Reinforcing Precipitated Silica Powder stands as a cornerstone raw material within the chemical industry, particularly vital for manufacturers of rubber products. Known chemically as Silicon Dioxide Hydrate (SiO2 * nH2O), with the CAS number 7631-86-9, this fine white powder is not merely a filler but a sophisticated functional additive that significantly elevates the performance characteristics of composite materials. Its primary role is to act as a high-reinforcing agent, fundamentally altering the mechanical properties of the substances it is incorporated into.

The material's efficacy stems from its carefully controlled physical properties. High purity is paramount, ensuring minimal contaminants that could compromise the end product's integrity. Exceptional fluidity and a consistently uniform particle size distribution are also critical, facilitating easy handling, dispersion, and integration into complex formulations. These properties are meticulously monitored according to industry standards like HG/T 3061-2020, along with other key parameters such as BET surface area (typically 170-190 m²/g) and DBP absorption value (ranging from 200-350 10⁻⁵ M³/kg). These specifications are not just technical data points; they are indicators of the powder's ability to interact effectively with polymer matrices, creating strong interfacial bonds essential for reinforcement.

In the rubber industry, the impact of Reinforcing Precipitated Silica Powder is transformative. It is widely recognized for its ability to substantially enhance key performance metrics such as tensile strength, tear resistance, and wear resistance. When added to rubber compounds, it creates a robust network within the material, effectively distributing stress and preventing crack propagation. This leads to products that are more durable, have a longer service life, and can withstand more demanding mechanical stresses. The improvement in mechanical strength and overall toughness makes it an indispensable component for high-performance rubber applications.

A significant advantage of using Reinforcing Precipitated Silica Powder, especially when compared to traditional carbon black, is its inherent light color. While carbon black is an effective reinforcing agent, it invariably results in black rubber products. Precipitated silica, being white, allows for the production of colored or transparent rubber goods without sacrificing reinforcing properties. This opens up a wider range of aesthetic possibilities for manufacturers, from vibrant colored tires to clear shoe soles. Furthermore, the optimized use of silica can contribute to reducing the total amount of filler required or improving processing efficiency, potentially leading to lower overall production costs.

The applications of Reinforcing Precipitated Silica Powder extend across a diverse range of products within the rubber sector. It is a critical ingredient in the manufacturing of high-performance tires, particularly the so-called 'green tires', where it helps reduce rolling resistance, leading to improved fuel efficiency, while maintaining excellent wet grip and tread wear. Shoe soles benefit significantly from silica's reinforcing capabilities, resulting in increased durability, improved traction, and enhanced comfort. Beyond tires and footwear, it is also used in various general rubber goods where strength and wear resistance are essential.

While primarily known for its rubber applications, the versatility of precipitated silica allows it to be used in other fields as well. As indicated by industry practices, specific grades can function as additives in feed, contributing to anti-caking properties and flowability, or even in certain food applications, typically as an anti-caking agent or thickener, provided they meet strict purity and safety standards. This highlights the broad utility of this chemical compound beyond its primary role in mechanical reinforcement.

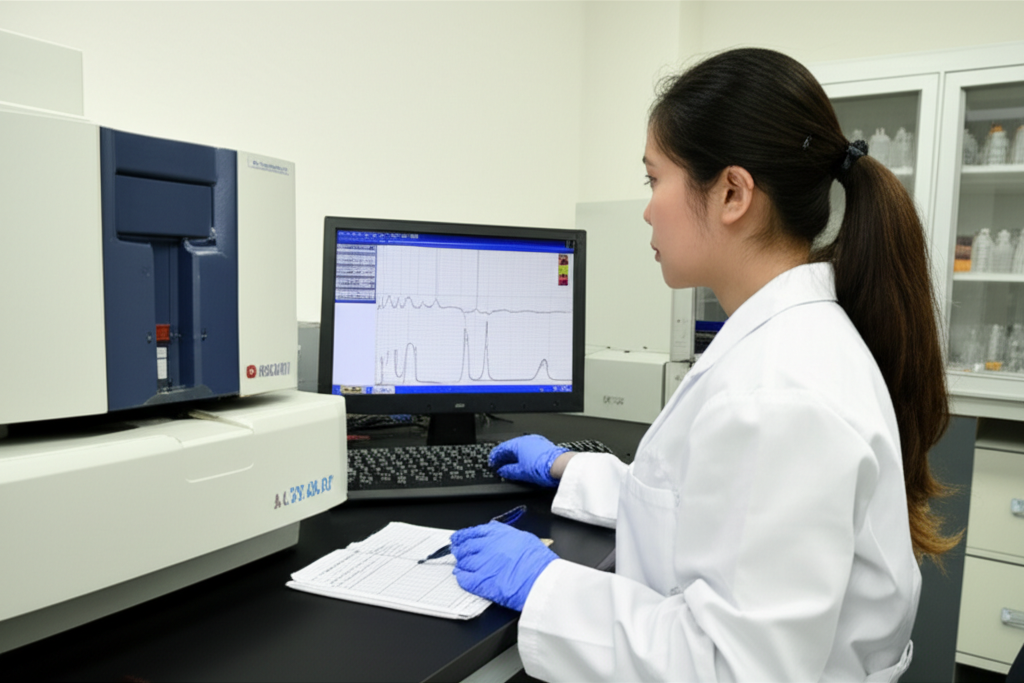

Ensuring consistent quality and reliable supply of Reinforcing Precipitated Silica Powder is crucial for manufacturing operations worldwide. Suppliers who adhere to stringent quality control measures, from raw material sourcing through production to final testing, provide manufacturers with the confidence needed for consistent product performance. Quality certifications such as ISO standards are key indicators of a supplier's commitment to excellence and process control.

For businesses navigating the global market for chemical raw materials, locating a dependable reinforcing precipitated silica powder manufacturer or a specialized precipitated silica supplier for rubber applications is a critical step in the procurement process. Understanding the factors that influence precipitated silica powder price, including purity levels, particle size specifications, quantity requirements, and logistical considerations, is vital for cost-effective sourcing. Prospective buyers often seek detailed information on where to buy precipitated silica that meets their specific technical requirements and quality benchmarks. Researching various precipitated silica powder purchase options available in the market allows procurement teams to identify partners capable of providing not only competitive pricing but also consistent product quality and reliable delivery schedules. NINGBO INNO PHARMCHEM CO.,LTD. is committed to exploring and understanding the dynamics of sourcing high-quality chemical raw materials like Reinforcing Precipitated Silica Powder, providing valuable insights for those seeking to enhance their product formulations and optimize their supply chains.

Manufacturing Facilities

Professional Export Experience

to Global Customers

1. 20 years of R&D, manufacturing and sales experience, serving customers in 60 countries and regions around the world;

2. Own R&D laboratory, pilot platform and large-scale production workshop, which can meet the audit requirements of global customers;

3. We can satisfy customers' perfect transition from small scale lab requirements (gram level) to commercialization requirements (hundred tons level).

A: We don't have Minimum Order Quantity, exact quantity should be provided before quotation for us to calculate the exact cost.

A: We don't provide free samples due to lots of request and expensive international courier's cost, we can deduct the sample charge after commercial order placed.

A: Our payment terms: Small or sample order: T/T IN ADVANCE. Commercial order: First order should be by T/T IN ADVANCE or L/C at sight, and following orders T/T 30~90days is acceptable subject to approval of credit application.