Hydroxypropyl Methylcellulose, widely known as HPMC or Hypromellose, is a versatile and essential non-ionic cellulose ether that plays a critical role across numerous industries. This semi-synthetic, inactive, and viscoelastic polymer is derived from cellulose, a natural and abundant resource. Its unique combination of properties makes it an indispensable ingredient in applications ranging from pharmaceuticals and food products to construction materials and cosmetics.

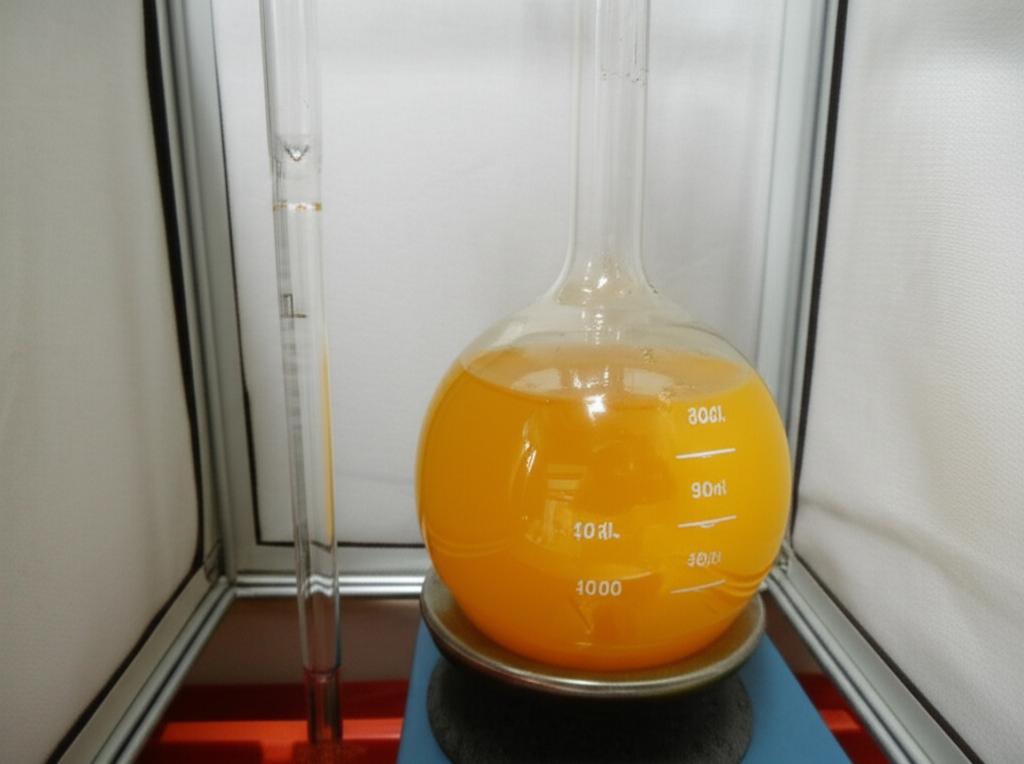

HPMC presents as a white or off-white fibrous or granular powder. A key characteristic is its solubility in cold water, which forms a clear to slightly hazy solution. Upon heating, these solutions exhibit a unique thermal gelation property, solidifying at a specific temperature and returning to a solution upon cooling. This reversible thermal gelation is leveraged in various applications, particularly in food. HPMC also possesses excellent film-forming capabilities, creating strong, flexible, and transparent films. Furthermore, it acts as an effective thickener, viscosity modifier, suspending agent, and water retention agent. The viscosity of HPMC solutions varies depending on the molecular weight and degree of substitution, commonly specified within a wide range, such as 3,000 to 200,000 mPa.s, allowing for tailored performance in different formulations. High purity, typically exceeding 99%, is paramount, especially for sensitive applications like pharmaceuticals and food. The product is stable, boasting a typical shelf life of two years when stored under appropriate conditions.

To meet the specific requirements of its broad application spectrum, HPMC is produced in different grades. The most prominent include Food Grade HPMC, Pharmaceutical Grade HPMC, and Industrial Grade HPMC. Pharmaceutical Grade HPMC adheres to the most stringent purity and quality standards, complying with major pharmacopoeias such as the United States Pharmacopeia (USP) and the British Pharmacopoeia (BP). Production follows Good Manufacturing Practices (GMP) and often includes ISO 9001 certification, ensuring safety, efficacy, and consistency for use in medications. Food Grade HPMC also requires high purity and compliance with food safety regulations, acting as a safe additive for consumption. Industrial Grade HPMC, while still requiring quality control, may have less strict purity requirements depending on the specific application, such as in construction mortars or paints. The choice of grade is critical to ensure the product performs correctly and meets all safety and regulatory requirements for its intended use.

The Pharmaceutical Grade Hydroxypropyl Methylcellulose is a cornerstone excipient in the modern drug industry due to its multifaceted functionality.

Tablet and Granule Coating: One of its primary uses is as a film-forming agent for coating tablets and granules. HPMC creates a smooth, uniform, and durable coating that can protect the active pharmaceutical ingredient (API) from moisture, light, or oxidation, improve appearance, mask unpleasant tastes or odors, and facilitate easier swallowing. Both aqueous and organic solvent-based coating systems utilize HPMC effectively.

