Tert-Butyl Hydroperoxide (TBHP), identified by its CAS number 75-91-2, stands as a pivotal chemical compound within the realm of organic peroxides. This substance is a colorless transparent liquid at typical conditions, possessing the molecular formula C4H10O2. Its unique chemical structure makes it an invaluable tool across numerous industrial applications, primarily serving as an oxidant, a catalyst, and importantly, a radical initiator.

One of the most significant applications of TBHP CAS 75-91-2 is its role in emulsion polymerization. This process is fundamental to the production of various polymers, including synthetic rubbers like styrene-butadiene rubber (SBR), acrylic polymers, and vinyl acetate polymers. In emulsion polymerization, TBHP acts as the initiator, generating free radicals that trigger the polymerization of monomers dispersed in an aqueous medium. The effectiveness of TBHP in this context stems from its controlled decomposition properties, which allow for fine-tuning the polymerization rate and influencing the molecular weight and properties of the final polymer. Its use contributes to stable latex dispersions, which are critical for coatings, adhesives, and various other materials.

Beyond emulsion polymerization, Tert-Butyl Hydroperoxide finds extensive utility as a versatile oxidant and catalyst in organic synthesis. It is frequently employed in epoxidation reactions, particularly the Sharpless epoxidation, a highly selective method for converting allylic alcohols into epoxy alcohols. TBHP can also participate in other oxidation processes, facilitating the transformation of various organic substrates. Its reactivity can be modulated by different metal catalysts, allowing for tailored chemical transformations in laboratory and industrial settings.

Furthermore, TBHP CAS 75-91-2 serves as a bleaching agent in industries such as textiles and paper. Its oxidative power helps to remove color impurities, contributing to the brightness and whiteness of materials. While other bleaching agents exist, TBHP offers specific advantages depending on the application and the material being treated. It also finds niche uses as a deodorant, leveraging its oxidative properties to neutralize odor-causing compounds.

The compound is also a crucial crosslinking agent for unsaturated polyesters and plays a role in the vulcanization of rubber. In unsaturated polyester resins, TBHP, often in conjunction with accelerators, initiates the crosslinking process, leading to the curing of the resin into a rigid or semi-rigid material used in fiberglass composites, coatings, and other applications. For rubber vulcanization, particularly with certain types of rubber, TBHP can act as an alternative curing agent, influencing the final physical properties of the rubber product.

Another important application is its use as an initiator or co-initiator in the production of odorless Dicumyl Peroxide (DCP). DCP is a common crosslinking agent for polyolefins and rubbers, and using TBHP in its synthesis contributes to a product with reduced odor, which is desirable for many downstream applications.

The industrial availability of Tert-Butyl Hydroperoxide 70% min assay ensures its broad adoption across these diverse sectors. Quality control is paramount when dealing with organic peroxides due to their reactive nature. Parameters such as assay percentage, and the levels of impurities like Tert-Butyl Alcohol (TBA) and water, are critical indicators of product purity and performance consistency in intended applications. Suppliers must adhere to stringent quality standards to ensure the safety and efficacy of the product for their customers.

Given its wide array of critical applications, sourcing high-quality Tert-Butyl Hydroperoxide CAS 75-91-2 from a reliable partner is essential for manufacturers in the polymer, chemical synthesis, and material processing industries. A dependable TBHP manufacturer and Tert-Butyl Hydroperoxide supplier can provide the necessary technical support and consistent product quality required for demanding industrial processes.

For companies seeking a trustworthy source for this vital organic peroxide, NINGBO INNO PHARMCHEM CO.,LTD. is positioned to meet global supply needs. NINGBO INNO PHARMCHEM CO.,LTD. understands the complexities involved in the production and handling of such reactive chemicals and is committed to delivering products that meet rigorous quality specifications.

When considering the TBHP price, it is important to factor in quality, purity, and the reliability of supply, as these elements directly impact production efficiency and the quality of the final product. NINGBO INNO PHARMCHEM CO.,LTD. aims to offer competitive pricing while maintaining high standards of product integrity and customer service.

