Chlorinated Paraffin 52, commonly referred to as CP52, stands as a crucial chemical raw material widely employed across various industrial sectors. This substance is a chlorinated derivative of paraffin hydrocarbons, presenting typically as a transparent oily liquid that ranges in color from yellowish to colorless depending on the specific grade and purity. Its unique combination of properties makes it invaluable as both a secondary plasticizer and an effective flame retardant.

As a secondary plasticizer, CP52 is frequently utilized in conjunction with primary plasticizers, particularly in the processing of Polyvinyl Chloride (PVC) and related materials. Plasticizers are essential additives that increase the flexibility, workability, and extensibility of polymers that would otherwise be rigid and brittle. CP52 contributes to enhancing the physical properties of the final product, such as elongation and tensile strength, while also offering economic advantages by partially replacing more expensive primary plasticizers without significantly compromising performance. Its compatibility with PVC resins ensures smooth integration into the manufacturing process.

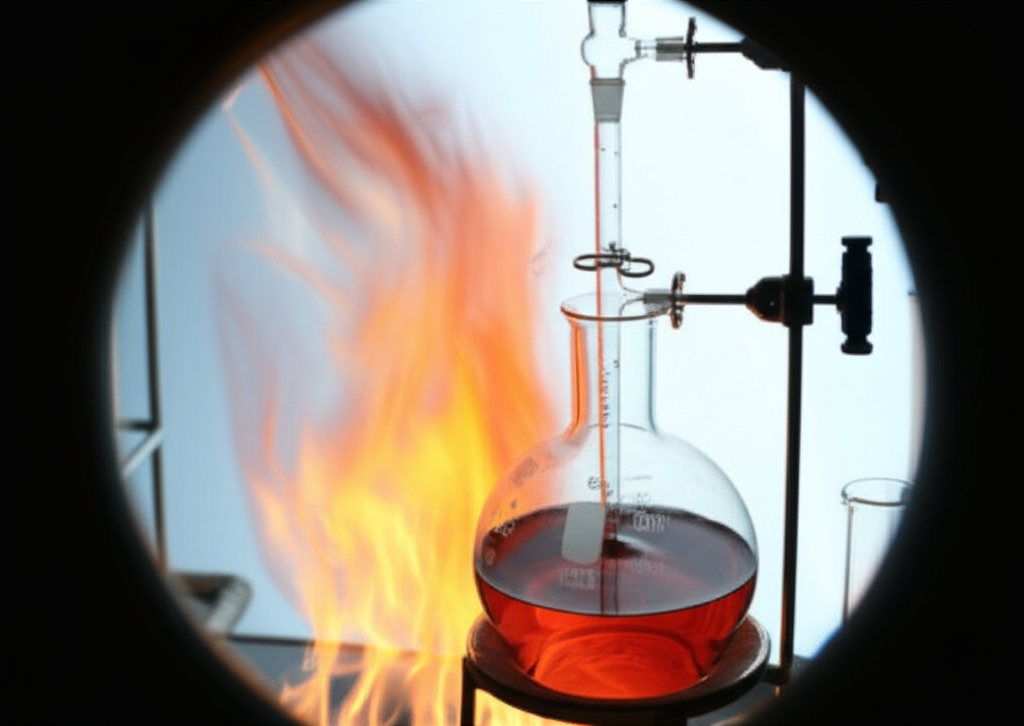

Beyond its plasticizing capabilities, one of the most significant roles of Chlorinated Paraffin 52 is its function as a flame retardant. Organic materials, especially polymers, can be highly flammable. Incorporating flame retardants is critical for improving safety standards in numerous applications. CP52 achieves flame retardancy through the release of hydrogen chloride when exposed to heat. This gas can interrupt the combustion process in the gas phase, while the formation of char on the surface can help create a barrier, insulating the underlying material from heat and oxygen. This property is particularly vital in applications where fire safety is paramount.

The versatile nature of CP52 leads to its application in a broad spectrum of products. In the construction and electrical industries, it is extensively used in cable materials and wire insulation, where flexibility, electrical insulation, and flame retardancy are non-negotiable requirements. Its inclusion helps meet stringent safety regulations by reducing the risk of fire propagation.

In the manufacturing of consumer goods and industrial components, CP52 finds its way into materials such as sheet metal coatings, providing improved film formation, flexibility, and resistance properties. It is also a component in the production of hoses and artificial leather, contributing to their flexibility, durability, and longevity under various conditions.

The rubber industry also benefits from the use of Chlorinated Paraffin 52. When added to rubber compounds, it can act as a processing aid, improving the ease with which rubber is mixed and shaped. Furthermore, it can enhance the final physical characteristics of the rubber product, potentially including improved resistance to wear and tear.

Other notable applications include its use in certain types of coatings, where it can improve adhesion, flexibility, and surface finish. Additionally, specific grades can be utilized as additives in lubricating oils, contributing properties such as enhanced lubricity or anti-wear capabilities under demanding operational conditions.

Several key physical and chemical characteristics underscore the suitability of CP52 for these diverse uses. Its low volatility ensures that the additive remains stable within the finished product over time, preventing migration that could lead to loss of properties or surface issues like blooming. Its stable chemical condition means it does not readily degrade under normal storage and processing conditions, contributing to a reliable and consistent performance. Furthermore, its inherent good electrical insulation properties make it an ideal choice for electrical applications where preventing current leakage is essential.

Manufacturers of high-quality Chlorinated Paraffin 52 adhere to rigorous production standards to ensure consistency and performance. Specifications typically monitored include parameters such as Chlorine Content, Viscosity at a standard temperature, Density, Thermal Decomposition Point, and Color. These specifications are crucial for ensuring the product performs as expected in downstream applications and meets international quality benchmarks. Reliable supply chains ensure the product is available in standard packaging options, including drums, IBC containers, and bulk flexitanks, catering to the varying needs of industrial users.

The combination of its technical performance, cost-effectiveness, and wide applicability solidifies Chlorinated Paraffin 52's position as an indispensable chemical raw material in modern manufacturing. Its ability to impart both flexibility and flame retardancy, alongside its favorable physical properties, makes it a go-to additive for improving product safety, durability, and processability across numerous industries.

Potential buyers seeking a reliable manufacturer or supplier of high-quality Chlorinated Paraffin 52 can inquire about current market price. Detailed specifications and samples are typically available upon request to facilitate assessment before committing to a large order. To learn more about how to buy or purchase CP52, details regarding price and sourcing options are readily available from experienced suppliers catering to various industrial needs. Establishing a direct relationship with a qualified manufacturer can often provide the most competitive price and ensure consistent supply tailored to specific application requirements.

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.