High-Performance Flame Retardant Plasticizer: Enhancing Safety and Durability in Polymers

Discover the critical role of Cresyl Diphenyl Phosphate (CDP) in improving the fire safety and mechanical properties of a wide array of industrial materials, from advanced polymers to essential coatings.

Get a Quote & SampleProduct Core Value

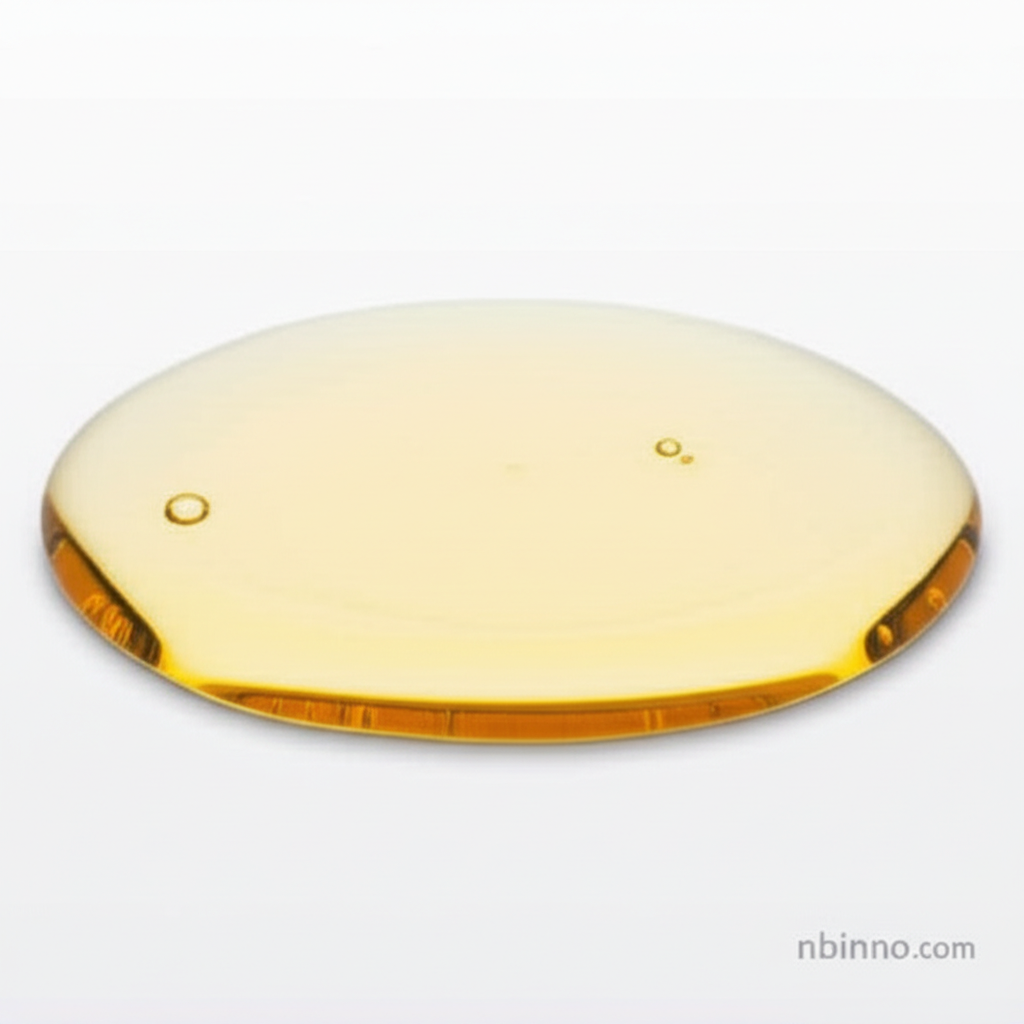

Cresyl Diphenyl Phosphate

As a leading supplier in China, we offer Cresyl Diphenyl Phosphate (CDP), a highly effective organophosphate compound renowned for its dual functionality as a flame retardant and plasticizer. Its unique chemical structure provides exceptional thermal stability, making it an indispensable additive for materials requiring enhanced fire resistance and flexibility. We are committed to delivering high-quality chemical solutions that meet stringent industry standards.

- Discover the superior flame retardancy provided by CDP, a key factor when looking for high-performance flame retardant solutions for advanced materials.

- Explore the excellent plasticizing efficiency of CDP, which improves flexibility and workability in polymers, enhancing the overall material performance.

- Leverage the good electrical insulation properties of CDP, crucial for applications in the electronics and automotive sectors.

- Benefit from the superior hydrolytic stability and low volatility of CDP, ensuring long-term performance and reliability in demanding environments.

Advantages Offered

Enhanced Fire Safety

CDP significantly boosts the fire resistance of various materials, crucial for meeting safety regulations and protecting assets. Its effectiveness as a flame retardant contributes to safer product designs.

Improved Material Flexibility

As a plasticizer, CDP enhances the flexibility and workability of polymers. This improves the processing and end-use performance, particularly for flexible PVC and rubber applications.

Thermal and Chemical Stability

The inherent stability of CDP ensures materials maintain their integrity under heat and stress, contributing to the longevity and reliability of finished products, vital for applications demanding durable materials.

Key Applications

PVC and Polymer Modification

CDP is extensively used as a flame retardant plasticizer in PVC, PU foams, and various synthetic rubbers, enhancing both fire safety and flexibility in extruded articles like cables and hoses.

Coatings and Lacquers

In coatings, CDP improves fire retardancy and flexibility for nitrocellulose lacquers and phenolic resins, ensuring durable and safe finishes for industrial applications.

Lubricants and Hydraulic Fluids

CDP serves as a component in high-performance lubricants and non-flammable hydraulic fluids, offering enhanced thermal stability and wear resistance in demanding industrial environments.

Automotive and Electronics

Its properties make CDP essential for components in the automotive and electronics industries where fire safety and material durability are paramount, contributing to safer consumer products.