Oleamide: A Versatile Slip Agent for Enhanced Polymer Processing and Product Performance

Discover the key benefits and applications of Oleamide, the essential slip agent that optimizes plastic manufacturing.

Get a Quote & SampleProduct Core Value

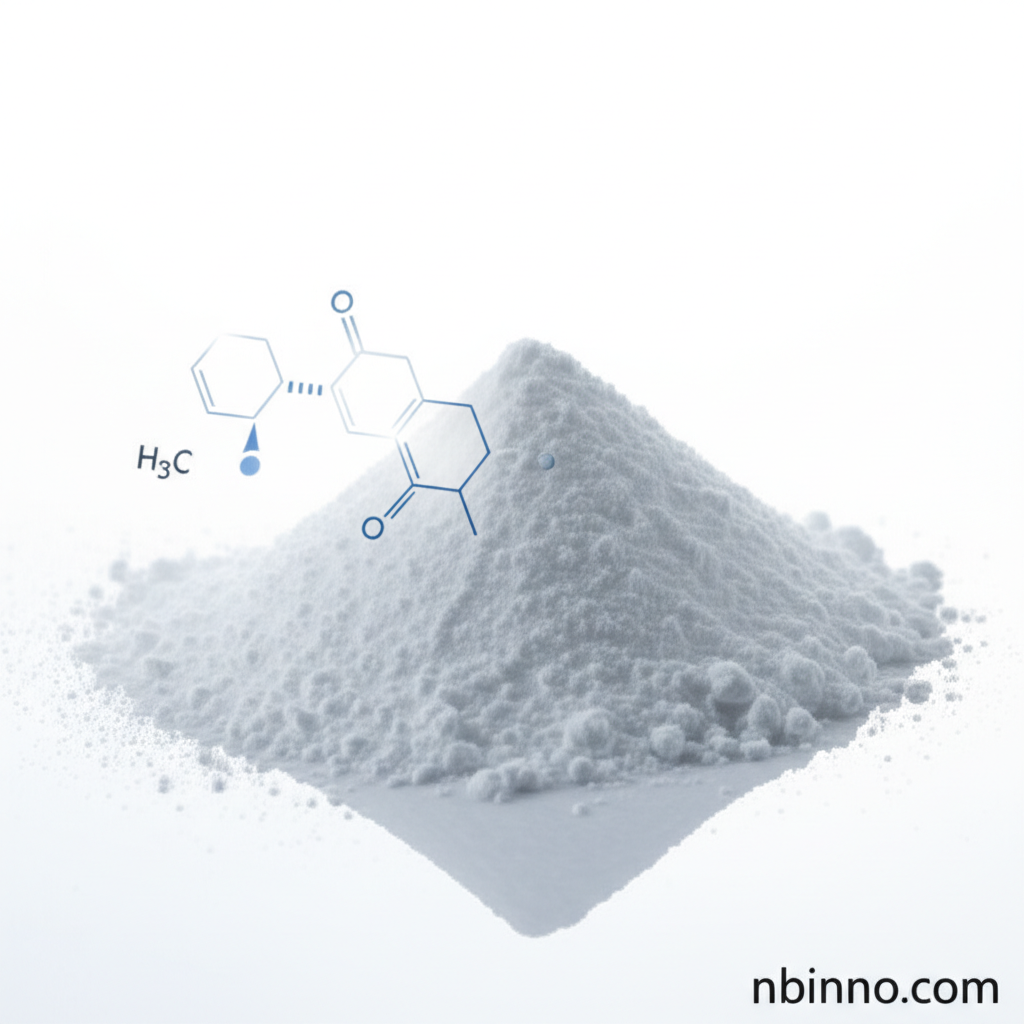

Oleamide

Oleamide is a critical fatty acid amide that plays a pivotal role in enhancing polymer processing and the performance of plastic products. Its primary function is to act as a slip agent, significantly reducing friction both internally within the polymer and externally between the polymer and processing equipment. This leads to smoother operations, increased production volumes, and improved final product quality. Its properties make it an indispensable additive for a wide range of plastic applications.

- Explore the benefits of oleamide in polymer processing, including reduced internal friction between polymer molecules, leading to better flow characteristics during manufacturing.

- Understand the lubrication properties of oleamide, which provide a smooth gliding layer on surfaces, minimizing wear on machinery and facilitating easier handling of plastic films.

- Learn about the anti-static oleamide applications, which help dissipate static electricity, preventing dust accumulation and improving the safety and usability of finished plastic goods.

- Discover the efficacy of oleamide for film production, where it acts as an anti-sticking agent, preventing films from adhering to each other and ensuring easy unwinding and processing.

Advantages of Oleamide

Enhanced Processability

Oleamide significantly reduces friction, allowing for smoother processing of polymers. This translates to higher production speeds and reduced energy consumption, a key benefit when considering best slip agent for polyolefins.

Improved Product Handling

The anti-sticking and anti-static properties derived from Oleamide's application ensure that plastic films and products are easy to handle, open, and process, a crucial aspect for packaging and consumer goods.

Superior Surface Properties

Oleamide contributes to desirable surface characteristics, such as reduced scuffing and scratching, enhancing the aesthetic appeal and durability of the final plastic product.

Key Applications

Polymer Film Manufacturing

Essential for producing high-quality films used in packaging, Oleamide ensures easy unwinding and prevents blocking, vital for efficient production processes.

Plastic Products

Used in a wide array of plastic goods to improve mold release, reduce friction, and enhance overall durability and handling characteristics.

Lubricants and Coatings

Oleamide serves as a component in industrial lubricants and coatings, providing slip and anti-corrosion properties for metal surfaces.

Masterbatch Production

As a dispersing agent for pigments and colorants in masterbatches, Oleamide ensures uniform color distribution and improves the quality of colored plastics.