Eco-Friendly Soaping Agent for Efficient Reactive Dye Removal

Experience superior textile quality and sustainability with our advanced soaping agent, designed for optimal reactive dye removal at lower temperatures, significantly reducing energy and water consumption.

Get a Quote & SampleProduct Core Value

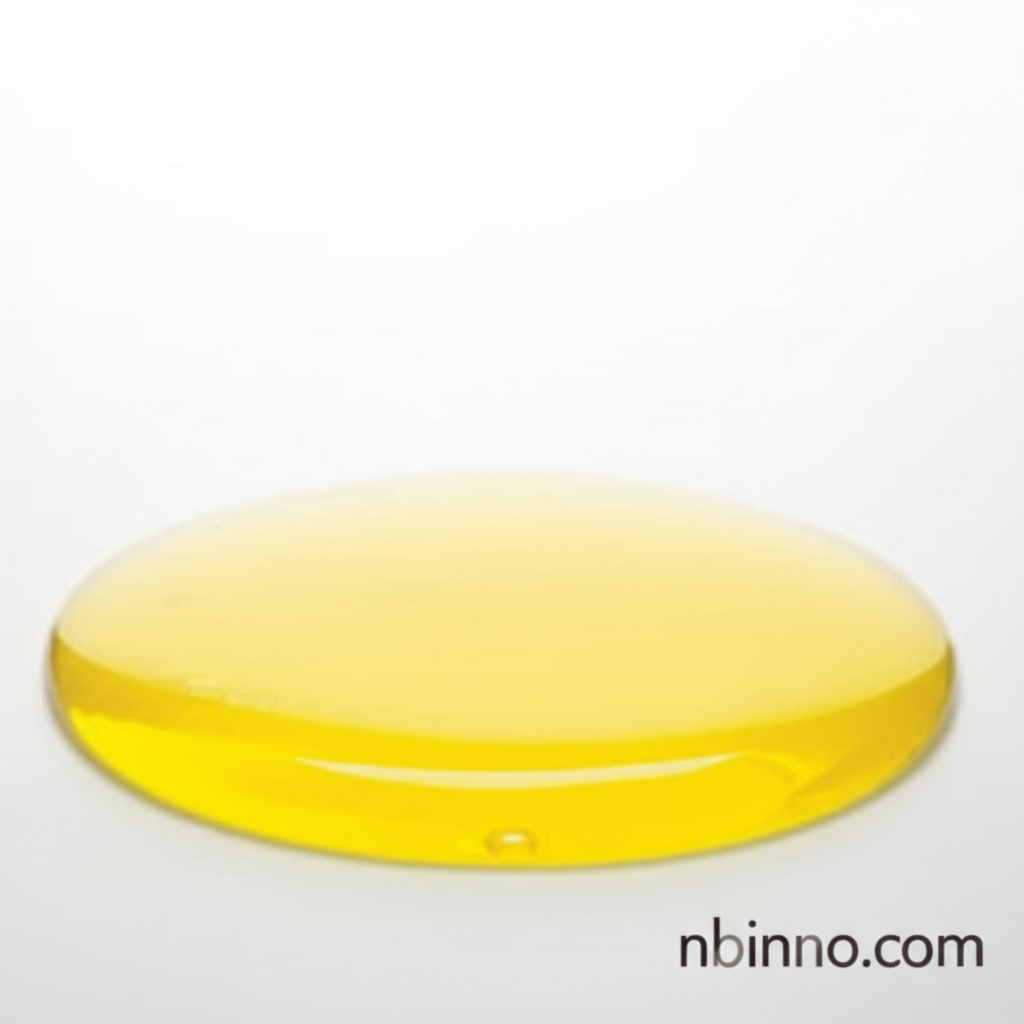

Soaping Agent

As a leading supplier in China, we offer an advanced soaping agent specifically engineered for cellulose fiber fabrics. Our product excels at removing unfixed reactive dyes, ensuring vibrant colors and excellent fastness. It is an environmentally friendly solution that meets the evolving demands of modern textile technology and stringent environmental standards. We are committed to providing high-performance chemical auxiliaries.

- Discover the benefits of using an effective reactive dye removal agent to achieve impeccable results in your textile production.

- Optimize your process with our low temperature textile soaping solution, dramatically cutting down energy consumption without compromising efficiency.

- Embrace an eco-friendly cellulose fiber aftertreatment that meets stringent environmental standards, contributing to a greener production cycle.

- Boost productivity through our energy saving dyeing auxiliary, reducing processing times and operational costs effectively for businesses looking for cost savings.

Advantages Provided by the Product

Enhanced Productivity & Cost Savings

Our Soaping Agent allows for soaping at a lower temperature of 80°C, significantly reducing energy and water consumption. This leads to higher productivity and substantial cost savings, streamlining your reactive dyeing process optimization.

Unmatched Versatility & Stability

The effectiveness of this textile auxiliary agent is not influenced by pH, salt concentration, or water quality, making it universally applicable across various equipment and dyeing conditions, enhancing its utility for cellulose fiber processing.

Environmental Compliance & Ease of Use

This product is fully environmentally friendly, stable under recommended storage conditions, and straightforward to measure and operate. This makes it an ideal choice for sustainable textile dyeing practices, simplifying your production workflow.

Key Applications

Reactive Dyeing Aftertreatment

Essential for efficient reactive dyeing aftertreatment in cellulose fiber fabrics, ensuring thorough removal of unfixed dyes for excellent colorfastness and overall fabric integrity.

Low-Temperature Processing

Ideal for achieving optimal results with a low temperature textile soaping solution, enabling significant energy savings without compromising on efficiency or the quality of the finished textiles.

Blended Fabric Finishing

This versatile agent is also highly effective for blended fabric finishing, extending its utility across a wider range of textile materials and complex dyeing needs, ensuring consistent results.

Washing & Desizing Processes

Can be effectively utilized for cotton washing and desizing of cotton skein, bobbin yarn, knitted, and woven yarn-dyed fabrics, streamlining multiple stages of textile preparation and improving workflow.