Glass Bead Blasting Media: Achieve Superior Surface Finishes

Explore the benefits of glass bead abrasive media for your sandblasting needs, offering precision cleaning, peening, and a perfect satin finish for various materials.

Get a Quote & SampleProduct Core Value

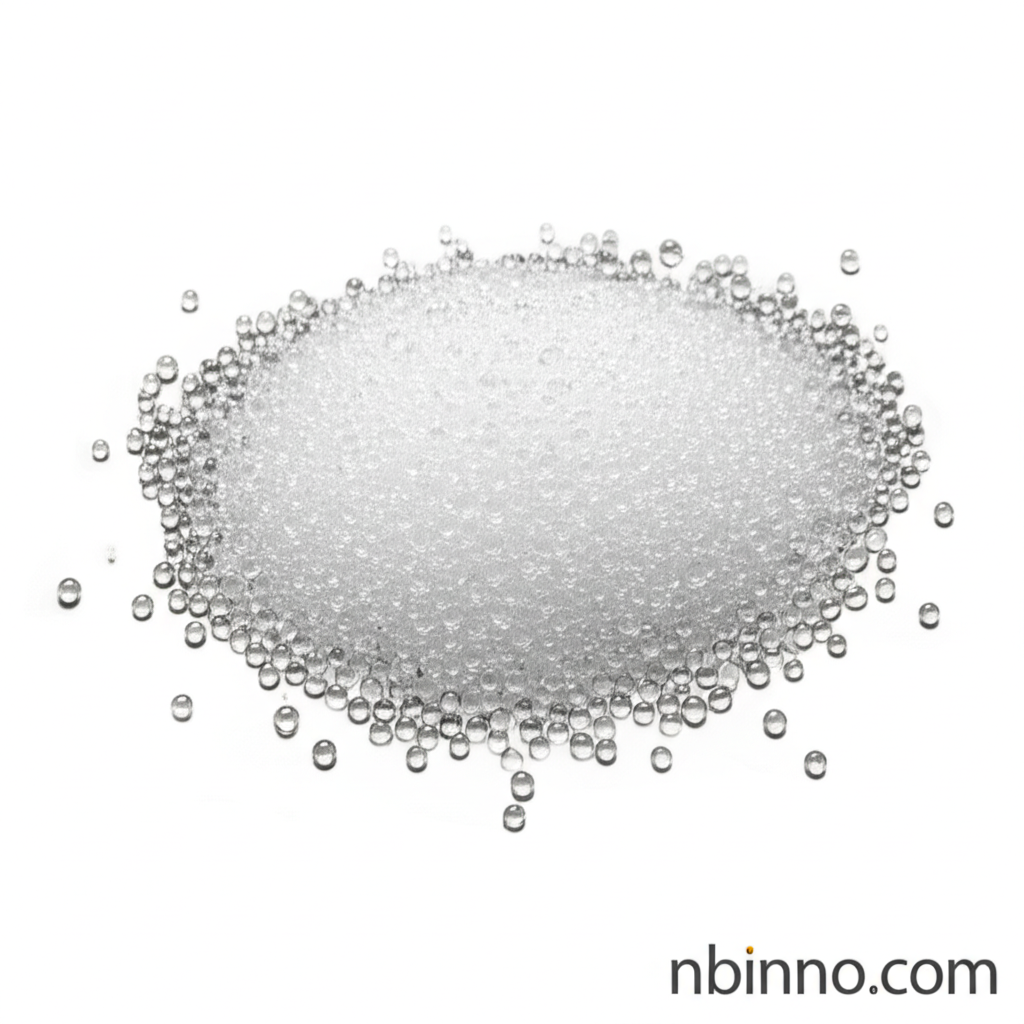

Glass Beads for Sandblasting

As a leading supplier in China, we offer high-quality glass bead blasting media that provides exceptional results for surface finishing and peening applications. Our media is known for its chemical stability and high mechanical intensity, ensuring durability and effectiveness. We are a trusted manufacturer in China, providing reliable solutions for a wide range of industrial needs.

- Achieve a pristine satin or matte finish with our precision-engineered glass bead abrasive media, perfect for delicate surfaces and ensuring a consistent aesthetic.

- Benefit from minimal dimensional changes to your parts, making our glass beads ideal for high-precision components where tolerances are critical.

- Utilize media that is chemically inert and contains no free silica, ensuring a clean blasting process and preventing unwanted residues or health hazards.

- Leverage the recyclability of our glass bead media, allowing for multiple uses and reducing overall operational costs while maintaining consistent performance.

Advantages of Using Our Glass Bead Media

Enhanced Surface Quality

Our glass bead blasting media is engineered to deliver a bright, uniform satin-like appearance, significantly improving the aesthetic appeal and tactile feel of your finished products.

Versatile Application

Whether for cleaning, polishing, peening, or deburring, our glass beads are suitable for a wide array of industrial sandblasting applications, meeting diverse project requirements.

Environmentally Conscious Choice

Made from lead-free glass, our beads are chemically inert and silica-free, making them an environmentally friendly and safer alternative to many other abrasive media options.

Key Applications

Metal Finishing

Our glass beads are excellent for achieving a superior surface finish on various metals, ideal for automotive restoration and precision component manufacturing.

Peening

Effectively used for shot peening to reduce tensile stress in metal components, thereby increasing fatigue life and stress corrosion resistance.

Cleaning and Deburring

Easily remove light burrs, carbon deposits, and surface contaminants without altering critical part dimensions, ensuring optimal performance.

Glass Etching

Achieve decorative frosting and etching effects on glass surfaces with controlled precision, perfect for artistic or functional glass applications.