Controlled and Extended Drug Release: A significant application is its use as a matrix-forming polymer in controlled or extended-release solid dosage forms. When the tablet or capsule comes into contact with gastrointestinal fluid, HPMC hydrates and swells, forming a viscous gel layer around the core. The drug then diffuses through this gel layer at a controlled rate, allowing for sustained therapeutic levels over an extended period. This property simplifies dosing regimens and improves patient compliance.

Ophthalmic Preparations: In eye drops and artificial tear solutions, HPMC serves as a lubricant and viscosity enhancer. Its ability to increase the viscosity of the solution prolongs the contact time of the medication with the eye's surface, improving therapeutic efficacy. Furthermore, its low irritation potential and osmotic pressure similar to tears make it an ideal component for ophthalmic formulations.

Topical Formulations: As a gelling agent and thickener, HPMC is widely used in semi-solid topical pharmaceuticals like creams, ointments, and gels. It provides the desired consistency, improves the spreadability of the product, and helps in the controlled release of the active ingredient onto the skin.

Tablet Binders: HPMC also functions effectively as a binder in tablet formulations, helping to hold the powdered ingredients together during compression. Unlike some binders, it contributes positively to the disintegration process, ensuring that the tablet breaks down appropriately in the body to release the drug (often described as "good adhesion and collapse dispersion").

Beyond pharmaceuticals, Food Grade Hydroxypropyl Methylcellulose is a valued ingredient in the food industry, recognized by various regulatory bodies for its safety as a food additive (e.g., E464 in Europe). Its functional properties contribute to improved texture, stability, and appearance of food products.

Thickening and Stabilization: HPMC is an excellent thickener and stabilizer in a wide array of food products, including sauces, dressings, soups, gravies, and dairy alternatives. It provides the desired viscosity and prevents the separation of components, ensuring a consistent product throughout its shelf life.

Improving Texture and Mouthfeel: In products like ice cream, sherbets, and frozen desserts, HPMC helps control ice crystal formation, resulting in a smoother, creamier texture and improved mouthfeel. It also contributes to body and structure in baked goods and gluten-free products.

Water Retention: Its hydrophilic nature allows HPMC to effectively bind water, preventing syneresis (water separation) in puddings and gels, and maintaining moisture in baked goods, thus extending their freshness and shelf life.

Protective Glazes and Coatings: HPMC solutions can be used as cold-water glazes or coatings for food items, particularly frozen fish or poultry. This coating forms a protective barrier that minimizes dehydration, prevents freezer burn, and reduces oxidation, thereby preserving the quality, color, and flavor during frozen storage.

Emulsification Stability: It can act as an emulsifying stabilizer, helping to maintain homogenous mixtures in products containing both oil and water phases.

Preventing Deterioration: In specific applications like canned citrus, HPMC can help prevent the deterioration and discoloration that can occur during storage, maintaining the fruit's freshness and appeal.

Ensuring the highest level of quality and purity is paramount for HPMC used in sensitive applications like food and pharmaceuticals. A reputable manufacturer maintains strict quality control systems throughout the entire production process, from raw material sourcing to the final packaged product. This includes rigorous testing for parameters such as viscosity, purity, moisture content, heavy metals, microbial limits, and particle size distribution. Adherence to international standards such as GMP, ISO 9001, USP, and BP is not just a regulatory requirement but a commitment to delivering a safe and effective product. Certificates of Analysis (CoA) should be available for every batch, providing transparency and assurance of quality.

The global market for HPMC is significant, driven by its versatility and the growth of the pharmaceutical and food industries. For companies relying on this essential ingredient, finding a reliable manufacturer and supplier is critical for business continuity and product quality. A trusted partner not only provides consistent, high-quality material but also offers technical support, application guidance, and reliable logistics. Building a long-term relationship with a knowledgeable supplier ensures access to different grades and specifications tailored to specific needs.

When looking to buy or purchase Hydroxypropyl Methylcellulose, it is essential to clearly define your requirements. This includes specifying the desired grade (Food Grade, Pharmaceutical Grade), the required viscosity range, and the intended application, as these factors directly influence the suitable product variant and its price. Quantities required (such as a typical MOQ of 25kg or larger bulk orders) also affect pricing and logistics. It is highly recommended to request samples to test the product's performance in your specific formulation before committing to a large purchase. Experienced manufacturers and suppliers can provide detailed product data sheets, safety information (MSDS), and regulatory documentation. Efficient logistics and flexible packaging options (like aluminum foil bags, cartons, or fiber drums for powder) are also key considerations when choosing a supplier. By partnering with a company committed to quality and customer service, businesses can secure a consistent supply of high-quality HPMC powder, confidently supporting their product development and manufacturing processes.

Hydroxypropyl Methylcellulose (HPMC) powder stands out as a highly functional excipient and additive with indispensable applications across the pharmaceutical and food sectors. Its unique properties as a thickener, stabilizer, film-former, and release modifier make it invaluable. Sourcing this critical material requires careful consideration of grade, quality, and the reliability of the manufacturer and supplier. Choosing a partner with proven expertise ensures access to the high-purity HPMC needed to produce safe, effective, and high-quality final products.

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.