Those looking to buy Tert-Butyl Hydroperoxide or purchase TBHP CAS 75-91-2 can explore procurement options through established supply channels. Partnering with an experienced Tert-Butyl Hydroperoxide manufacturer ensures access to product that is manufactured under controlled conditions and handled with appropriate safety protocols.

Securing a consistent and reliable Tert-Butyl Hydroperoxide supplier is key for uninterrupted manufacturing processes. NINGBO INNO PHARMCHEM CO.,LTD. is focused on building long-term relationships with customers by providing dependable supply chains and responsive service.

In summary, Tert-Butyl Hydroperoxide (TBHP) CAS 75-91-2 is an indispensable chemical for numerous industrial applications, driven by its powerful initiating and oxidizing capabilities. Its pivotal role in emulsion polymerization, catalysis, and crosslinking underscores its importance. For manufacturers globally, identifying a reputable TBHP manufacturer and Tert-Butyl Hydroperoxide supplier is crucial for operational success and product excellence. NINGBO INNO PHARMCHEM CO.,LTD. is dedicated to being that reliable partner, facilitating access to high-quality TBHP for diverse industrial requirements. Inquiries regarding TBHP price or processes to buy Tert-Butyl Hydroperoxide are welcome, ensuring clients can readily access the material they need.

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

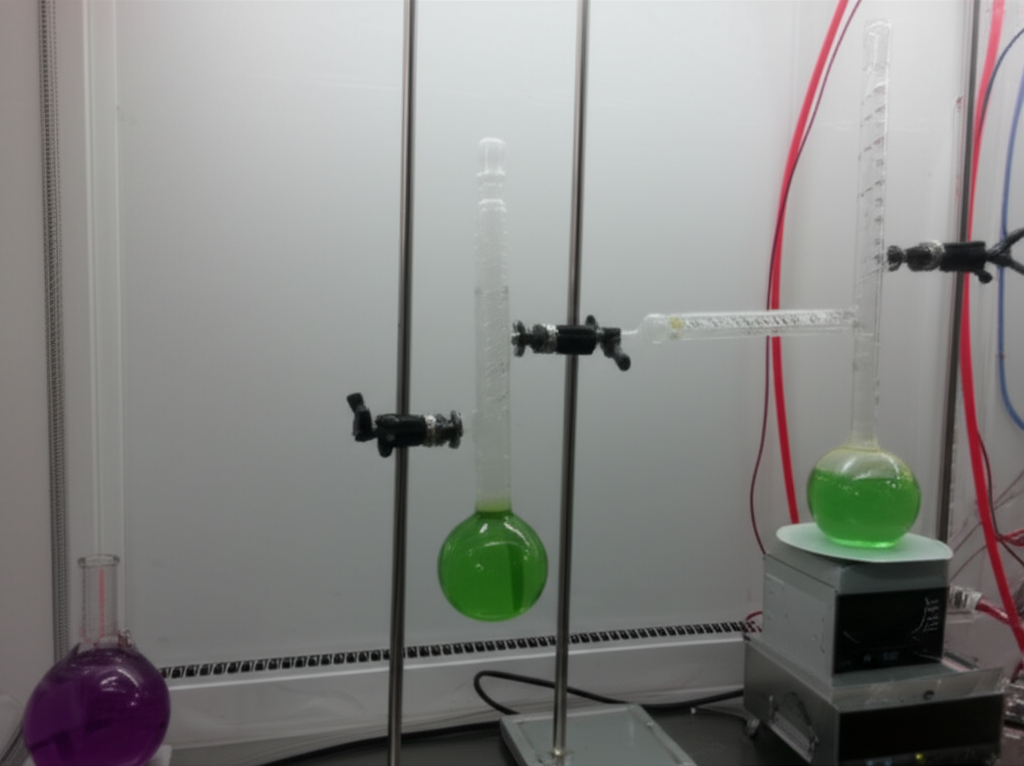

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.