High-Quality Polymethylene Polyphenylene Ester (CAS 9016-87-9): Properties, Applications, and Industrial Use

Discover the versatile properties and extensive applications of Polymethylene Polyphenylene Ester, a vital component in modern industrial materials. Explore its role in creating advanced polyurethanes.

Get a Quote & SampleProduct Core Value

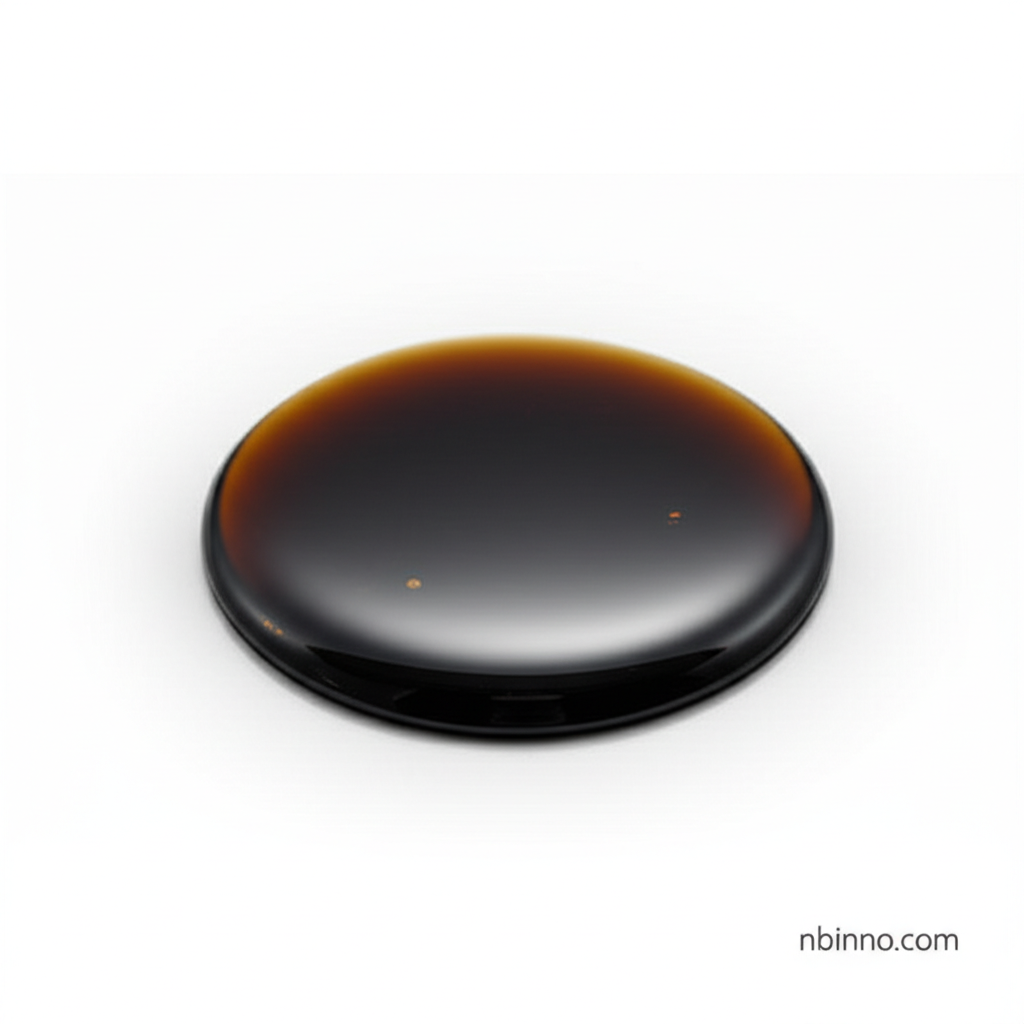

Polymethylene polyphenyl ester

As a leading manufacturer in China, we provide super quality Polymethylene Polyphenylene Ester (CAS 9016-87-9) with a 99% minimum assay. This essential chemical intermediate plays a crucial role in various industrial applications, renowned for its high reactivity and ability to form strong polyurethane systems. We are dedicated to offering competitive pricing and supporting online purchases for this high-quality industrial chemical.

- Leveraging our expertise as a supplier in China, we ensure consistent quality for Polymethylene Polyphenylene Ester, crucial for precise Polyurethane Chemistry Innovations.

- This material is instrumental in creating advanced Polyurethane Foams, offering excellent insulation and structural integrity for diverse applications.

- We facilitate the sourcing of industrial chemicals, making it easier to buy Polymethylene Polyphenylene Ester for your manufacturing needs.

- The high NCO content of Polymethylene Polyphenylene Ester ensures superior performance in Adhesives and Coatings, providing enhanced durability and resistance.

Key Advantages Offered

Enhanced Material Performance

The high reactivity of Polymethylene Polyphenylene Ester allows for strong crosslinking, significantly boosting the mechanical strength and thermal stability of resulting materials, crucial for advanced material synthesis.

Versatile Application Range

From rigid polyurethane foams used in construction to durable adhesives and protective coatings, this chemical intermediate is a cornerstone for a wide array of industrial applications.

Consistent Quality Assurance

As a reputable manufacturer in China, we guarantee a high assay of Polymethylene Polyphenylene Ester, ensuring reliability and predictable performance in your Chemical Intermediate Manufacturing processes.

Key Applications

Polyurethane Foams

Critical for producing rigid and flexible polyurethane foams used in insulation, furniture, and automotive interiors, enhancing comfort and energy efficiency through effective Polyurethane Chemistry Innovations.

Adhesives & Sealants

Provides strong bonding capabilities for various substrates, essential for industrial adhesives and construction sealants where durability is paramount, making it a key component for Chemical Synthesis.

Protective Coatings

Imparts excellent durability, chemical resistance, and weatherability to coatings used in industrial and marine environments, contributing to the longevity of protected surfaces.

Composite Materials

Serves as a binder or matrix component in reinforced plastics and high-performance composites, leveraging its strength-enhancing properties for demanding applications.