and acid precipitation, leveraging its carboxylic acid group. This efficiently isolates compound B in high purity after drying.

The second stage involves the ring closure reaction. The purified compound B is mixed with concentrated sulfuric acid (mass ratio 1:12) and reacted at 65-70°C for 1.5 hours. The reaction mixture is then carefully cooled and poured onto ice. The resultant solid, the crude 6-chloro-5,12-naphthacenequinone, is filtered and rigorously washed sequentially with water, ammonia solution (to remove acidic impurities), and water again. To achieve the highest purity, the final product undergoes a recrystallization step using dimethyl sulfoxide (DMSO) as the solvent before final drying.

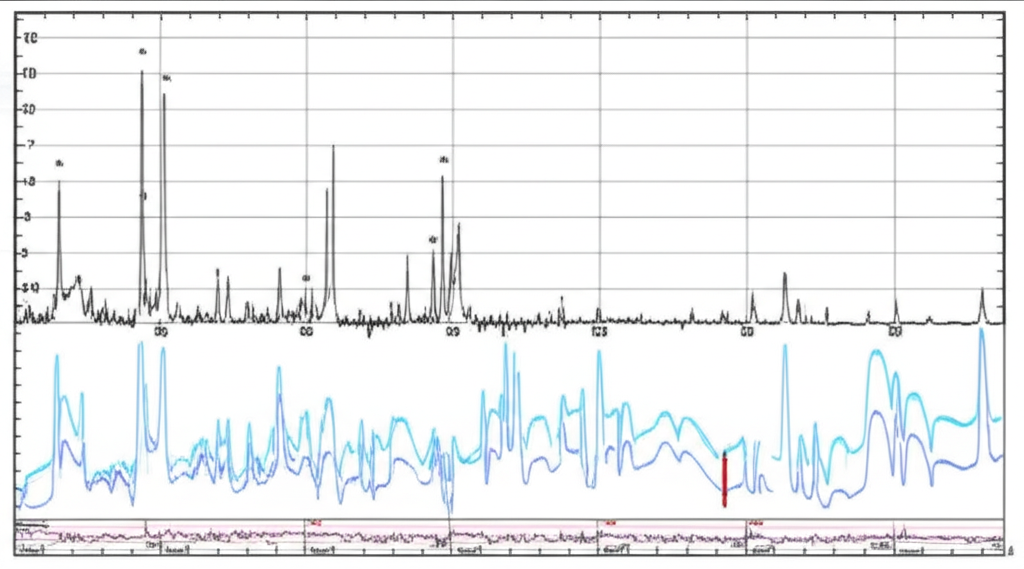

This novel synthesis route offers substantial benefits over the conventional approach. The chlorination reaction is much more selective and cleaner due to the presence of POCl3, ensuring high yield and simplifying the purification of the crucial intermediate. The well-defined two-step process (chlorination followed by ring closure) is operationally simpler. Furthermore, purification is highly effective: the selective dissolution/precipitation sequence isolates compound B cleanly before ring closure, minimizing acidic by-product issues downstream and the DMSO recrystallization efficiently yields pure product with minimal solvent consumption. Experimental results consistently demonstrate yields ranging from 55% to 62.7% across various tested conditions, significantly outperforming prior art. Confirmation of the structure included determination of its melting point at 263°C, along with characteristic Nuclear Magnetic Resonance (1H NMR) and Mass Spectrometry (EIMS: m/e = 292, 294 with a 3:1 intensity ratio) signatures matching 6-chloro-5,12-naphthacenequinone.

This optimized synthesis enhances the availability and purity of this vital photochromic intermediate, facilitating the development of next-generation optical devices and recording media.

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.