In the dynamic world of plastic manufacturing, achieving optimal melt flow characteristics is crucial for efficient processing and high-quality end products. Manufacturers constantly seek innovative solutions to modify polymer properties to suit diverse application requirements. Addressing this need, a high-performance PE MFI Additive has been developed as a granular plastic auxiliary agent, specifically designed to optimize the melt flow index (MFI) of both polypropylene (PP) and polyethylene (PE) resins.

This advanced MFI modifier serves a dual purpose: it effectively increases the melt flow index of PP while simultaneously decreasing the melt flow index of PE. This capability is invaluable for improving the fluidity and dispersity of resins during processing, leading to enhanced production efficiency and superior product consistency. By adjusting the MFI, this additive allows for greater control over processing parameters, making it possible to utilize a wider range of production techniques.

Presented in a convenient granular masterbatch form with a white appearance, this additive boasts a remarkably high effective substance content. Its low addition percentage, typically ranging from 2% to 4%, makes it a cost-effective solution for plastic modification. The additive integrates smoothly into existing production lines, requiring simple mixing with the resin before processing.

The benefits of incorporating this MFI additive are substantial. For PP, it can significantly boost the MFI, even transforming low-flow extrusion grade PP into high melt flow injection grade material. Conversely, when used with PE, it can decrease the MFI, allowing high melt flow injection grade PE to be modified for extrusion applications. This versatility supports a wide array of applications including plastic injection molding, extrusion, blowing, as well as the production of pipes, boards, sheets, yarns, and house appliances. It is equally effective in modifying both new virgin resins and recycled plastic materials, promoting sustainability in manufacturing.

Beyond its primary function of MFI modification, this additive offers additional advantages. It can improve the resins' melt flow and fluidity inside processing machinery by over 50%, leading to noticeable gains in throughput and energy efficiency. The product adheres to stringent environmental standards, holding certifications such as ROHS and Food Contact approval, ensuring safety and compliance. Its low dosage requirement translates into significant cost savings without compromising performance. With a strong focus on quality, the additive is manufactured to provide reliable performance and durability.

For businesses looking to optimize their plastic processing and enhance material performance, finding a dependable *manufacturer* and *supplier* is key. This PE MFI Additive is available for those seeking to *buy* or *purchase* high-quality plastic auxiliaries. Information regarding *price* is typically available upon inquiry, often varying based on quantity ordered. To facilitate testing and evaluation before a bulk *purchase*, samples are usually available. Engaging with a dedicated *manufacturer* ensures access to technical support and product expertise, making the *buy* process straightforward and informed for optimizing PP and PE processing needs.

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

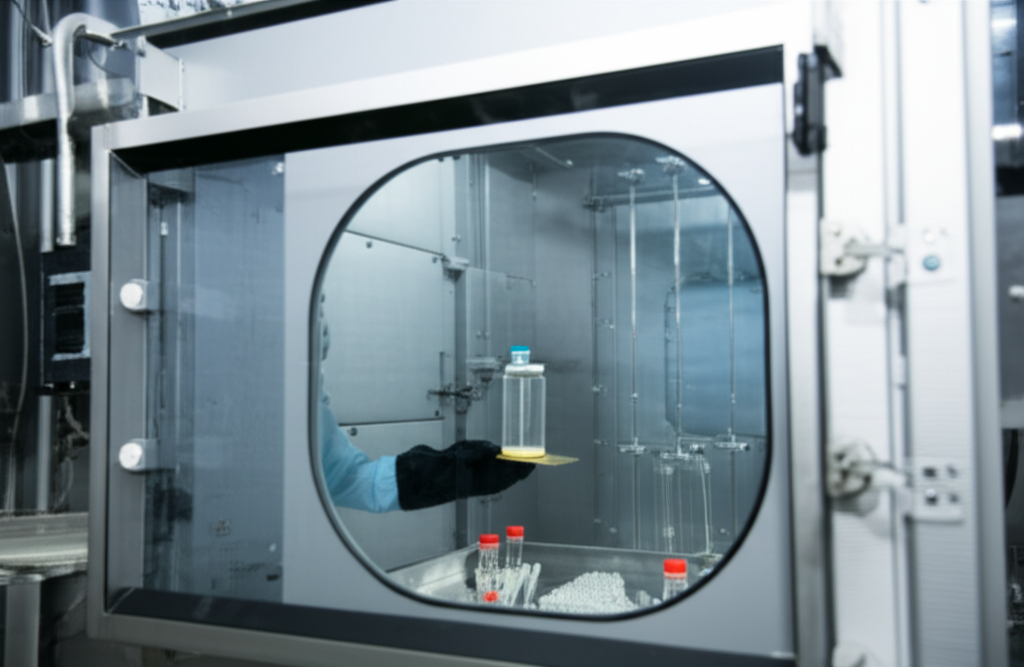

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.