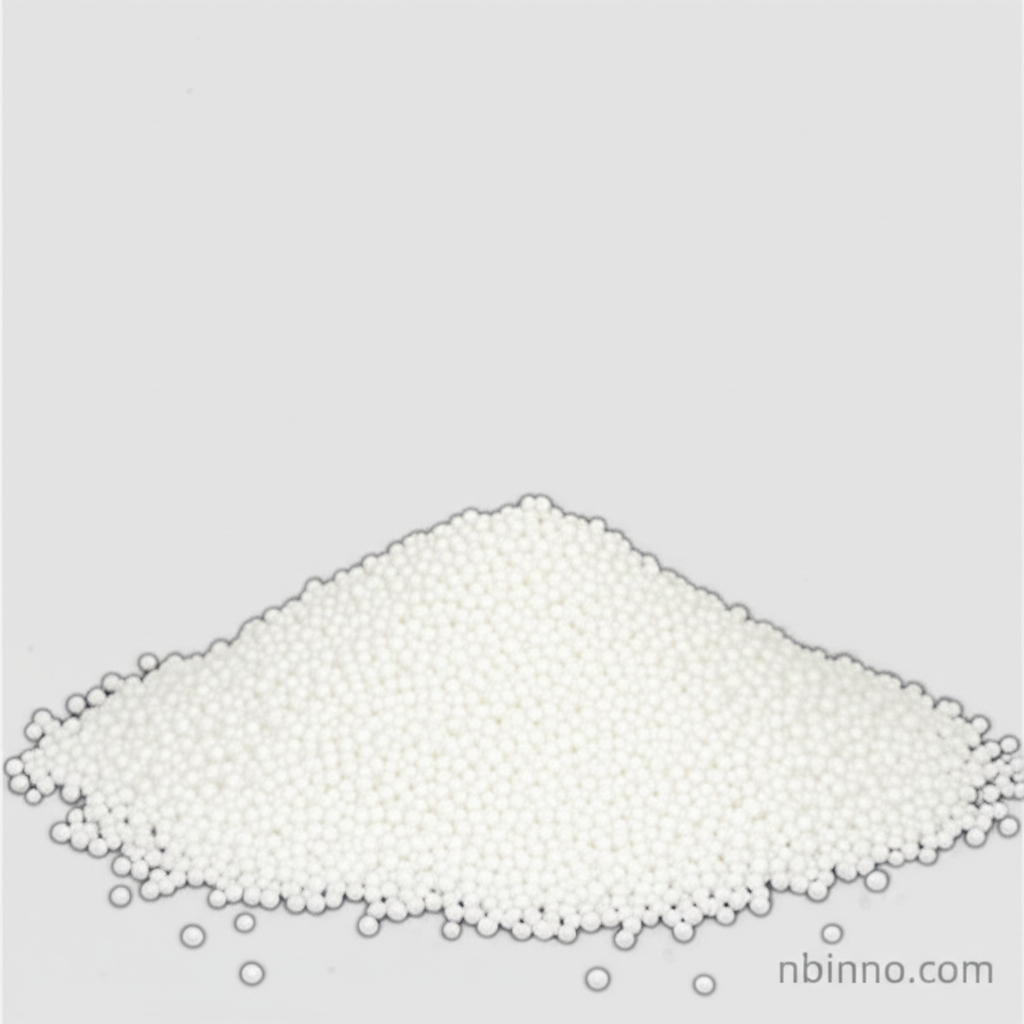

Hollow Silica Microspheres: Lightweight Fillers for Enhanced Coatings & Composites

Discover the superior benefits of hollow silica microspheres, an advanced material engineered to significantly reduce weight and improve performance in your coating and composite formulations. Source from a reliable manufacturer in China for cost-effective solutions.

Get a Quote & SampleRevolutionize Your Formulations with High-Performance Hollow Silica Microspheres

Premium Hollow Silica Microspheres

As a leading supplier and manufacturer in China, we offer premium hollow silica microspheres designed to enhance a wide array of applications. These borosilicate glass microspheres are characterized by their low density, high crush strength, and exceptional chemical stability, making them an ideal choice for formulators seeking to improve product performance and reduce material costs. Purchase these versatile additives to gain a competitive edge.

- Lightweighting Solutions: Significantly reduce the density of paints, coatings, and composites, leading to substantial material savings and improved handling. Explore options to buy wholesale for large-scale projects.

- Enhanced Thermal and Acoustic Insulation: Benefit from the inherent insulating properties of hollow silica spheres, improving the thermal and soundproofing capabilities of your end products. Inquire about bulk pricing and availability from our China-based facility.

- Improved Mechanical Properties: Enhance rigidity, impact resistance, and overall mechanical performance of composite materials. As your trusted supplier, we provide consistent quality for your manufacturing needs.

- Excellent Dispersibility: Our treated hollow glass microspheres ensure easy and uniform dispersion in various organic resins and binders, simplifying your formulation process. Request a quote to secure your supply chain.

Key Advantages of Our Hollow Silica Microspheres

Superior Lightweighting

Achieve significant weight reduction in your products without compromising structural integrity. These hollow silica spheres are a top choice for manufacturers aiming to optimize material usage and reduce shipping costs. We are a premier manufacturer offering competitive pricing.

Exceptional Thermal Performance

Leverage the low thermal conductivity of our microspheres to create highly effective thermal insulation systems for coatings and construction materials. Consider purchasing from our dedicated supplier in China for your insulation formulation needs.

Enhanced Product Durability

Improve the overall durability and performance of your materials through increased rigidity and impact resistance. Our hollow silica spheres contribute to longer product lifespans, making them a wise investment for any discerning buyer.

Diverse Applications for Hollow Silica Microspheres

Paints & Coatings

Enhance rheology, reduce shrinkage, and improve insulating properties in architectural, automotive, and industrial coatings. Explore our product catalog to buy for your painting formulations.

Plastics & Composites

Lightweight plastics, BMC, SMC, and high-performance composites for automotive, aerospace, and marine industries. Partner with a reliable manufacturer for your composite material needs.

Construction Materials

Improve thermal insulation and reduce density in cements, mortars, grouts, and stucco. We are a trusted supplier for construction chemical manufacturers seeking quality additives.

Specialty Applications

Ideal for explosives, refractories, and as insulating materials in various high-temperature environments. Contact us for a detailed quote and sample to evaluate performance.