HT301 Desulfurization Agent: Advanced Protective Catalyst for Reforming Processes

Discover the superior performance of the HT301 Desulfurization Agent, a cutting-edge platinum catalyst engineered for the demanding requirements of reforming reactions. This advanced protective desulfurizer ensures optimal feedstock purity and catalyst longevity in your petrochemical operations.

Get a Quote & SampleUnmatched Purity for Critical Reforming Applications

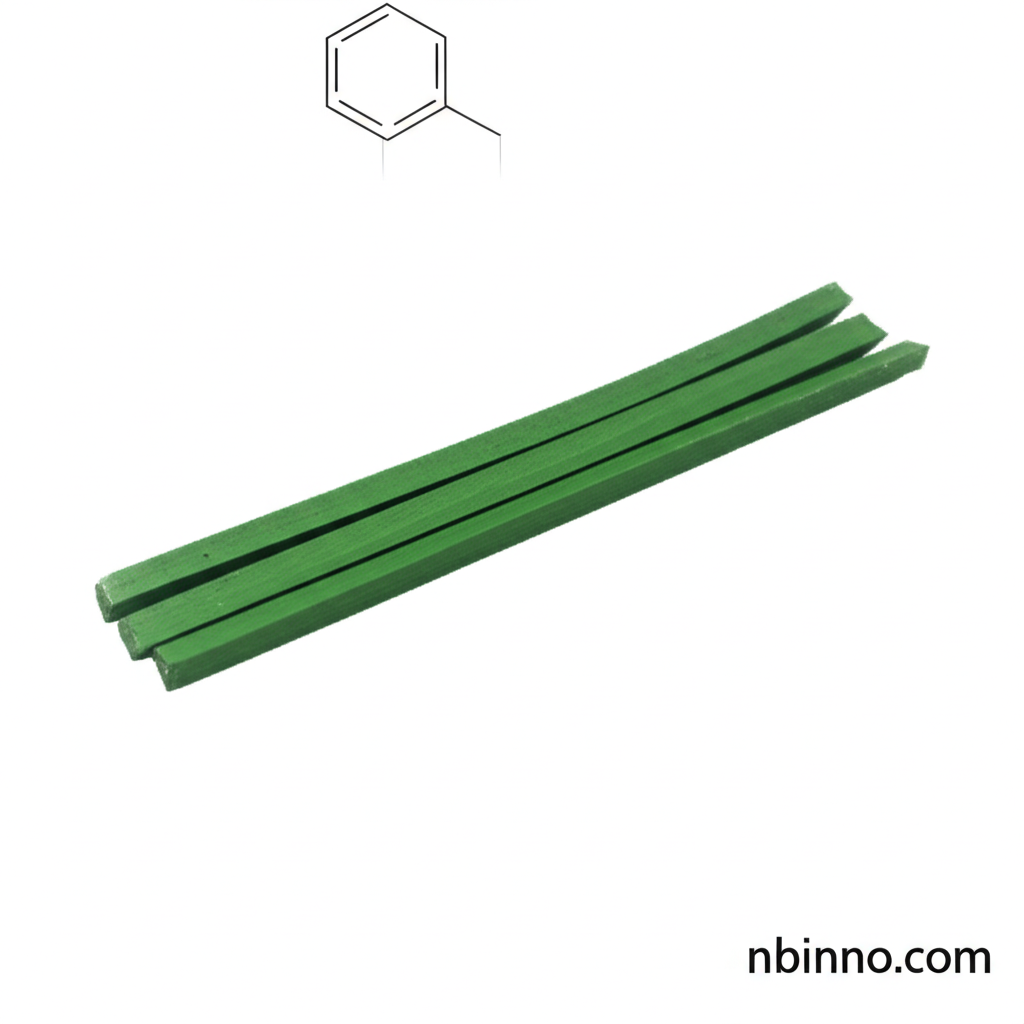

HT301 Desulfurization Agent

As a leading manufacturer and supplier of high-performance catalysts in China, we offer the HT301 Desulfurization Agent, meticulously designed to safeguard your reforming catalysts. Our product ensures that reformed materials meet stringent feed requirements by effectively removing sulfur, arsenic, and chlorine impurities, even under exceptional conditions. Trust our reliable supply chain for your chemical needs.

- Advanced Desulfurization Performance: Effectively removes hydrogen sulfide, other inorganic sulfur, and organic sulfur compounds, making it a crucial component for process optimization and a key reason to buy from a trusted supplier.

- Comprehensive Impurity Removal: Possesses excellent dearsenification and dechlorination capabilities, providing a complete solution for feedstock purification.

- High Strength and Durability: Characterized by high strength and resistance to pulverization, ensuring operational ease and extended service life in your industrial setup.

- Protective Agent for Precious Metal Catalysts: An ideal protective agent for reforming catalysts of precious metals, enhancing their efficiency and lifespan, making it a valuable investment for any refinery.

Key Advantages of HT301 Desulfurization Agent

Superior Impurity Removal Capabilities

The HT301 Desulfurization Agent features nickel and copper as its main active components, supported by special additives and a unique aluminum oxide carrier and dispersing agent. This composition enables efficient removal of various sulfur types, arsenic, and chlorine, crucial for maintaining the integrity of your downstream processes. Consider us your go-to manufacturer for these high-purity chemicals.

Enhanced Operational Efficiency

With its high strength and resistance to pulverization, the HT301 desulfurizer is easy to operate and handle, minimizing downtime and simplifying maintenance. This translates to better overall plant efficiency and cost-effectiveness, a critical factor for procurement managers seeking to optimize operational budgets.

Reliable Protection for Reforming Catalysts

As an ideal protective agent for reforming catalysts, HT301 plays a vital role in preventing catalyst deactivation caused by harmful impurities. This protection is paramount for achieving consistent product quality and yield in catalytic reforming units. If you're looking to purchase this vital catalyst, inquire about our competitive price and availability.

Applications in Petrochemical and Refining Processes

Catalytic Reforming Processes

Essential for catalytic reforming units, HT301 acts as a protective agent, ensuring the purity of feed materials and extending the life of precious metal reforming catalysts. Learn more about how our products can optimize your reforming operations.

Petrochemical Feedstock Purification

Used in various petrochemical industries to purify raw materials and intermediate products, removing detrimental sulfur, arsenic, and chlorine compounds. This application highlights its role in producing high-quality petrochemical feedstocks.

Gas Purification Systems

Applicable in systems requiring high levels of gas purity, such as in the production of synthetic gases or clean fuels, where stringent impurity limits must be met. Our commitment is to provide solutions for cleaner industrial processes.

Pre-Hydrogenation Protection

Serves as a crucial sulfur protective agent installed after pre-hydrogenation steps to further safeguard catalysts from residual impurities, ensuring maximum performance and longevity in demanding refinery environments.