In the dynamic world of textile manufacturing, achieving a superior hand feel and exquisite texture is paramount. As consumer expectations rise, the demand for soft, smooth, and luxurious fabrics necessitates advanced finishing solutions. Recognizing this need, we are proud to introduce our state-of-the-art textile softener flakes, engineered with groundbreaking cold water dissolving technology. This innovative product represents a significant leap forward in textile auxiliary chemistry, offering unparalleled performance combined with enhanced ease of use and operational efficiency.

Traditional textile softeners often require heating to dissolve completely, adding time and energy costs to the finishing process. Our advanced flake formulation eliminates this requirement for most applications, allowing for rapid and complete dissolution in cold water. This not only translates into substantial energy savings but also streamlines preparation time, enabling textile mills to increase throughput and reduce overheads. The convenience of cold water dissolution makes this softener an exceptionally user-friendly option for diverse production environments.

Our textile softener is presented as a light yellow flake, designed for optimal handling and storage stability. It possesses a cationic ionicity, carefully selected to ensure effective interaction with textile fibers for maximum softening effect. The typical pH value of a 6-10% solution ranges from 4.5 to 6.5, a parameter crucial for maintaining product stability and compatibility with various finishing baths. This precise control over technical specifications guarantees consistent performance batch after batch.

The dissolving method is remarkably simple and efficient. For cold water preparation, flakes are gradually added to 30°C water at a concentration of 6-10% while stirring. After a brief stirring period of 3-5 minutes to ensure dispersion, the mixture is left to stand for 1-2 hours, during which the flakes hydrate and transform into a smooth, homogenous paste. A final slow stir prepares the paste for use. For operations where warm water is preferred or available, flakes can be added to room temperature water (6-10%), stirred for 3-5 minutes, and then heated to 50-60°C, stirring slowly for 30-60 minutes until a paste forms. The paste is then cooled before use. Both methods yield a stable and effective softening solution, with the cold water method offering distinct energy advantages.

The core property of this softener is its ability to provide fibers and textiles with an excellent soft and smooth hand feeling. It significantly enhances the tactile quality of finished fabrics, making them more appealing to the end consumer. This effect is particularly pronounced on natural fibers like cotton and synthetic blends such as polyester cotton (T/C), but its versatility extends to a wide range of chemical fibers as well. The result is a luxurious feel that elevates the perceived value of the textile product.

Beyond mere softness, this product also serves a crucial function in lubricating fibers and yarns. This lubrication is invaluable in mechanical finishing processes like sanding and napping, where reducing friction is essential to prevent fiber damage and achieve the desired surface texture. The softener ensures enhanced softness and improved texture throughout these processes, contributing to fabric strength and durability while making surfaces irresistibly smooth.

The application scope of this versatile softener is broad, making it ideal for various textile types and structures. It demonstrates exceptional effectiveness on knit, woven, and polyester cotton textiles. Its particular efficacy on cotton and T/C chemical fibers makes it a go-to solution for producers focusing on these widely used materials, ensuring they achieve top-tier softness and handle.

Detailed usage guidelines are available to help manufacturers achieve optimal results depending on their equipment and desired outcomes. The padding method, commonly employed in continuous finishing lines, is highly effective with a recommended dosage of 20-30g/L (calculated as 10% solution concentration) at a temperature of 30-40°C. Advanced technology can be utilized with either a one dip, one pad or two dips, two pads process to ensure even penetration and consistent application across the fabric width.

For batch processing, the dipping method is recommended. Here, a dosage of 3-8% (on weight of fabric, o.w.f) is used (again, based on the 10% solution). The optimal temperature range for dipping is 40-50°C. Maintaining a liquor ratio of 1:10 to 1:15 and a processing time of 30 minutes ensures thorough saturation and maximum softener uptake by the fibers, yielding a deep and lasting softness effect.

Quality is at the forefront of our operations. Each batch of textile softener flakes undergoes rigorous testing to ensure it meets our high standards for appearance, technical specifications, and performance. Our dedicated R&D team continually works to refine our products and develop innovative solutions that address the evolving needs of the textile industry, guaranteeing that our customers receive only the most effective and reliable finishing auxiliaries.

Packaging and storage are designed for convenience and product integrity. Our softener flakes are packaged securely in 25kg plastic woven bags, facilitating easy handling and transportation. To maintain the product's effectiveness, it should be stored for a period of 12 months in a cool, shady place, away from direct sunlight and moisture. Efficient shipping solutions are available to ensure timely delivery to destinations worldwide, supporting your production schedules.

In conclusion, our innovative cold water dissolving textile softener flakes offer a powerful combination of superior softening performance, ease of use, and operational efficiency. By choosing this advanced auxiliary, textile manufacturers can enhance the quality and appeal of their fabrics, reduce processing costs, and stay ahead in a competitive market. We are committed to providing high-quality chemical solutions that contribute to the success of our partners in the global textile industry.

If you are a textile manufacturer seeking a reliable supplier or trusted manufacturer of advanced textile finishing chemicals, we invite you to explore our product offerings. For inquiries regarding the specific price of our cold water dissolving softener flakes or to learn more about how to buy or purchase this product for your operations, please contact us. We are ready to provide detailed information, technical support, and assist you with placing your order to evaluate the benefits of our innovative softener firsthand.

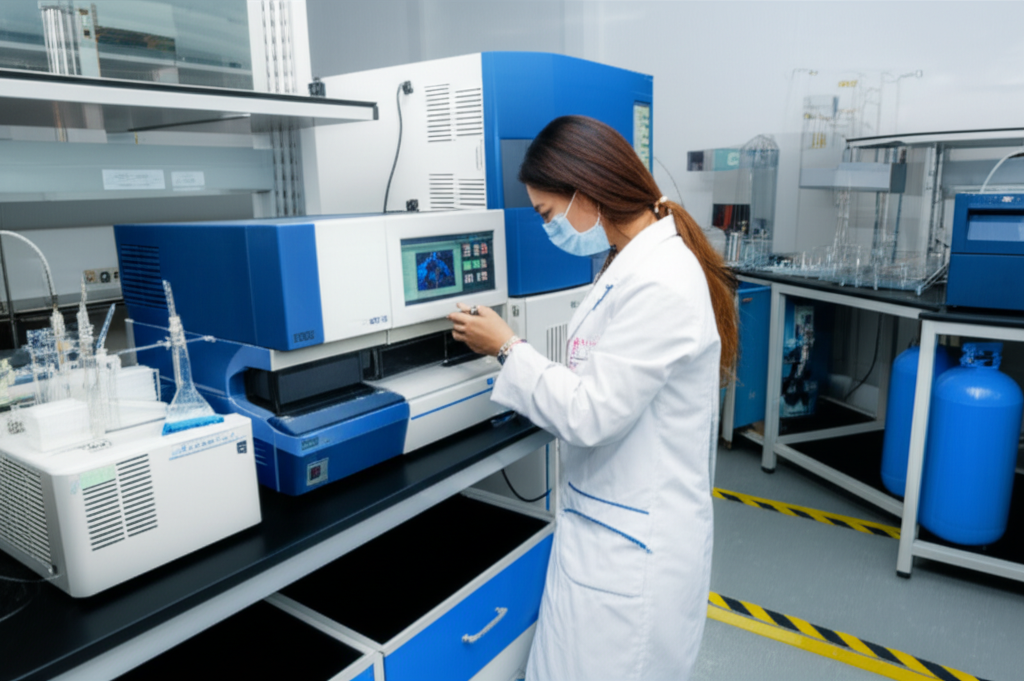

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.