In an era demanding heightened safety standards and environmental responsibility, the plastics industry faces an urgent need for effective flame retardant solutions. Traditional flame retardants, particularly those containing halogens, have raised significant concerns due to their potential toxicity and environmental persistence. They can leach into dust, contaminate indoor air, and are linked to adverse health effects such as developmental delays, hormone disruption, and increased cancer risk. This underscores the critical importance of transitioning to safer, more sustainable alternatives that do not compromise fire safety.

NINGBO INNO PHARMCHEM CO.,LTD. is proud to present its cutting-edge Halogen-Free Flame Retardant Masterbatch, specifically engineered for polypropylene (PP) film and related applications. This advanced masterbatch is formulated with a high concentration (50%) of active flame retardant components within a PP carrier, designed to deliver exceptional fire resistance for PP products. It achieves a UL-94 V-2 grade for 1.5mm thickness and an impressive GWIT of 750°C, setting a new standard for safety in its class. Furthermore, this masterbatch boasts excellent heat-resistant performance, offering an upgraded and environmentally superior alternative to conventional V-2 flame-retardant systems.

Our masterbatch is engineered through multiple product optimizations, resulting in enhanced fluidity during processing and reduced overall cost, making it a highly efficient solution for manufacturers. It is particularly well-suited for the flame-retardant treatment of polypropylene used in various critical applications. These include PP hollow boards, which are widely used in construction and packaging; electrical enclosures, where fire safety is paramount; and automotive interior plastic parts, contributing to vehicle safety standards.

A significant advantage of this product is its ease of integration into existing manufacturing processes. Customers can directly feed the masterbatch into a twin-screw extruder to produce their products, thereby eliminating the need for complex pre-mixing steps. This streamlined approach ensures no pollution to the workshop environment during production, promoting a cleaner and safer working space. For optimal flame-retardant effects in co-polymerized polypropylene, an addition amount of approximately 8% to 10% of this masterbatch is recommended. It is directly计量 and fed for injection molding, and can also accommodate a large amount of filler materials, providing flexibility in formulation.

Beyond its superior performance, environmental safety is at the core of our product's design. This Halogen-Free Flame Retardant Masterbatch features high whiteness, ensuring it does not adversely affect the color of the final product. It is inherently environmentally friendly, non-toxic, and smokeless, posing no detrimental impact on the environment during its lifecycle or in the event of a fire. The product fully complies with stringent EU environmental protection standards, including RoHS, and is entirely free from polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE). Its wide processing range and ability to pass demanding baking tests (e.g., 150°C/500hr or above) further attest to its stability and reliability. Compared to ordinary powdered flame retardant systems, this masterbatch offers higher dispersibility, significantly improving production stability, preventing product quality fluctuations, and reducing waste.

As a dedicated manufacturer and supplier of high-quality chemical solutions, NINGBO INNO PHARMCHEM CO.,LTD. is committed to providing innovative products that meet evolving industry needs. For competitive pricing and to buy or purchase our Halogen-Free Flame Retardant Masterbatch, please contact our sales team. We offer comprehensive support to ensure our product seamlessly integrates into your production process, helping you achieve superior fire safety standards for your polypropylene film and related plastic products.

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

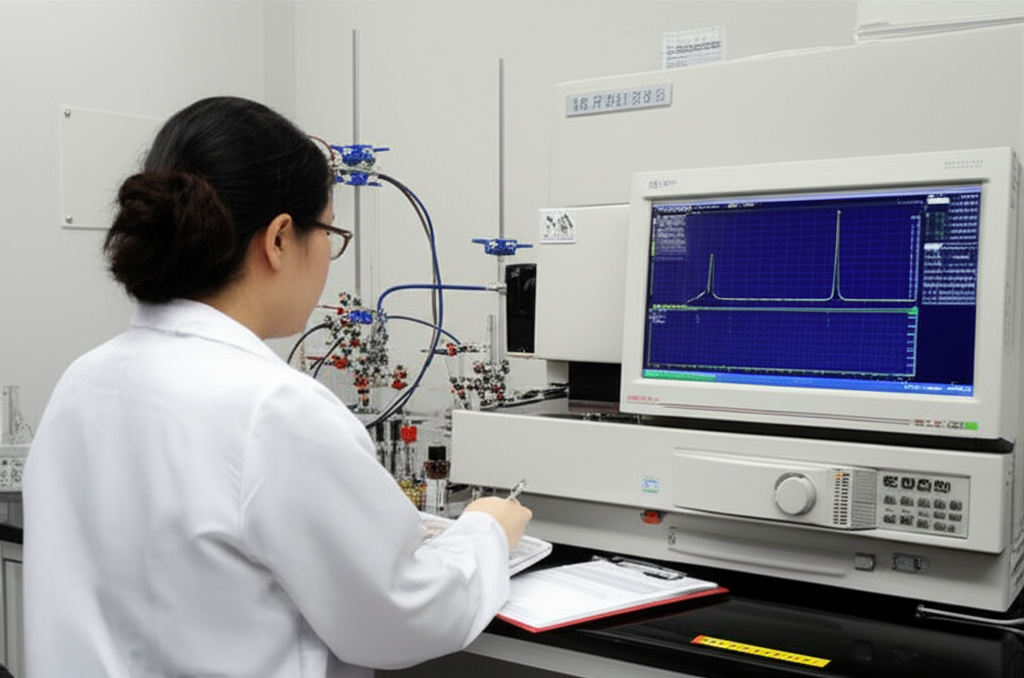

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.