Microcrystalline Cellulose (MCC): Properties, Applications, and Benefits in Pharmaceutical and Food Industries

Discover the essential role of this versatile plant-derived powder in enhancing pharmaceutical formulations and food products.

Get a Quote & SampleProduct Core Value

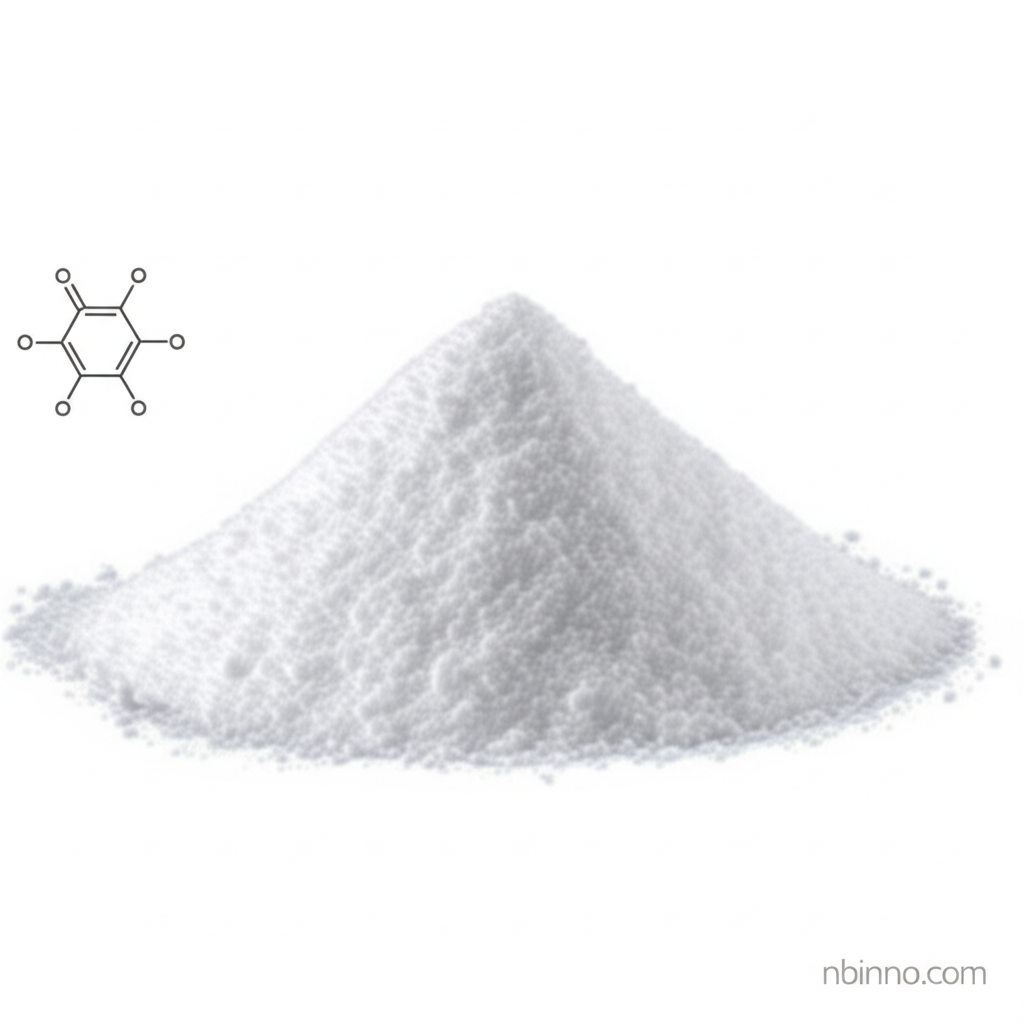

Microcrystalline Cellulose

Microcrystalline cellulose (MCC) is a crucial plant-derived powder renowned for its exceptional properties as a binder, filler, disintegrant, and texturizer. Its chemical inertness and versatility make it an indispensable ingredient in pharmaceuticals, food, and cosmetic industries, ensuring product stability, efficacy, and consumer appeal.

- Leverage the excellent compressibility and binding properties of microcrystalline cellulose for superior tabletability, ensuring robust and uniform tablet formation.

- Ensure product stability with microcrystalline cellulose's chemical inertness, minimizing interactions with active ingredients and maintaining efficacy.

- Enhance drug release and bioavailability by utilizing MCC as a disintegrant, promoting rapid tablet breakdown for optimal absorption.

- Explore the cost-effectiveness and multifunctional advantages of MCC, reducing the need for multiple excipients in pharmaceutical formulations.

Key Advantages

Exceptional Binding and Compressibility

The plasticity of microcrystalline cellulose under compression is key to its exceptional binding properties, allowing for the creation of strong, stable tablets essential for pharmaceutical applications. This also contributes to its use in microcrystalline cellulose tablet formulation.

Chemical Inertness and Safety

Being chemically inert means MCC does not react with active pharmaceutical ingredients, ensuring the integrity and efficacy of medications throughout their shelf life. This safety profile is a cornerstone of microcrystalline cellulose pharmaceutical applications.

Versatile Functional Roles

MCC serves multiple functions, acting as a binder, filler, disintegrant, and more, which simplifies formulations and contributes to the overall cost-effectiveness of drug products, a key aspect of MCC excipient benefits.

Key Applications

Pharmaceutical Formulations

As a binder, filler, and disintegrant, MCC is vital in creating stable and effective tablets and capsules, supporting the efficient delivery of active pharmaceutical ingredients.

Food Production

In the food industry, MCC functions as an anti-caking agent, stabilizer, and texturizer, enhancing the quality and appeal of various processed food products.

Cosmetics and Personal Care

Its properties as an abrasive, absorbent, and viscosity enhancer make MCC a valuable ingredient in skincare, haircare, and makeup products for improved texture and feel.

Dietary Supplements

MCC is commonly used in vitamin supplements and other dietary products as a bulking agent and binder, contributing to pill integrity and formulation stability.