In an era where environmental stewardship is paramount, the global demand for sustainable materials is soaring. One such innovation at the forefront of this movement is high-purity recovered carbon black, a versatile and environmentally responsible alternative to virgin carbon black. Derived meticulously from end-of-life tires, this advanced material represents a significant stride towards a truly circular economy, transforming waste into valuable resources.

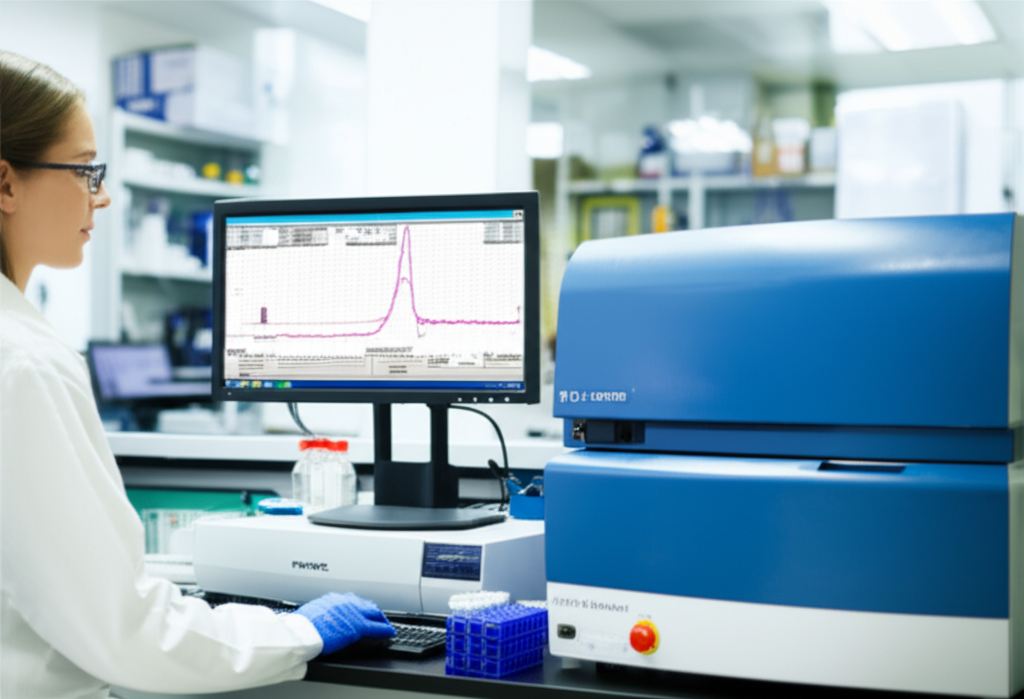

The production of high-purity recovered carbon black involves a sophisticated, multi-stage process designed to maximize purity and performance while minimizing environmental footprint. It begins with the thermal degradation of meticulously screened tires in an oxygen-deprived environment, a process known as pyrolysis. The resulting carbonaceous residue undergoes rigorous post-processing, including advanced iron removal, ultrafine crushing, specialized modification, wet granulation, and precision drying. This intricate refining ensures a product that is not only highly pure but also boasts consistent quality, making it suitable for demanding industrial applications.

This recovered carbon black stands out with its remarkable physical and chemical properties. It typically presents as a spherical granule with a small particle size and a large specific surface area, contributing to its excellent reinforcing capabilities. Users benefit from its high hardness, high constant tensile stress, and low heat generation during processing, which significantly improves the mechanical properties of final products. Furthermore, its inherent flexural resistance and aging resistance ensure durability and extended product lifespan. The material also offers superior processing performance, shortening mixing times and reducing energy consumption in manufacturing processes.

From an environmental perspective, the advantages are profound. The adoption of recovered carbon black drastically reduces reliance on fossil fuels, which are traditionally used in virgin carbon black production. This directly translates to a significant reduction in greenhouse gas emissions – studies indicate up to five times less carbon dioxide is released compared to conventional methods. Moreover, it addresses the critical global challenge of waste tire accumulation, diverting millions of tons from landfills annually and fostering a truly sustainable material cycle.

The versatility of this high-purity material allows for its wide adoption across numerous industries. It is an indispensable component in a variety of rubber products, including but not limited to tire components such as treads, carcasses, inner tubes, cushion belts, and sidewalls. Beyond tires, it enhances the performance of conveyor belts, hoses, industrial rollers, and various rubber shoes. Its application extends into other sectors as well, serving as a critical ingredient in wire and cable insulation, paints, inks, and coatings, as well as in printing and dyeing processes. Depending on the specific formulation and desired properties, this recovered carbon black can effectively substitute various types of virgin carbon black in a range of natural and synthetic rubber systems, offering comparable performance while championing environmental responsibility.

The global industrial landscape is increasingly prioritizing sustainability, with a strong drive towards circular economy models. Major manufacturers across the automotive and consumer goods sectors are actively seeking eco-friendly raw materials to reduce their carbon footprint and meet ambitious environmental targets. Recovered carbon black plays a pivotal role in this transition, offering a robust solution that aligns with both performance requirements and ecological imperatives. Its growing acceptance underscores a collective commitment to responsible manufacturing and a healthier planet.

As a leading manufacturer and reliable supplier of high-purity recovered carbon black, we are dedicated to providing sustainable material solutions that empower industries to achieve their environmental and performance goals. For those looking to purchase a material that combines exceptional quality with environmental integrity, we offer competitive price points and flexible supply options. Our commitment to innovation ensures a steady supply of this critical component for various applications, contributing to a more sustainable and efficient global supply chain. Engage with us to explore how this advanced material can benefit your production and environmental initiatives. We are poised to meet the escalating demand for sustainable raw materials, supporting a future where industrial growth and ecological preservation go hand in hand.

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.